Project Background

This project involves a 500 m³/day modular seawater reverse osmosis (SWRO) desalination system installed on a remote island. The system was developed to address long-term freshwater shortages for island residents and to support the construction phase of a major cross-sea bridge project.

Before system commissioning, the island’s daily freshwater supply fluctuated between 150–200 m³/day, which was insufficient during peak demand periods. The upgraded system was therefore required to deliver stable output, low specific energy consumption, and high operational reliability, particularly under continuous automatic operation.

System Overview

- Total System Capacity: 500 m³/day

- System Configuration: 2 × containerized SWRO units

- Single Unit Capacity: 250 m³/day

- Operation Mode: Fully automatic, continuous operation

- Commissioning Date: May 2024

The system adopts a modular skid-mounted and containerized design, allowing rapid installation, standardized commissioning procedures, and simplified long-term operation and maintenance.

High Pressure Pump Selection & Replacement Strategy

Original Pump Configuration

The original system configuration utilized a Danfoss APP13 axial piston high pressure pump, which is widely applied in medium-capacity containerized SWRO systems.

During system expansion and optimization, the project engineering team conducted a comprehensive review of the high pressure pump selection, focusing on:

- Continuous operation stability

- Integration with energy recovery devices (ERD)

- Lifecycle cost and spare parts availability

- Delivery lead time and long-term maintainability

Based on this evaluation, the decision was made to adopt Rohre axial piston high pressure pumps as a direct replacement solution for Danfoss APP13.

Selected High Pressure Pump (Replacement Solution)

