This article is a general guide for RO system engineers. For containerized SWRO high pressure pump selection with ERD/VFD integration, refer to this selection guide.

Reverse osmosis (RO) systems are often described as “membrane systems”, but in real operation, pumps define whether the system works reliably or not.

Different pumps inside an RO system serve very different purposes. Some only enable flow. Others define pressure, stability, and long-term operating cost. Understanding which pumps are used, what role they play, and how their lifespan should be understood is essential for system designers and operators.

This article looks at RO pumps from a system and lifecycle perspective, not just a component list.

Table of Contents

ToggleRO system pump map (from inlet to outlet)

An RO system is not driven by a single pump. It is a chain of pumps, each operating at a different pressure level and performing a specific function.

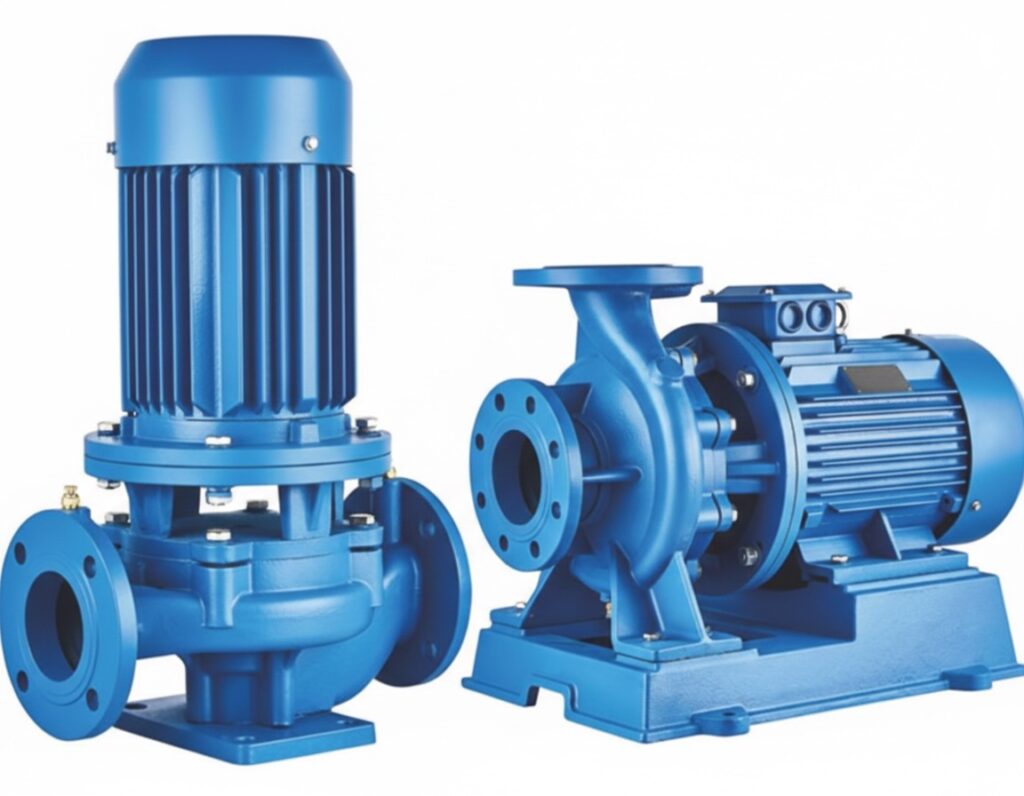

Feed / intake pump (low pressure)

The feed or intake pump brings raw water into the RO system.

- Typical pressure: low (often < 3 bar)

- Main function: provide stable flow to pretreatment and downstream pumps

- Common type: centrifugal pump

From a system point of view, this pump does not define RO performance, but unstable feed flow will propagate problems downstream.

Booster pump (medium pressure)

Booster pumps are used when incoming pressure is insufficient.

