Description

The HPS 1.5-3.5 pumps are designed with two ports and are primarily used in pump group systems. These pumps are not self-priming, meaning that the inlet pressure must always be positive. If the inlet pressure cannot be maintained, it will lead to permanent damage to the pump.

To ensure proper operation, the simplest method is to disconnect the pump’s inlet pipe and measure the flow. When the water tank’s liquid level is at its lowest, the water supply flow should be at least 20% higher than the pump’s delivery flow. This ensures that the inlet pressure remains positive while the pump is running.

Do not install a filter between the pump and a direct water supply from the water tank, unless a pressure switch is installed on the inlet pipe to prevent negative pressure from affecting the pump.

Electric Pump Set:

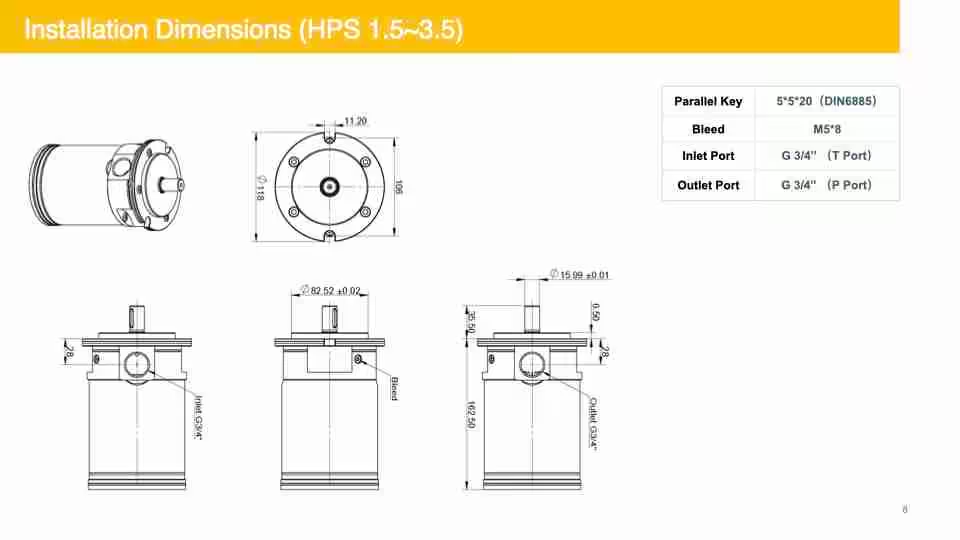

Use a standard bell housing and coupling to connect the pump to the B5 motor flange. The pump should not be operated under axial or radial loads on the output shaft. Gear couplings are recommended wherever possible to avoid such loads.

Operating Temperature:

The HPS 1.5-3.5 pumps are designed to operate within a temperature range of 2°C to 50°C for optimal performance. For temperatures below freezing, an environmentally friendly antifreeze is required. The pump can also operate at temperatures above 50°C, but this may reduce its volumetric efficiency. If operating above 50°C, the maximum operating temperature should be specified when ordering.

Filtration:

All water entering the pump must be pre-filtered to a nominal rating of 10 microns (absolute value of 25 microns). For closed-loop systems, backflow filtration is acceptable. High-pressure filtration is also possible, but it is generally more expensive.

Fluid Compatibility:

The standard version of the pump works well with drinking water and industrial water, such as distilled water, reverse osmosis water, or demineralized water. Depending on the specific operating environment, changes to sealing materials or construction may be necessary.

The standard construction is suitable for seawater, but due to the increased corrosion potential, long-term operation in seawater may require higher-grade materials to ensure durability and performance.

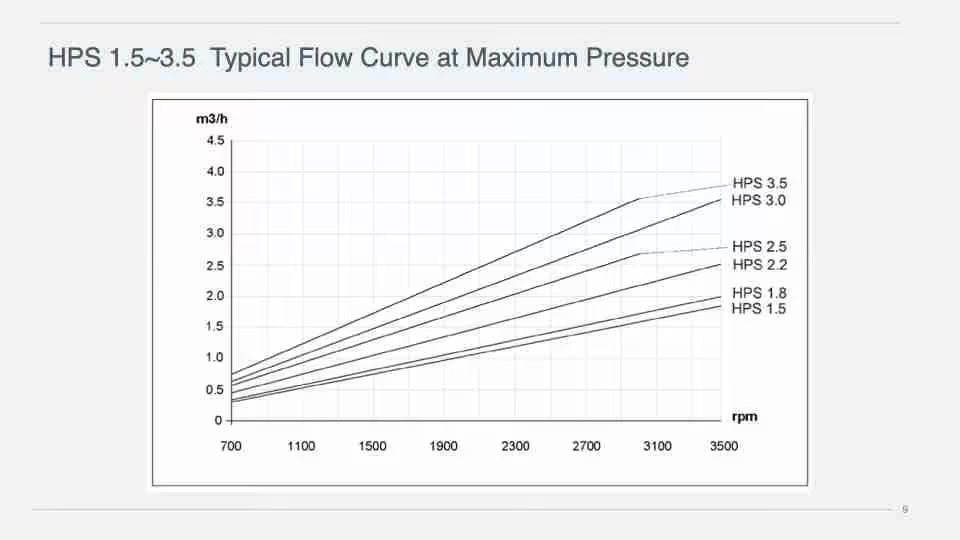

| Pumps Model | 1.5 | 1.8 | 2.2 | 2.5 | 3.0 | 3.5 |

| Displacement (cc/rev) | 9.34 | 10.21 | 12.75 | 15.4 | 17.85 | 21.56 |

| Housing Material | 2205 | 2205 | 2205 | 2205 | 2205 | 2205 |

| Min. Outlet Pressure(barg) | 20 | 20 | 20 | 20 | 20 | 20 |

| Max. Outlet Pressure(barg) | 85 | 85 | 85 | 85 | 85 | 85 |

| Inlet Pressure Continuous (barg) | 0.5-5 | 0.5-5 | 0.5-5 | 0.5-5 | 0.5-5 | 0.5-5 |

| Flow Rate (m3/h) (85barg, 700 rpm) | 0.3 | 0.34 | 0.45 | 0.57 | 0.64 | 0.76 |

| Flow Rate(m3/h) (85barg, 1000 rpm) | 0.54 | 0.58 | 0.75 | 0.90 | 1.03 | 1.24 |

| Flow Rate(m3/h) (85barg, 1200 rpm) | 0.58 | 0.64 | 0.84 | 1.03 | 1.18 | 1.39 |

| Flow Rate (m3/h) (85barg, 1500 rpm) | 0.80 | 0.87 | 1.10 | 1.34 | 1.55 | 1.88 |

| Flow Rate (m3/h) (85barg, 1800 rpm) | 0.92 | 1.0 | 1.27 | 1.58 | 1.80 | 2.11 |

| Flow Rate (m3/h) (85barg, 2500 rpm) | 1.31 | 1.42 | 1.80 | 2.22 | 2.55 | 2.98 |

| Flow Rate (m3/h) (85barg, 3000 rpm) | 1.60 | 1.73 | 2.18 | 2.68 | 3.07 | 3.58 |

| Flow Rate (m3/h) (85barg, 3500 rpm) | 1.84 | 1.99 | 2.52 | 3.56 |