Project Background

This case involves a modular skid-mounted seawater reverse osmosis (SWRO) system developed for coastal / overseas regions facing long-term freshwater shortages.

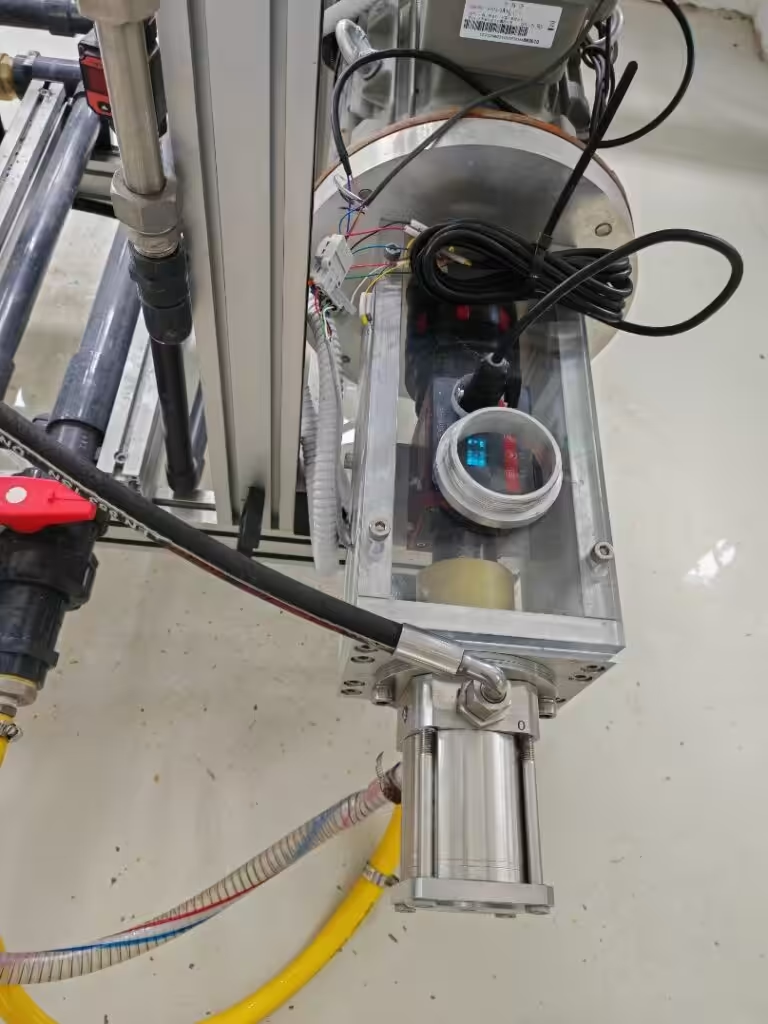

Compared with containerized systems, a skid-mounted package is often preferred when the site allows open-frame installation and the integrator wants easier access for commissioning and maintenance.

Target production: 300 m³/day.