- Typical pressure range: household RO ~3–7 bar, light commercial systems slightly higher

- Function: ensure adequate pressure at the RO membrane inlet or high-pressure pump suction

- Common types: diaphragm pumps (small systems), small centrifugal pumps (commercial systems)

In most RO systems, the booster pump is a supporting component, not a system limiter.

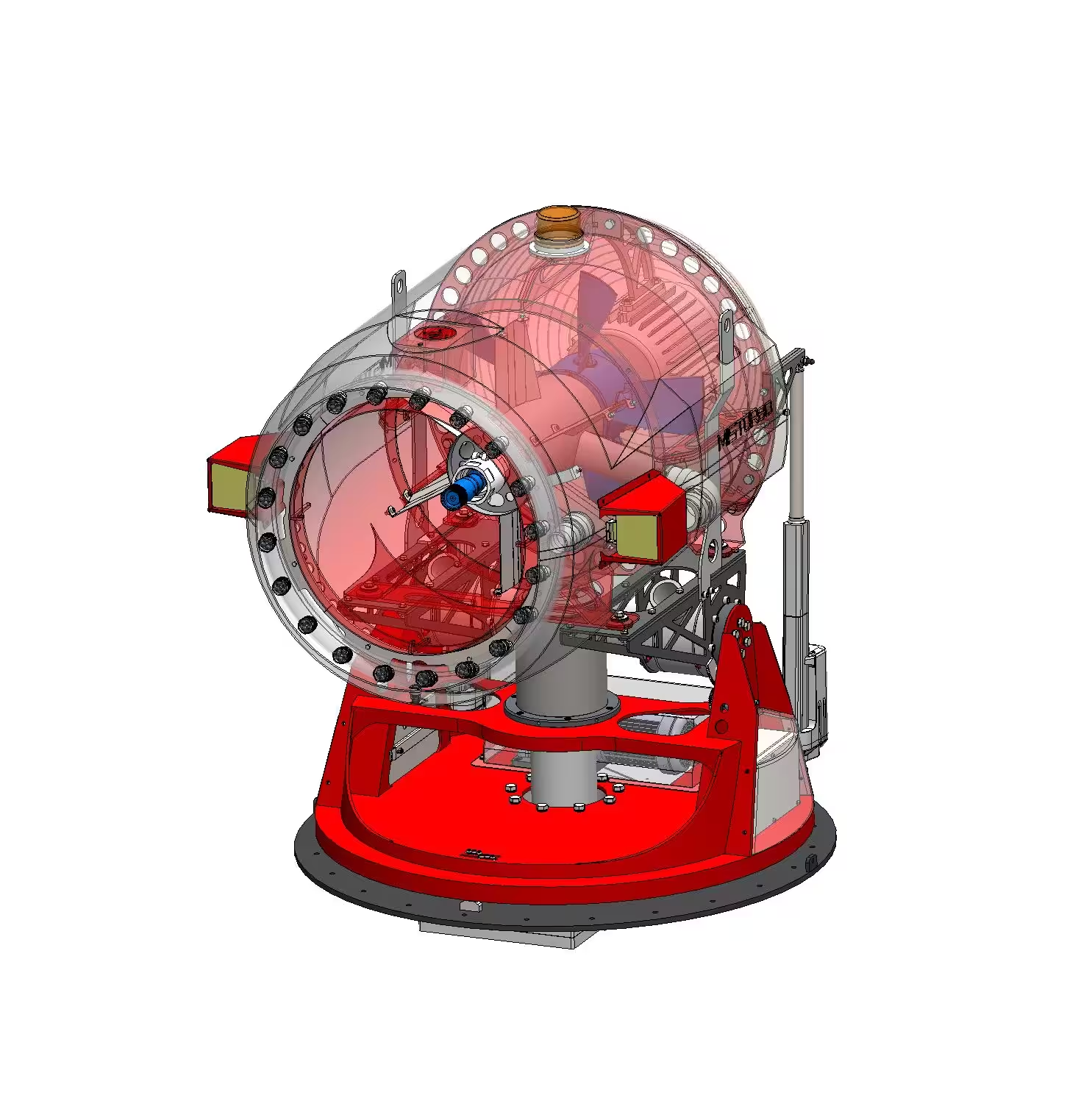

High pressure pump (RO core, high pressure)

The high pressure pump is the heart of any RO system.

