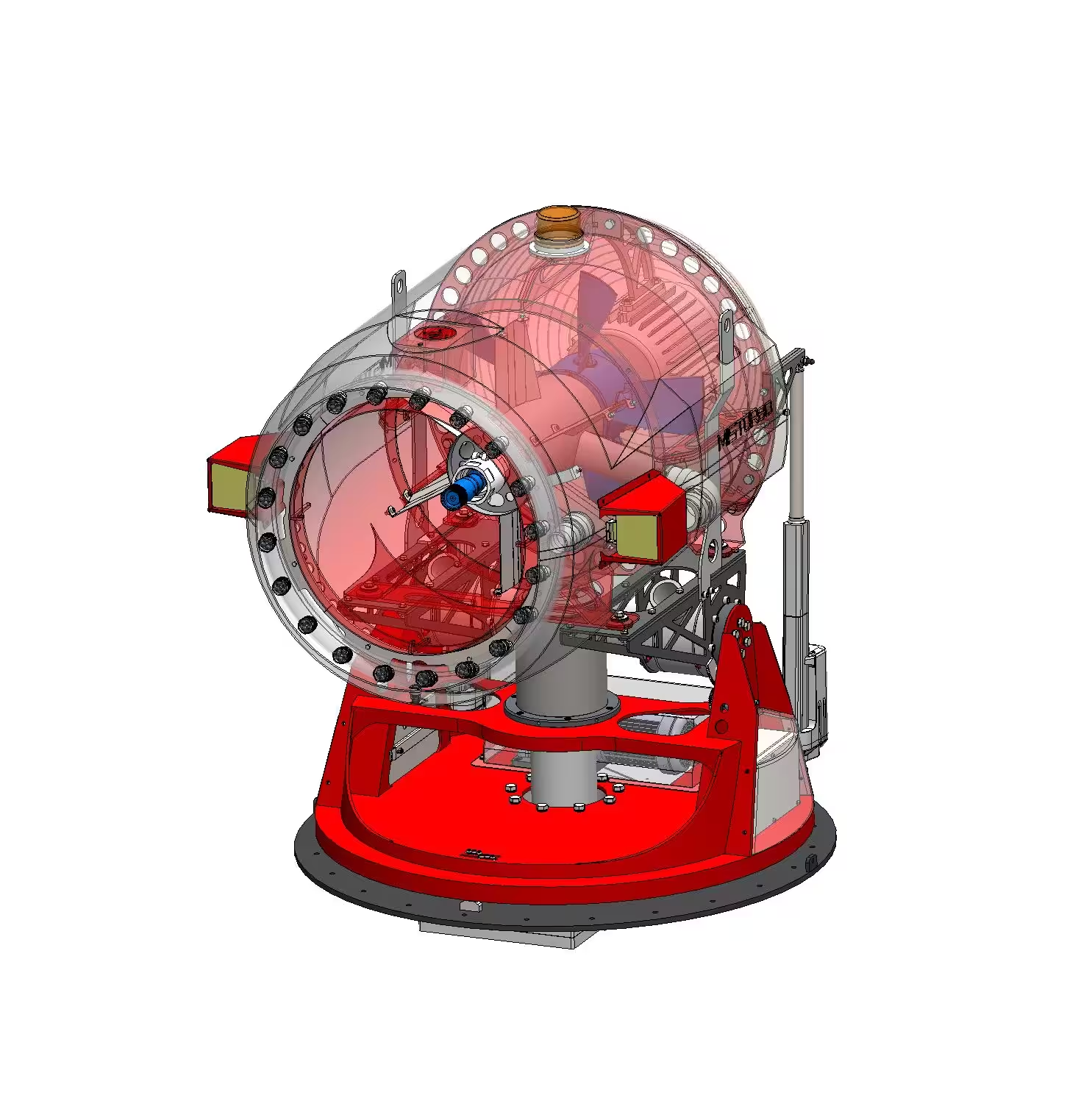

In modern industrial and firefighting applications, high-pressure water mist systems are rapidly emerging as efficient and eco-friendly solutions. As the core component of these systems, the choice of a high-pressure pump directly impacts the system’s performance and reliability. Axial piston high-pressure pumps, with their oil-free lubrication, corrosion resistance, and high efficiency, have become a preferred choice for various high-pressure water mist applications, providing dependable support for industrial operations and safety measures.

Table of Contents

ToggleFeatures of Axial Piston High-Pressure Pumps

1. Oil-Free Lubrication Design

Axial piston pumps utilize water as a lubricant, eliminating the contamination risks associated with traditional oil-based systems. This ensures the purity of the output water, making them ideal for applications requiring high cleanliness, such as spray humidification or material separation.

2. High-Quality Materials

Constructed from materials like 2205/2507 duplex steel, 316L or 304 stainless steel, these pumps offer exceptional corrosion resistance and prolonged durability. Even in high-pressure and corrosive environments, they maintain stable performance.