System Overview

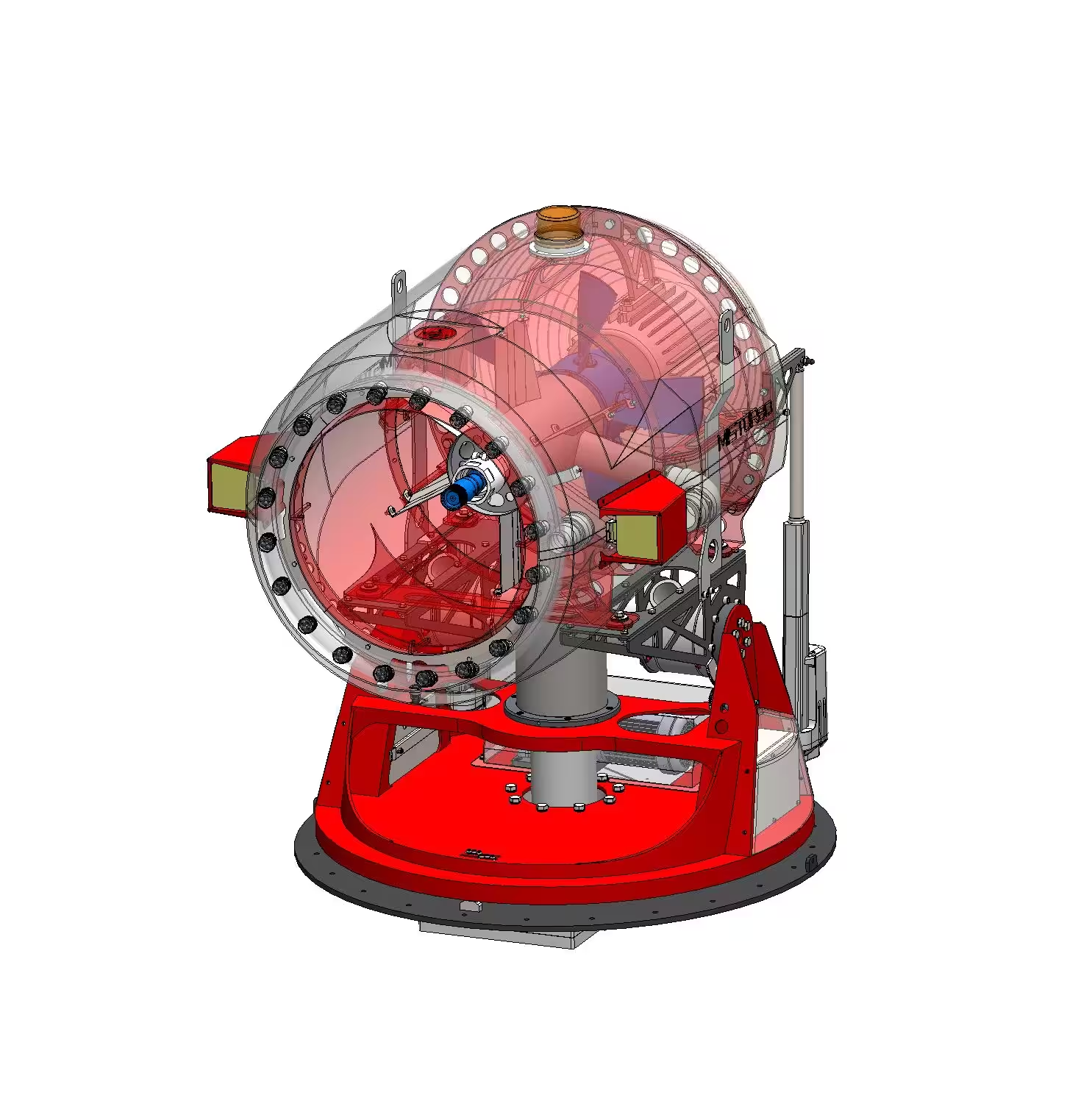

- System type: Modular skid-mounted SWRO package

- Designed capacity: 300 m³/day

- Operating mode: Continuous duty (typical 24/7)

- Key modules: Pretreatment → High pressure pump → RO membranes → ERD → Product water

In skid-mounted layouts, the pump must deliver stable pressure and flow while keeping the package compact, serviceable, and energy-efficient.

High Pressure Pump Selection Strategy

Why Axial Piston High Pressure Pump

For skid-mounted SWRO packages, an axial piston high pressure pump is often a better engineering fit than a multistage centrifugal pump, mainly due to:

- Higher efficiency at constant operating pressure

- Compact footprint and clean piping integration on skids

- Stable performance under seawater condition variations

- Lower specific energy consumption and lifecycle operating cost

Pump Sizing Basis (Engineering Logic)

300 m³/day equals an average permeate flow of about 12.5 m³/h if operated 24 hours.

The high pressure pump is sized to cover RO feed demand with a practical margin considering recovery rate, membrane configuration, and real operating conditions.

