Water Mist Pump Manufacturer

For Fire Suppression, High Pressure Cleaning Systems, RO, Humidification Systems.

What Is a Water Mist Pump for Humidification Systems

A high-pressure water mist pump in humidification systems is designed to significantly increase water pressure, enabling the atomization of water into a fine mist for effective humidification. These high-pressure pumps utilize an axial piston design, are completely oil-free, and rely on water for lubrication, ensuring no oil contamination in the output mist. Constructed from materials like Duplex and Super Duplex stainless steel, these pumps offer enhanced durability and corrosion resistance, making them ideal for long-lasting performance in demanding industrial and environmental conditions.

HPH Series Water Mist Pump for Tap Water

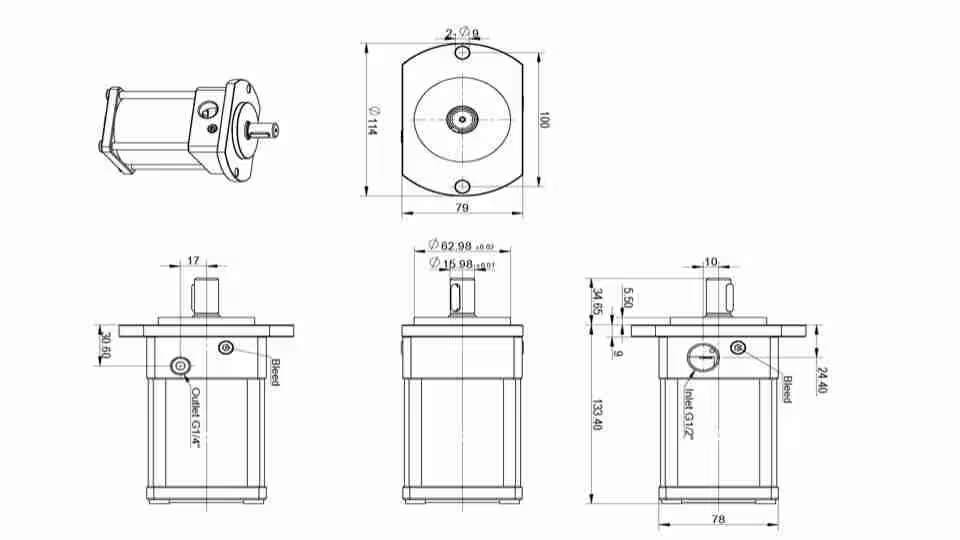

| Pumps Model | 2.0 | 3.2 | 4.0 | 6.3 |

| Displacement (cc/rev) | 2 | 3.2 | 4 | 6.3 |

| Housing Material | ASTM 304 / ASTM 316L | ASTM 304 / ASTM 316L | ASTM 304 / ASTM 316L | ASTM 304 / ASTM 316L |

