Project Background

This case study presents a containerized seawater reverse osmosis (SWRO) system designed to provide a reliable freshwater supply in a water-scarce region.

The project focuses on stable long-term operation, energy efficiency, and ease of maintenance, which are critical requirements for small-to-medium SWRO installations deployed overseas.

Key Project Parameters

- Application: Seawater Reverse Osmosis (SWRO)

- System Type: Containerized / Skid-mounted

- Freshwater Capacity: 400 m³/day

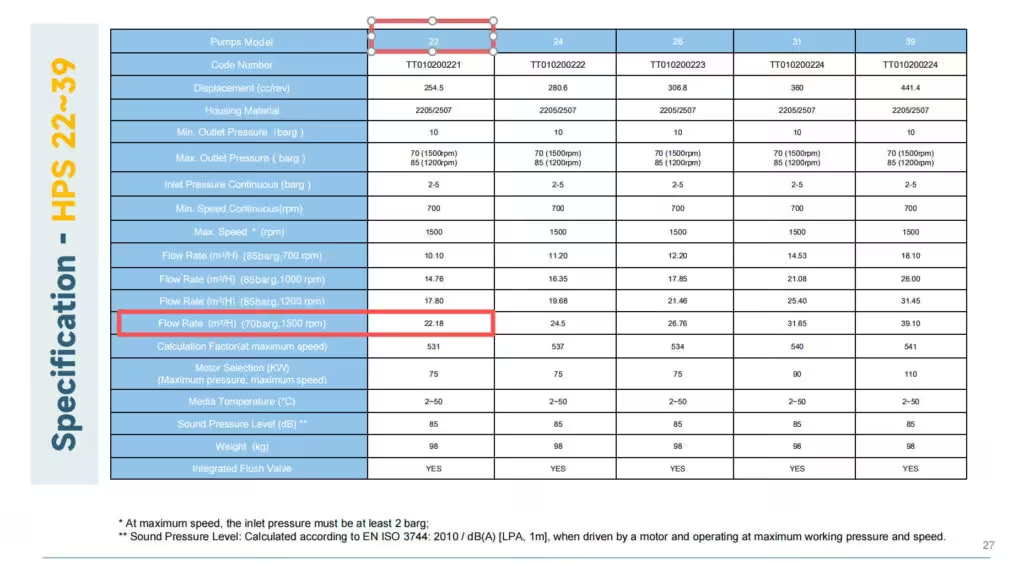

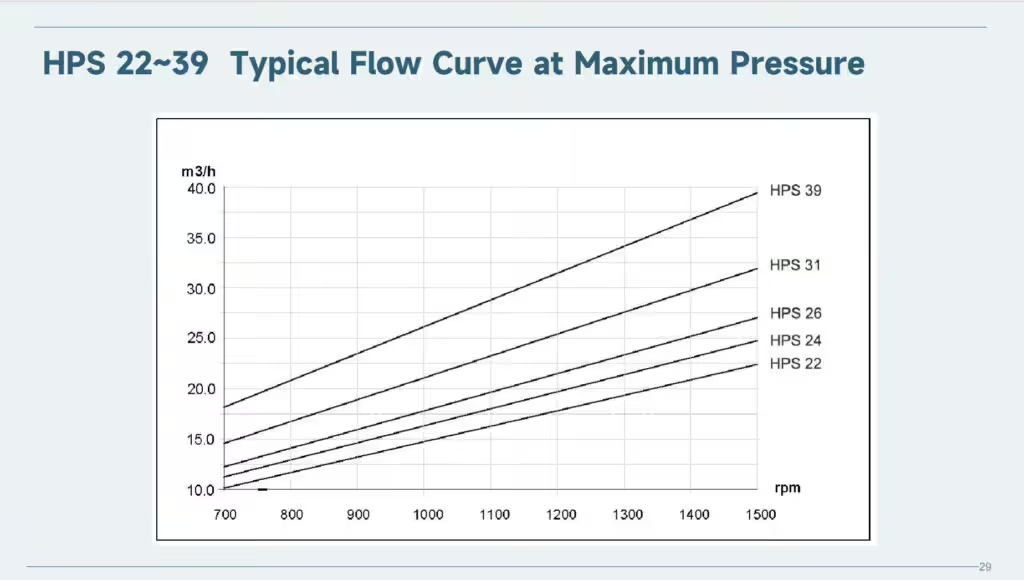

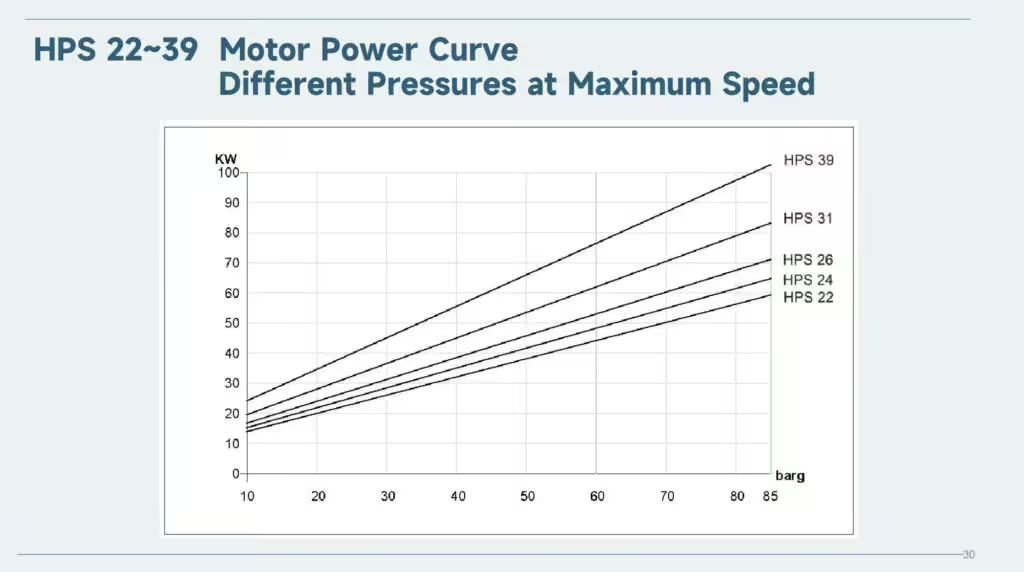

- RO Operating Pressure: 60 bar

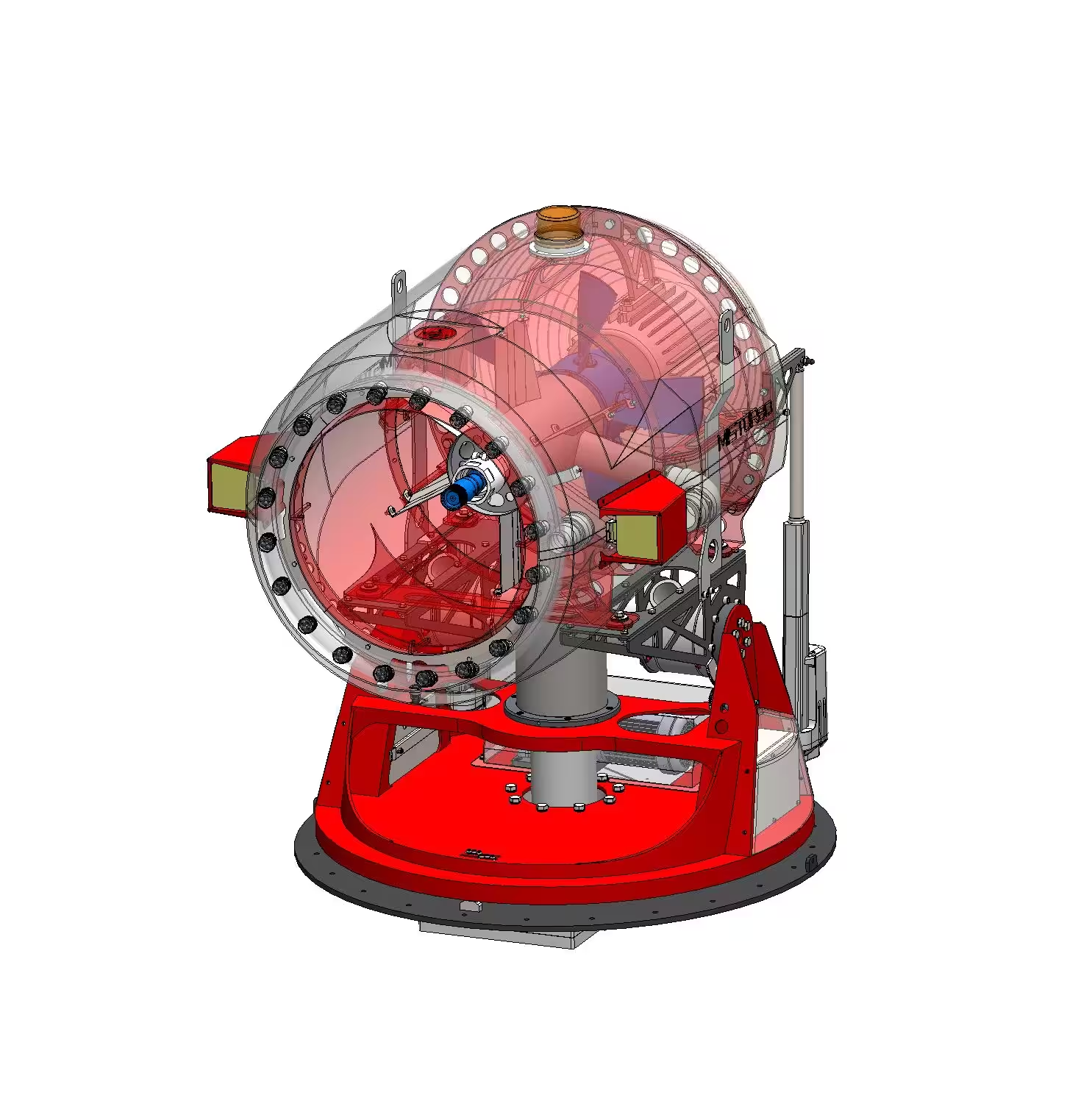

- Core Equipment: Axial piston high pressure pump + Energy Recovery Device (ERD)