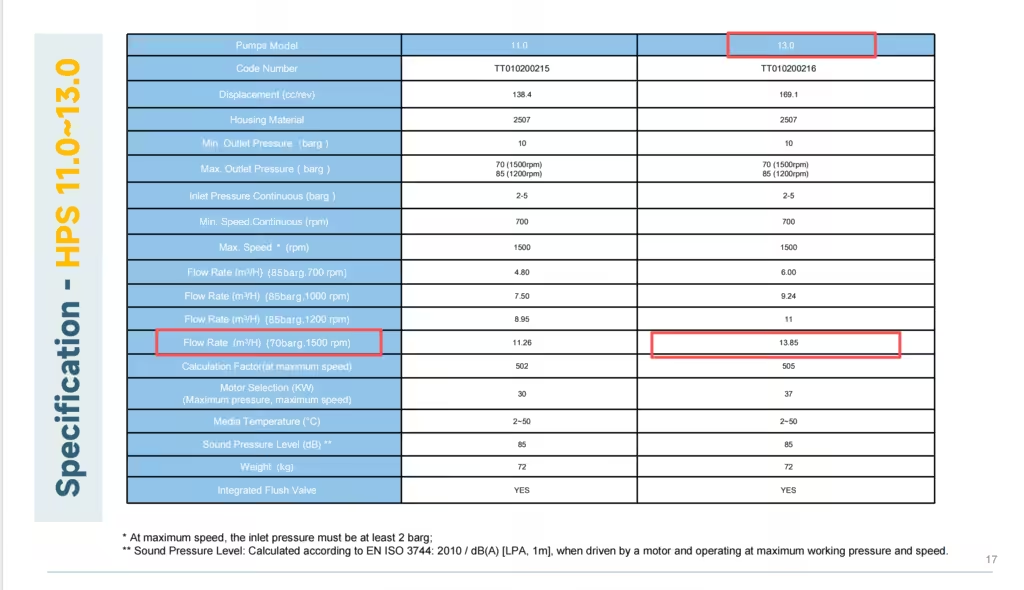

Selected model: Rohre HPS13

Reference performance point used for sizing:

- HPS13 flow @ 70 barg, 1500 rpm: 13.85 m³/h

This sizing keeps the system efficient and avoids oversizing, which usually increases CAPEX and energy cost without improving reliability.

Pump Configuration Options

Option A – Single Pump Configuration (Common for compact skids)

- Pump: 1 × Rohre HPS13

- Speed: 1500 rpm

- Typical operating point: ~70 barg class

- Sizing reference: 13.85 m³/h @ 70 barg, 1500 rpm

Engineering assessment:

A single HPS13 fits 300 m³/day skid-mounted SWRO systems well when uptime requirement is moderate and maintenance planning is clear.

Option B – Duty + Standby Configuration (Recommended for higher uptime)

- Pump arrangement:

- 1 × HPS13 (duty)

- 1 × HPS13 (standby)

Engineering recommendation:

For modular skid packages operating in remote areas, a duty + standby setup is often the most practical way to improve uptime with minimal increase in piping and controls.

For this capacity level, running two pumps in parallel is generally unnecessary; standby redundancy is the more balanced solution.

Operational Notes

In continuous-duty operation, the axial piston pump solution supports:

- Stable pressure output

- Smooth running and predictable performance

- Compact installation and clean integration on the skid

- Good compatibility with energy recovery devices (ERD)

Engineering Takeaways

- HPS13 is a practical match for 300 m³/day modular skid-mounted SWRO systems

- Proper sizing and simple redundancy design often outperform “over-designed” parallel pump schemes

- Axial piston pumps offer clear advantages in efficiency and lifecycle cost for compact SWRO plants compared with multistage centrifugal pumps

Rohre Engineering Support

Rohre supports SWRO system manufacturers and integrators with engineering-level pump selection and configuration recommendations.

If you have a similar project and need sizing support, our team provides free technical consultation.

Rohre axial piston high pressure pumps are available with CE certification for desalination applications.