| Min. Outlet Pressure(barg) | 30 | 30 | 30 | 30 |

| Max. Outlet Pressure(barg) | 140 | 140 | 140 | 140 |

| Inlet Pressure,Continuous(barg) | 0-4 | 0-4 | 0-4 | 0-4 |

| Min. Speed,Continuous (rpm) | 700 | 700 | 700 | 700 |

| Max. Speed (rpm) | 1800 | 1800 | 1800 | 1800 |

| Flow Rate (L/min) (14Mpa,700 rpm) | 0.3 | 1.3 | 1.9 | 3.7 |

| Flow Rate (L/min) (14Mpa,1000 rpm) | 1.0 | 2.3 | 3.2 | 5.6 |

| Flow Rate (L/min) (14Mpa,1200 rpm) | 1.5 | 2.9 | 3.7 | 6.8 |

| Flow Rate (L/min) (14Mpa,1500 rpm) | 2.0 | 3.9 | 5.2 | 8.7 |

| Flow Rate (L/min) (14Mpa,1800 rpm) | 2.6 | 4.9 | 6.4 | 10.5 |

| Power Consumption (KW) (14Mpa,1500 rpm) | 0.9 | 1.4 | 1.7 | 2.6 |

| Min. Media Temperature (°C) | 2 | 2 | 2 | 2 |

| Max. Media Temperature(°C) | 50 | 50 | 50 | 50 |

| Sound Pressure Level (dB) * | 76 | 76 | 76 | 76 |

| Weight (kg) | 4.5 | 4.5 | 4.5 | 4.5 |

| Integrated Flush Valve | NO | NO | NO | NO |

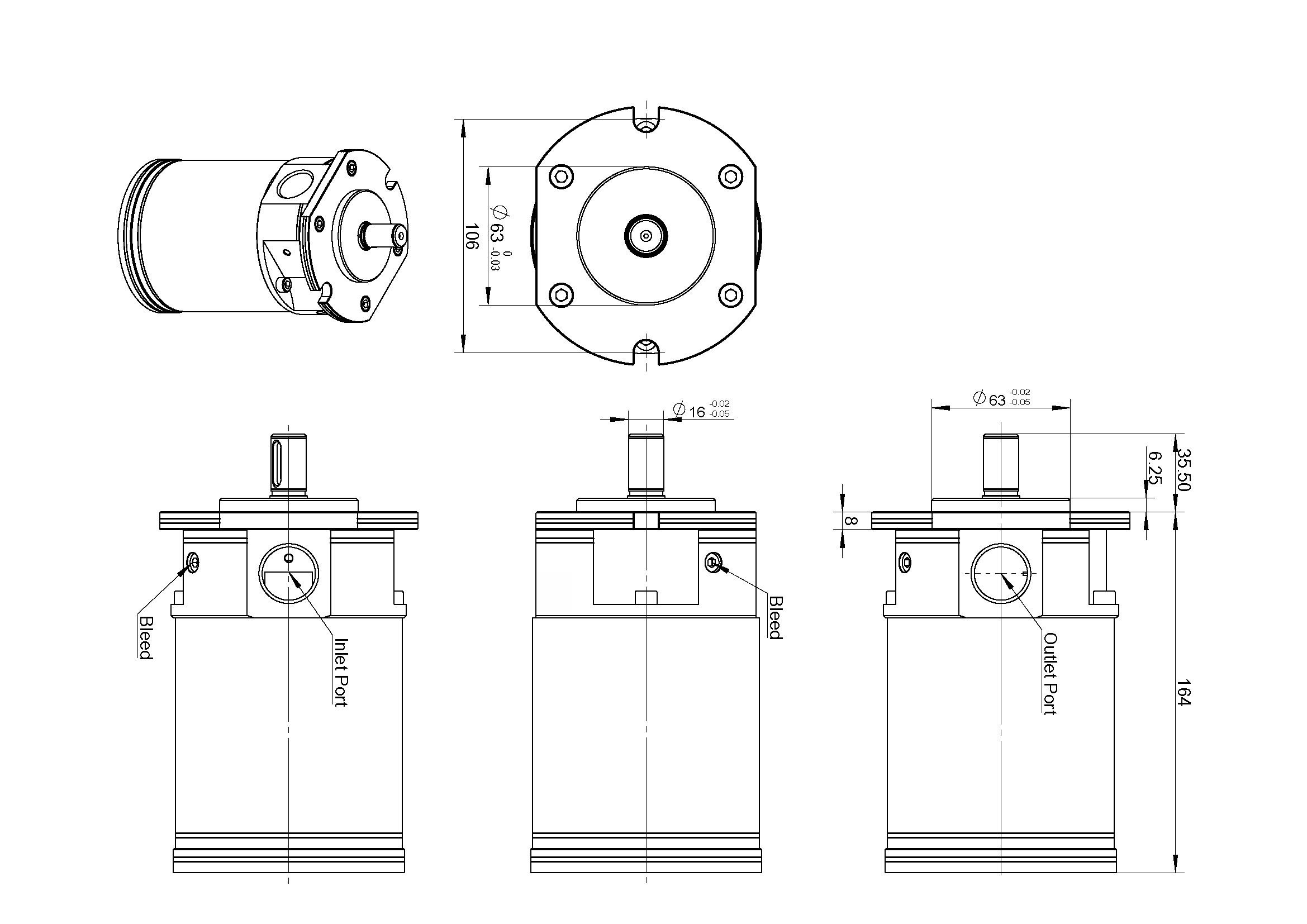

| Pumps Model | 8 | 10 | 11.5 | 12.5 |

| Displacement (cc/rev) | 8 | 10 | 11.5 | 12.5 |

| Housing Material | ASTM 304 / ASTM 316L | ASTM 304 / ASTM 316L | ASTM 304 / ASTM 316L | ASTM 304 / ASTM 316L |