- Function: generate the pressure required to overcome osmotic pressure and membrane resistance

- Pressure level:

- Brackish RO (BWRO): typically 10–30 bar

- Seawater RO (SWRO): typically 55–70 bar (with higher margins for design)

This pump directly determines:

- System stability

- Energy consumption

- Membrane performance

- Long-term maintenance cost

Unlike other pumps in the system, mistakes here cannot be compensated elsewhere.

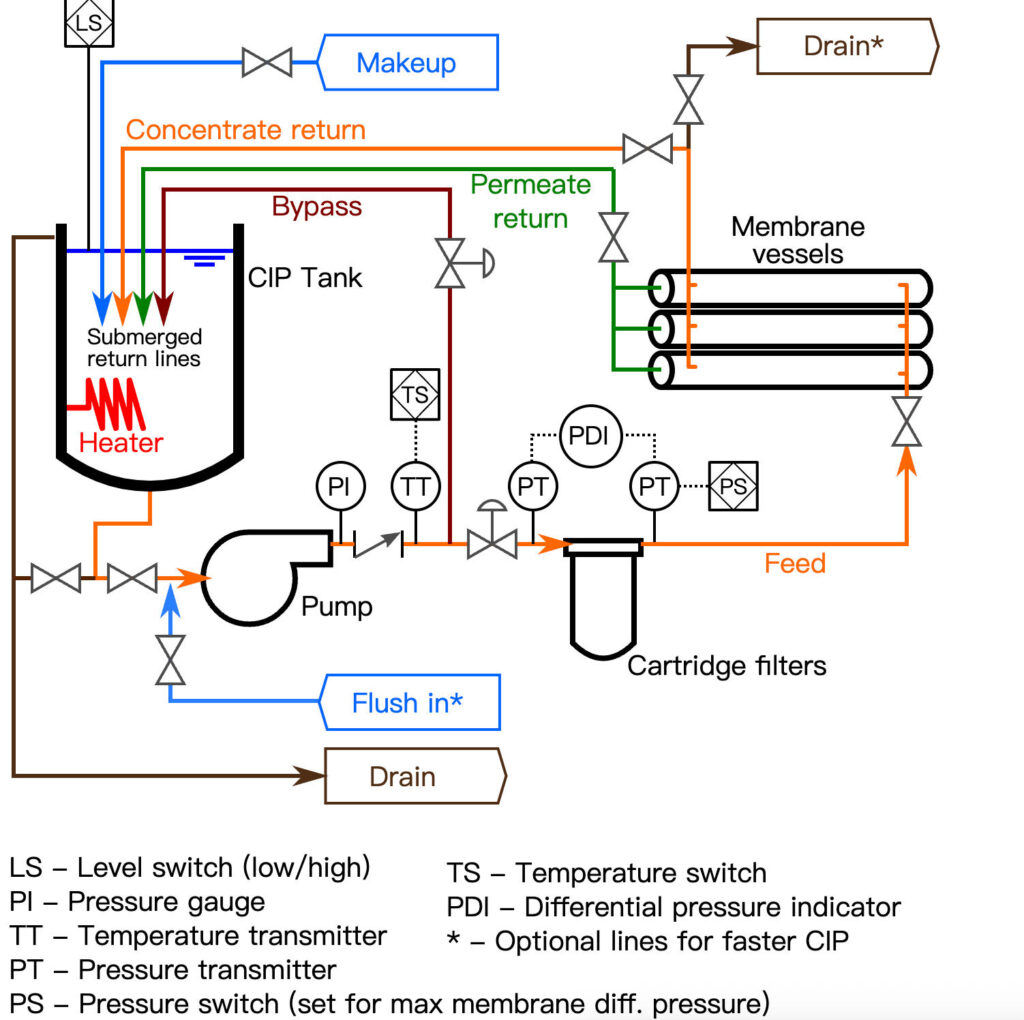

CIP pump (cleaning)

CIP (Clean-In-Place) pumps circulate cleaning solutions during membrane cleaning.