3. High Efficiency and Low Maintenance

Axial piston pumps exhibit low pulsation characteristics and excellent mechanical efficiency. This enhances operational stability, reduces maintenance frequency, and lowers long-term operational costs.

Key Applications of Water Mist Pumps

Water Mist Firefighting Systems

High-pressure water mist systems use micron-sized water droplets to achieve rapid cooling and oxygen isolation. Axial piston pumps provide a continuous, stable high-pressure water supply, making them ideal for building fire protection and industrial fire safety.

High-Pressure Cleaning

For industrial equipment cleaning, the high-pressure capabilities of water mist pumps effectively remove stubborn contaminants. Their oil-free lubrication ensures the cleaning process is environmentally friendly.

Spray Humidification

In industries like textiles and electronics, spray humidification systems utilize high-pressure pumps to atomize water, ensuring uniform humidity levels while reducing static electricity and dust.

High-Pressure Leachate Reverse Osmosis

In landfill leachate treatment or industrial wastewater processes, high-pressure water mist pumps act as the core component of reverse osmosis systems, enabling efficient separation and purification of liquids under high pressure.

Material Separation and High-Pressure Water Supply

In sectors like food processing and pharmaceuticals, high-pressure pumps facilitate material separation or efficient water delivery under high pressure, achieving automation and process optimization.

Technical Advantages of Axial Piston Pumps

1. Environmental Benefits

The oil-free lubrication design completely eliminates cross-contamination risks between oil and water, providing an environmentally friendly solution for high-pressure systems.

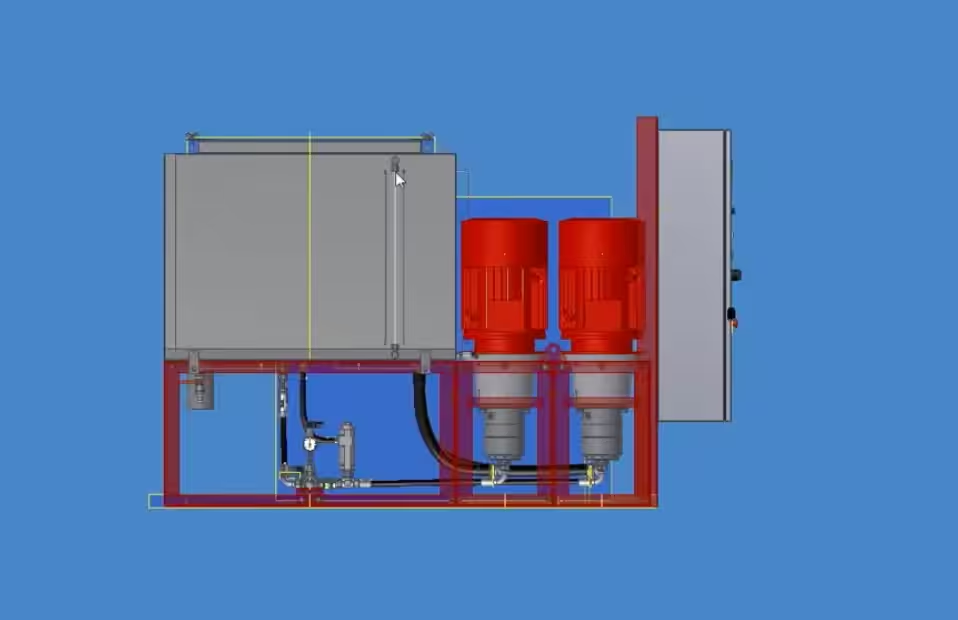

2. Stability and Low Maintenance Costs

With a multi-piston design, axial piston pumps minimize pressure fluctuations during operation. This design enhances stability, extends the pump’s service life, and reduces maintenance frequency and costs.

3. Flexible Adaptability

The modular design of these pumps allows for easy installation, disassembly, and maintenance. Additionally, various configurations and models make them suitable for diverse application requirements.

Case Studies and Industrial Value

- Applications in Water Mist Firefighting Systems

In a high-rise building firefighting system, axial piston high-pressure pumps demonstrated rapid activation and efficient firefighting capabilities, significantly reducing fire damage during critical moments. Moreover, water mist systems consume only 10% of the water used by traditional sprinkler systems, making them highly resource-efficient. - Typical Scenarios in Other High-Pressure Applications

In industrial cleaning and spray humidification, axial piston pumps provide enhanced operational efficiency through high-pressure boosting while meeting environmental and energy-saving demands. For instance, in electronics manufacturing, spray humidification prevents static electricity risks, making water mist pumps essential for maintaining optimal conditions.

Conclusion and Future Outlook

Axial piston high-pressure pumps, known for their efficiency, stability, and eco-friendliness, play a vital role in water mist pump systems. Looking ahead, with continuous technological advancements, high-pressure water mist pumps are expected to find deeper and broader applications across industries. They not only improve operational efficiency but also serve as critical components in promoting green and sustainable development. If you are interested in details of axial piston high pressure pumps, you can feel free to download the catalogs here.