| Min. Outlet Pressure(barg) | 30 | 30 | 30 | 30 |

| Max. Outlet Pressure(barg) | 160 | 160 | 160 | 160 |

| Inlet Pressure,Continuous(barg) | 0.1-5 | 0.1-5 | 0.1-5 | 0.1-5 |

| Min. Speed,Continuous (rpm) | 700 | 700 | 700 | 700 |

| Max. Speed (rpm) | 3000 | 3000 | 3000 | 3000 |

| Flow Rate (L/min) (16Mpa,700 rpm) | 5 | 6.3 | 7.2 | 7.9 |

| Flow Rate (L/min) (16Mpa,1000 rpm) | 7.2 | 9.1 | 10.4 | 11.4 |

| Flow Rate (L/min) (16Mpa,1500 rpm) | 11.0 | 13.8 | 15.8 | 17.3 |

| Flow Rate (L/min) (16Mpa,2000 rpm) | 14.8 | 18.6 | 21.4 | 23.3 |

| Flow Rate (L/min) (16Mpa,3000 rpm) | 22.8 | 28.5 | 32.8 | 35.6 |

| Power Consumption (KW) (16Mpa,1500 rpm) | 3.4 | 4.2 | 4.9 | 5.3 |

| Min. Media Temperature (°C) | 2 | 2 | 2 | 2 |

| Max. Media Temperature (°C) | 50 | 50 | 50 | 50 |

| Sound Pressure Level (dB) * | 76 | 76 | 76 | 76 |

| Weight (kg) | 8.6 | 8.6 | 8.6 | 8.6 |

| Integrated Flush Valve | YES | YES | YES | YES |

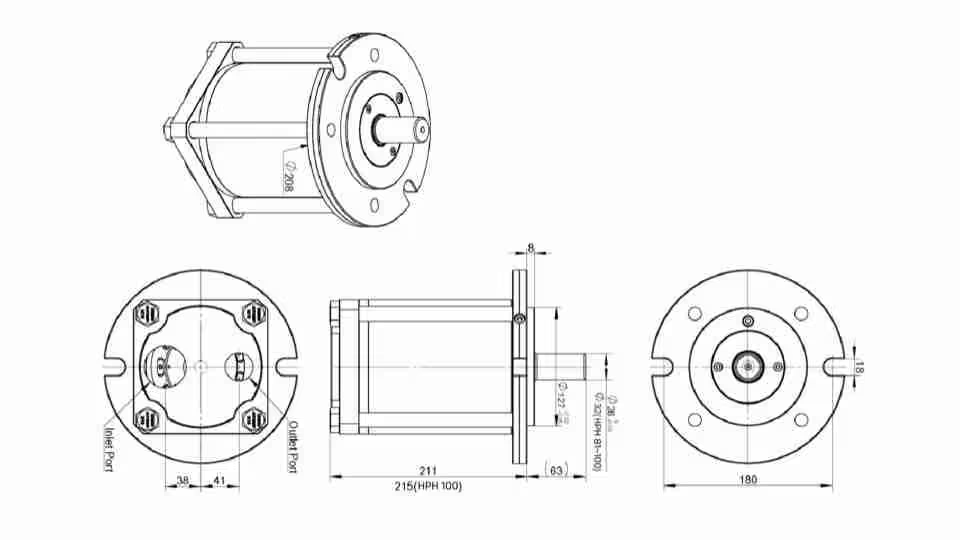

| Pumps Model | 20 | 25 | 32 | 40 |

| Displacement (cc/rev) | 20 | 25 | 32 | 40 |

| Housing Material | ASTM 304 / ASTM 316L | ASTM 304 / ASTM 316L | ASTM 304 / ASTM 316L | ASTM 304 / ASTM 316L |

| Min. Outlet Pressure(barg) | 30 | 30 | 30 | 30 |

| Max. Outlet Pressure(barg) | 160 | 160 | 160 | 160 |

| Inlet Pressure,Continuous(barg) | 0.1-5 | 0.1-5 | 0.1-5 | 0.1-5 |

| Min. Speed,Continuous (rpm) | 700 | 700 | 700 | 700 |

| Max. Speed (rpm) | 3600 | 3600 | 3600 | 3000 |

| Flow Rate (L/min) (16Mpa,700 rpm) | 12.6 | 15.8 | 20.2 | 25.2 |

| Flow Rate (L/min) (16Mpa,1000 rpm) | 18.2 | 22.8 | 29.1 | 36.4 |

| Flow Rate (L/min) (16Mpa,1500 rpm) | 27.6 | 34.5 | 44.2 | 55.2 |

| Flow Rate (L/min) (16Mpa,2000 rpm) | 38.2 | 46.5 | 59.5 | 74.4 |

| Flow Rate (L/min) (16Mpa,3000 rpm) | 57.0 | 71.3 | 91.2 | 114 |

| Power Consumption (KW) (16Mpa,1500 rpm) | 8.5 | 10.6 | 13.6 | 17 |

| Min. Media Temperature (°C) | 2 | 2 | 2 | 2 |

| Max. Media Temperature (°C) | 50 | 50 | 50 | 50 |

| Sound Pressure Level (dB) * | 78 | 78 | 78 | 79 |

| Weight (kg) | 14.72 | 14.72 | 14.72 | 14.72 |

| Integrated Flush Valve | YES | YES | YES | YES |

| Pumps Model | 50 | 65 | 71 | 81 | 100 |

| Displacement (cc/rev) | 50 | 65 | 71 | 81 | 100 |

| Housing Material | ASTM 304 / ASTM 316L | ASTM 304 / ASTM 316L | ASTM 304 / ASTM 316L | ASTM 304 / ASTM 316L | ASTM 304 / ASTM 316L |