- Operate intermittently

- Low to medium pressure

- Chemical compatibility is more important than pressure capability

CIP pumps do not affect daily RO performance but influence membrane recovery and long-term system health.

Chemical dosing pump

Chemical dosing pumps inject antiscalants, biocides, or pH adjustment chemicals into the RO feed stream.

- Very low flow

- Precise and stable dosing required

- Common types: diaphragm metering pumps

These pumps do not influence RO pressure or hydraulic performance directly, but play a critical role in protecting membranes and maintaining long-term system stability by controlling scaling, fouling, and biological growth.

Permeate transfer / distribution pump

Once water passes through the RO membrane, a permeate pump may be used to transfer, store, or distribute treated water.

- Low pressure duty

- Typically centrifugal pumps

- Sized based on downstream distribution requirements rather than membrane design

From an RO process perspective, permeate pumps do not influence membrane separation, operating pressure, or recovery ratio.

They function purely as downstream handling equipment and are not a limiting factor in RO system performance.

Which pump is the “key pump” in RO?

The high pressure pump.

Every other pump in an RO system supports the process.

The high pressure pump defines the process.

From an engineering perspective, the high pressure pump is the only pump that simultaneously determines:

- whether membranes operate within a stable pressure window

- how efficiently osmotic pressure is overcome

- whether energy recovery (where applicable) can function correctly

- how predictable long-term maintenance and operating cost will be

If the feed pump, booster pump, or permeate pump is poorly selected, the system may still run—often with reduced efficiency or convenience.

If the high pressure pump is poorly selected, no amount of downstream adjustment can compensate for it.

In practice, the majority of RO system performance issues—unstable pressure, premature membrane fouling, excessive energy consumption, or early mechanical failures—can be traced back to how the high pressure pump is selected, integrated, and operated within the system.

Typical pump lifespan — what does “lifespan” really mean?

Pump lifespan is often misunderstood as a single number.

From an engineering perspective, it consists of three different layers:

- Design life

The expected service life of the pump structure under proper operating conditions. - Overhaul interval

The period between major maintenance actions. - Wear part life

Seals, bearings, and other consumables that require periodic replacement.

When someone asks, “How long does this pump last?”, the correct answer is always:

“Which part of the pump, under which operating conditions?”

Lifespan by pump type (realistic ranges and Conditions)

Booster pumps (household and small commercial RO)

Booster pumps are commonly used in household and small commercial RO systems.

Under normal residential or light commercial operating conditions, a typical booster pump lifespan is around 3–5 years.

It is important to understand that this range assumes intermittent operation, moderate inlet water quality, and basic maintenance. Outside these conditions, service life can be significantly shorter.

Key factors that influence booster pump lifespan include:

- Water quality

Suspended solids, high hardness, or particulate contamination increase internal wear.

Inadequate pre-filtration often leads to accelerated seal and diaphragm degradation. - Operating frequency

Booster pumps are not designed for continuous duty.

Frequent start-stop cycles and long daily operating hours accelerate mechanical and electrical wear. - Maintenance practices

Periodic inspection, cleaning, and timely replacement of wear parts are essential.

Neglected booster pumps typically fail electrically or mechanically rather than hydraulically.

From a system perspective, booster pump lifespan is usage-driven, not model-driven.

A well-selected pump can still fail early if used outside its intended duty cycle.