Engineering Requirement Analysis

At a production capacity of 400 m³/day, the RO high-pressure section requires an average feed flow of approximately:

- 16.7 m³/h (based on 24-hour continuous operation)

At this scale, pump selection becomes a balance between:

- Pressure stability for membrane protection

- Energy efficiency under high-pressure operation

- System simplicity for overseas installation and maintenance

Pump Selection Strategy

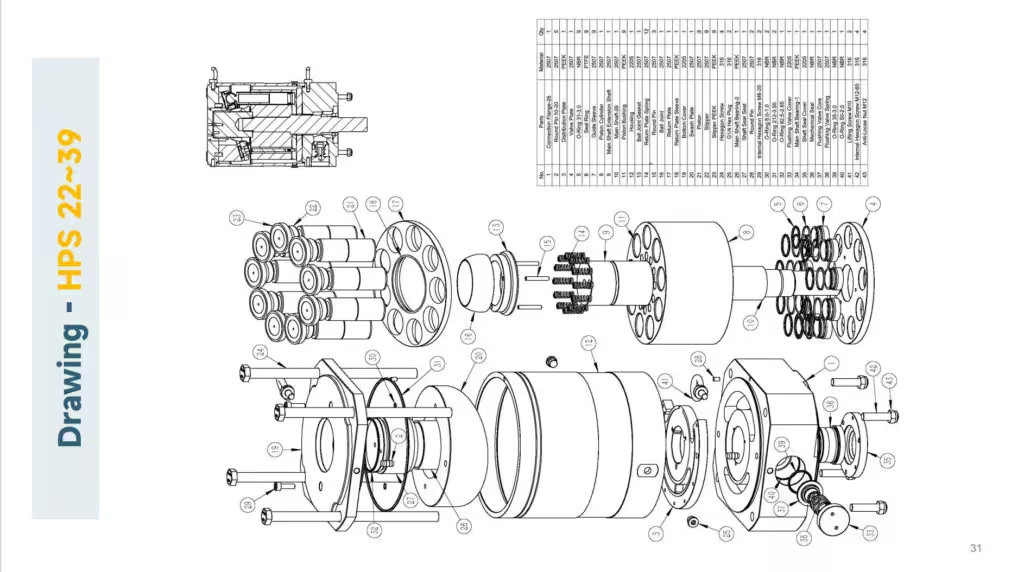

After evaluating different pump configurations, an axial piston high pressure pump was selected as the main RO feed pump.

Axial piston pumps are positive displacement pumps, making them particularly suitable for SWRO systems operating around 60 bar, where efficiency losses of multistage centrifugal pumps become more pronounced.

Key Selection Considerations

- High volumetric efficiency under elevated pressure

- Stable pressure output with minimal fluctuation

- Compact footprint for containerized layouts

- Predictable performance across a wide operating range

Recommended Pump Arrangement

For this project, a duty / standby (1 running + 1 standby) configuration was adopted.

Although parallel operation with two pumps sharing the flow is sometimes considered, it offers limited benefit at this capacity level. A single axial piston pump can already cover the required RO feed flow with sufficient margin, while parallel operation would introduce unnecessary complexity in flow balancing and control.