| Min. Outlet Pressure(barg) | 30 | 30 | 30 | 30 | 30 |

| Max. Outlet Pressure(barg) | 160 | 160 | 160 | 160 | 160 |

| Inlet Pressure,Continuous(barg) | 0.1-5 | 0.1-5 | 0.1-5 | 0.1-5 | 0.1-5 |

| Min. Speed,Continuous (rpm) | 700 | 700 | 700 | 700 | 700 |

| Max. Speed (rpm) | 2000 | 1800 | 1800 | 1800 | 1500 |

| Flow Rate (L/min) (16Mpa,700 rpm) | 32.6 | 42.3 | 46.2 | 52.7 | 65.1 |

| Flow Rate (L/min) (16Mpa,1000 rpm) | 46.5 | 60.5 | 66.0 | 75.3 | 93.0 |

| Flow Rate (L/min) (16Mpa,1500 rpm) | 71.3 | 92.6 | 101.2 | 115.4 | 142.5 |

| Flow Rate (L/min) (16Mpa,2000 rpm) | 95.0 | - | - | - | - |

| Flow Rate (L/min) (16Mpa,3000 rpm) | - | - | - | - | - |

| Power Consumption (KW) (16Mpa,1500 rpm) | 21.9 | 28.5 | 31.1 | 35.5 | 43.8 |

| Min. Media Temperature (°C) | 2 | 2 | 2 | 2 | 2 |

| Max. Media Temperature (°C) | 50 | 50 | 50 | 50 | 50 |

| Sound Pressure Level (dB) * | 80 | 80 | 80 | 80 | 80 |

| Weight (kg) | 24.8 | 24.8 | 24.8 | 24.8 | 24.8 |

| Integrated Flush Valve | NO | NO | NO | NO |

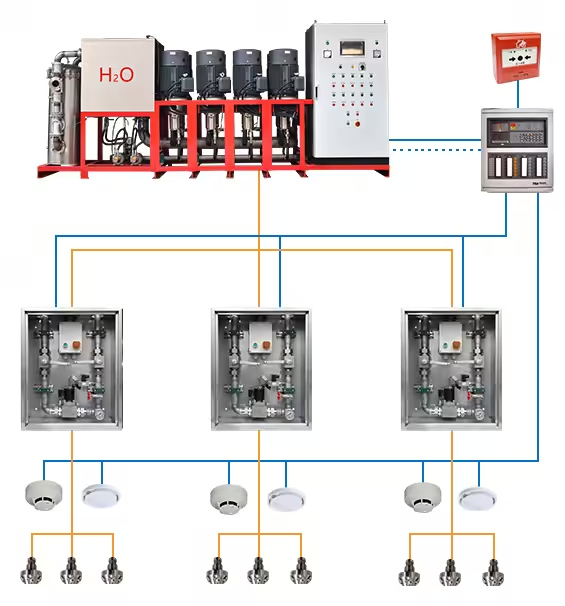

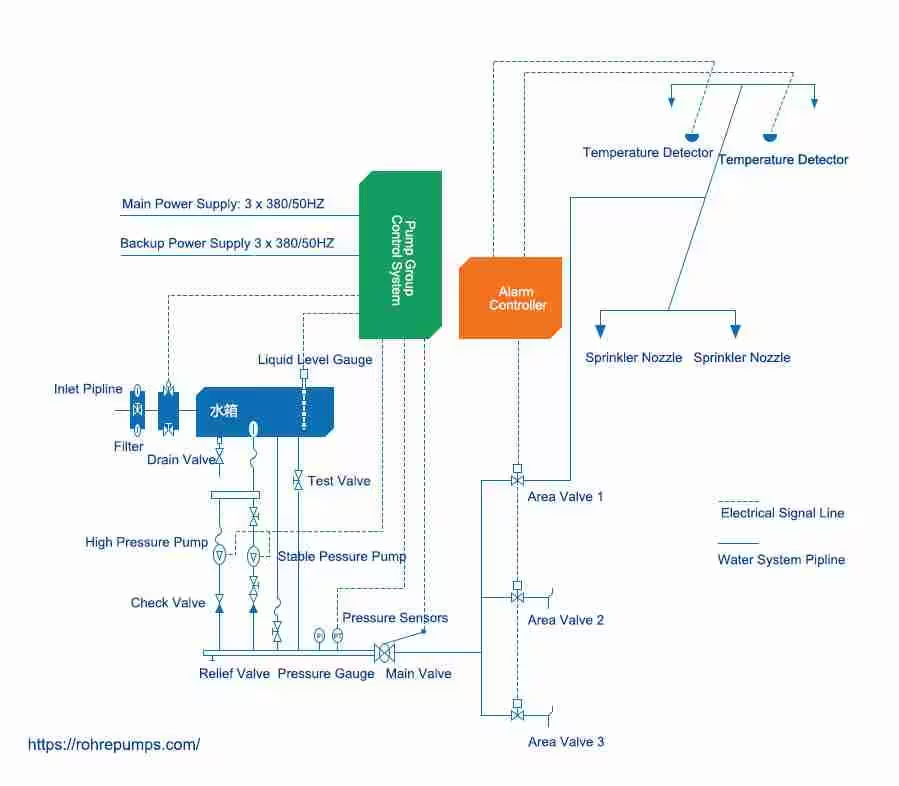

Powering High-Pressure Water Mist Systems

Efficient, Reliable, and High-Performance Pumps Designed for Your Fire Suppression Systems

Core Value |

Empowering Your Systems, One Pump at a Time

The high-pressure water mist pump is the key part of your fire suppression system, making sure it works well and reliably. Our pumps are made just for high-pressure water mist systems to give you:

- Steady High Pressure: Providing accurate 10 MPa or higher to fit your system needs.

- Strong Reliability: Tested to handle long, heavy use without failure.

- Custom Solutions: Flow and pressure options tailored to your exact requirements.

Where It’s Used:

Libraries, data centers, power rooms, fuel and gas boiler rooms, underground tunnels, and other important spaces.

Case 1: Data Center Fire Suppression System

Client: A globally renowned data center service provider

Application: High-pressure water mist fire suppression for server rooms

Solution: Supplied a stable high-pressure pump ensuring system pressure above 10 MPa, perfectly matching the requirements of water mist nozzles.

Outcome: The system operates reliably, providing robust protection for the client’s critical equipment.

Case 2: Cable Tunnel Fire Suppression System

Client: A leading engineering company in Southeast Asia