High pressure pumps (industrial RO duty)

High pressure pumps used in industrial RO systems typically exhibit a structural service life of 5–10 years or longer, provided they operate within their designed envelope.

This range refers to the pump assembly, not consumable components such as seals or bearings, which require periodic replacement.

Compared with booster pumps, high pressure pumps face much stricter durability requirements due to:

- Continuous operation

- Elevated pressure levels

- Higher mechanical and thermal loading

Primary factors affecting high pressure pump lifespan include:

- Design and manufacturing quality

Material selection, internal tolerances, and surface finishing directly affect fatigue life and wear resistance.

High-quality pumps shift failure risk from early-life defects to predictable maintenance cycles. - Operating conditions

Sustained operation near maximum pressure, excessive temperature, or unstable suction conditions significantly reduce service life.

Pumps designed for high pressure still require a defined operating margin to remain reliable over time. - Maintenance and servicing

Regular professional maintenance — including seal replacement, wear-part inspection (water-lubricated interfaces/bearings as applicable), flushing verification, filtration review, and full system inspection — is essential.

For oil-free axial piston high pressure pumps, there is no oil-lubrication service requirement, but stable water quality, proper flushing, and correct operating envelope remain critical to long-term reliability. failures.

In practical RO projects, high pressure pump lifespan is determined more by system integration and operating discipline than by the pump itself.

Engineering clarification: why lifespan numbers vary so widely

When engineers report vastly different pump lifespans for similar equipment, the reason is rarely the pump model.

Differences usually arise from:

- Operating pressure relative to design range

- Filtration quality and flushing strategy

- Start-up and shutdown logic

- System control stability

For this reason, lifespan figures should always be interpreted as conditional ranges, not guaranteed outcomes.

What shortens pump life fastest (top 6)

Across RO projects, the same failure accelerators appear repeatedly:

- Dry running – even brief loss of lubrication can cause irreversible damage

- Cavitation – often due to poor suction conditions or inadequate booster support

- Insufficient filtration – abrasive particles accelerate wear

- Frequent start-stop cycles – thermal and mechanical stress accumulates

- Continuous operation near maximum pressure – reduces safety margin

- No proper flushing – salt crystallization and deposits during shutdown

Most of these are system design or operation issues, not pump manufacturing defects.

Practical maintenance signals to watch

High pressure pumps rarely fail without warning. Common early indicators include:

- Increasing vibration levels

- Abnormal noise patterns

- Gradual flow reduction at constant speed

- Visible leakage at seals

- Rising operating temperature

Monitoring these signals allows maintenance to be planned instead of reactive.

When to choose axial piston vs multistage pumps (guidance only)

Both axial piston and multistage centrifugal pumps are used in RO systems.

As a general guide:

- Systems with variable operating conditions, frequent speed adjustment, or tight pressure control benefit from positive displacement behavior

- Systems operating close to a fixed design point may tolerate centrifugal solutions

If you are designing containerized SWRO systems with VFD and ERD integration, pump behavior under partial load and dynamic conditions becomes critical.

👉 If you are building containerized SWRO systems with VFD + ERD, see our detailed selection guide here:

How to Select a High Pressure Pump for Containerized SWRO Systems

Final engineering takeaway

RO systems are not limited by membranes alone.

They are limited by how pressure is generated, controlled, and sustained over time.

Pump lifespan is not determined by catalog numbers, but by system design choices, operating discipline, and how well the pump fits its real operating envelope.

If your RO system is experiencing:

- unstable operating pressure

- higher-than-expected maintenance frequency

- premature seal or bearing failures

- difficulty integrating VFDs or energy recovery devices

these are often system-level issues, not isolated pump problems.

At Rohre Pumps, we work with system integrators and project engineers to evaluate pump selection in the context of the entire RO system, not just flow and pressure on paper.

If you are planning a new RO project—or troubleshooting an existing one—and want to verify whether your pump selection truly fits your operating conditions, feel free to contact Rohre Pumps for an engineering-level discussion.