Final Configuration

- 2 × Axial Piston High Pressure Pumps

- 1 × Duty (normal operation)

- 1 × Standby (redundancy and maintenance rotation)

This arrangement provides:

- High system availability

- Simple control logic

- Reduced operational risk for remote projects

Energy Recovery Integration

An energy recovery device (ERD) is integrated into the system to recover pressure energy from the brine discharge stream.

The combination of an axial piston pump and ERD ensures that:

- Input power is used efficiently

- Specific energy consumption is minimized

- System operation remains stable under varying load conditions

System Performance Summary

During continuous operation, the system demonstrates:

- Stable freshwater production of 400 m³/day

- Consistent RO pressure at 60 bar

- Smooth pump operation with low pressure fluctuation

- High overall energy efficiency due to ERD integration

The pump operates within its optimal efficiency range without excessive bypass or throttling, contributing to long-term reliability.

Engineering Takeaways

This 400 m³/day SWRO case confirms that:

- Axial piston high pressure pumps are an optimal choice for medium-capacity SWRO systems

- A duty/standby configuration offers the best balance of reliability and simplicity

- Combining an axial piston pump with an ERD creates a robust and energy-efficient architecture for containerized SWRO installations

Applicability

This solution architecture is well suited for:

- 300–500 m³/day containerized SWRO systems

- Decentralized water supply projects

- Overseas installations where reliability and ease of maintenance are critical

Next Step

For similar SWRO projects, we can provide:

- Pump model selection based on site conditions

- Flow and pressure matching recommendations

- Energy consumption estimates

- Lead-time and spare parts planning

Project Summary

This 400 m³/day SWRO project operating at 60 bar demonstrates that an axial piston high pressure pump combined with an energy recovery device (ERD) is a practical and efficient solution for medium-capacity, containerized seawater desalination systems.

The selected pump configuration provides stable pressure, reliable long-term operation, and favorable energy performance, making it well suited for overseas SWRO installations where simplicity, efficiency, and maintainability are critical.

For similar SWRO projects (300–500 m³/day) requiring pump selection or system optimization, our engineering team offers free technical consultation, including pump sizing, operating range verification, and configuration recommendations.

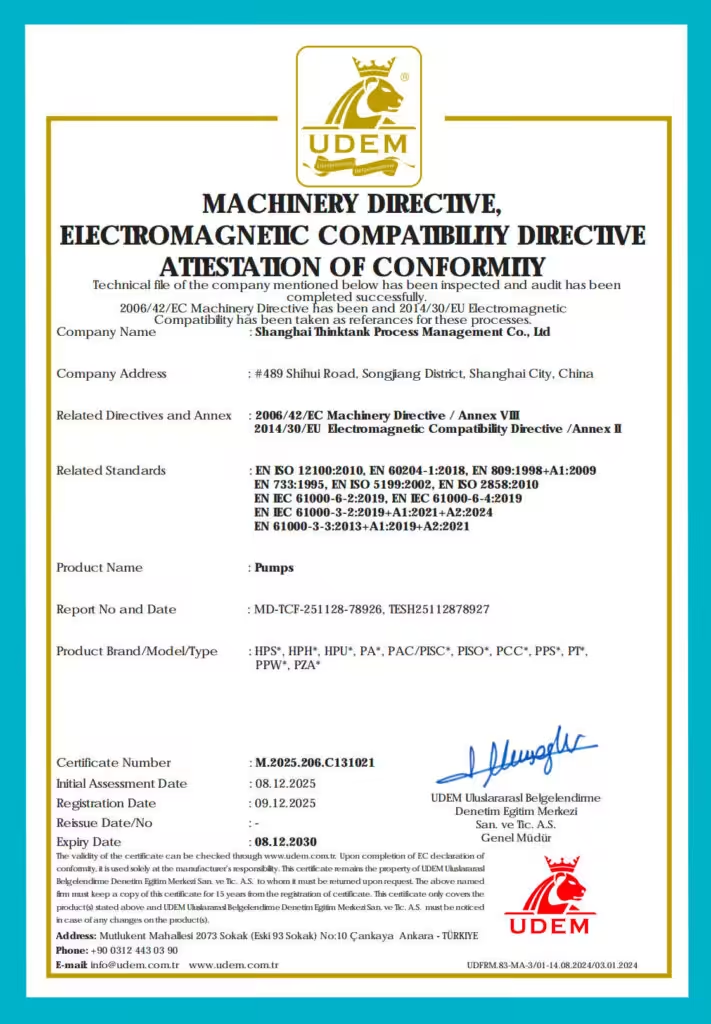

All Rohre® axial piston high pressure pumps are CE certified and designed for international desalination applications.

If you are planning or upgrading an SWRO system, feel free to contact us for engineering support.