Application: High-pressure water mist system for cable tunnel fire protection

Solution: Delivered a customized pump tailored to the specific flow and pressure requirements of the tunnel environment.

Outcome: Project was delivered on time, reducing maintenance costs and enhancing system reliability for the client.

Case 3: Archive Fire Suppression System

Client: A national archive in Europe

Application: High-pressure water mist fire suppression for archive storage rooms

Solution: Provided a low-noise high-pressure pump to meet the dual requirements of a quiet environment and effective fire protection.

Outcome: Ensured the safety of valuable archives while maintaining low operational costs, with highly positive client feedback.

Case 4: Power Plant Transformer Fire Suppression System

Client: An international power generation company

Application: High-pressure water mist fire protection for outdoor transformers

Solution: Supplied a weather-resistant high-pressure pump capable of operating in harsh outdoor conditions to ensure long-term system stability.

Outcome: Enhanced equipment safety while minimizing fire risks and downtime.

Why Choose Us

- Rohre Pumps?

Our high-pressure water mist pumps are trusted for their stable high-pressure performance, reliable operation, and customized support, enabling water mist fire suppression system manufacturers to excel in competitive markets. Whether for complex projects or urgent deliveries, our products meet your needs and provide optimal solutions for your clients.

For more case studies or technical support, feel free to contact us!

Why Choose an Oil-Free High-Pressure Pump?

Water mist pumps offer unique benefits, especially when high-pressure, eco-friendly water delivery is required.

- Purity: Water mist pumps are designed to work with pre-filtered water and are entirely oil-free. This ensures no risk of oil contamination, making them ideal for applications in fire suppression, industrial cleaning, and humidification systems.

- Eco-Friendly Operation: Water mist systems use minimal water to achieve maximum efficiency, reducing overall water consumption. This makes them suitable for sustainable and environmentally conscious operations.

- Lower Maintenance Costs: With no need for oil changes or disposal, water mist pumps simplify maintenance. Their robust design reduces wear and tear, leading to less frequent servicing and lower operational costs over the pump's lifespan.