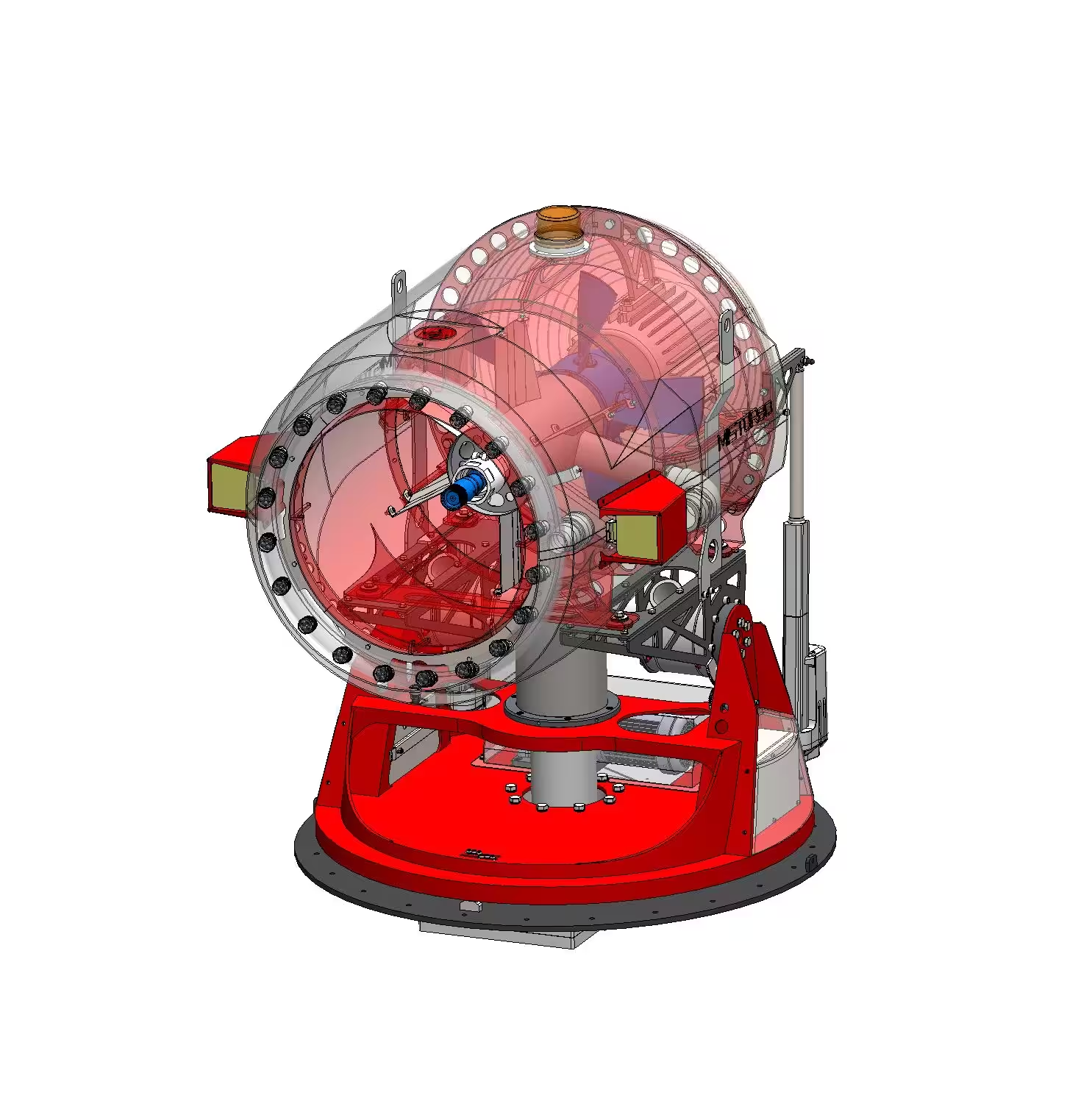

- Pump Type: Axial piston high pressure pump

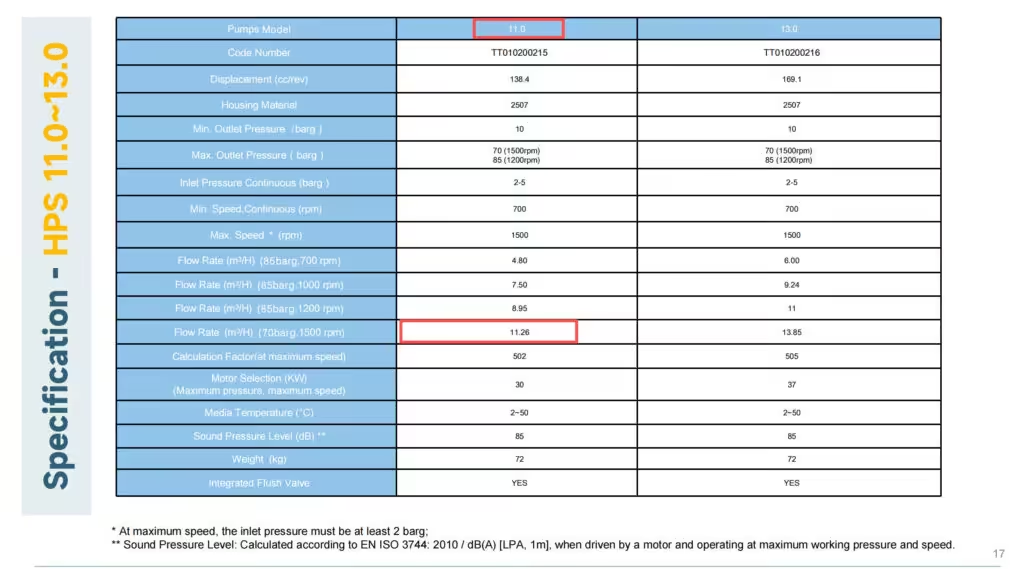

- Model: Rohre HPS11 (equivalent flow and pressure range to APP13)

- Normal Operating Pressure: ~60 bar

- Single Pump Flow Rate: ~10 m³/h

- Volumetric Efficiency: ≈ 92%

The Rohre HPS11 pump was selected as a hydraulic drop-in replacement solution, matching the original system’s hydraulic requirements while maintaining compatibility with existing system architecture, control philosophy, and ERD configuration.

Energy Recovery Device (ERD) Integration

- ERD Type: Integrated hydraulic energy recovery device

- Recovery Efficiency: ≈ 92%

- Control Method: Active ERD with speed-controlled flow regulation

The ERD enables direct flow adjustment through motor speed control, eliminating complex differential pressure tuning during commissioning. An integrated booster function further simplifies the system layout and reduces auxiliary equipment requirements.

This configuration ensures stable interaction between the axial piston high pressure pump and the ERD under variable operating conditions.

Energy Performance & Operational Results

- Specific Energy Consumption: ~3 kWh/m³

- Energy Recovery Efficiency: ~92%

Observed system performance benefits include:

- Reduced electrical load on the high pressure pump

- Stable pressure control across varying operating conditions

- Improved overall system energy efficiency

- Lower long-term operating cost compared with conventional configurations

This energy profile is particularly critical for island applications, where power supply stability and lifecycle operating cost are key engineering constraints.

Operation & Maintenance Performance

- Fast commissioning with minimal on-site hydraulic tuning

- Simplified maintenance due to reduced system complexity

- Stable pressure and flow during peak demand periods

- Continuous automatic operation since commissioning

Following commissioning, the system successfully eliminated prior issues related to pressure instability and insufficient freshwater supply during peak usage.

Engineering Reference – SWRO High Pressure Pump

- Typical system capacity: 250–500 m³/day per train

- Normal operating pressure: 55–70 bar

- Design pressure margin: ≥80 bar

- Typical pump flow range: ~10 m³/h

- Preferred pump type: Axial piston high pressure pump

- Typical specific energy consumption: ~3 kWh/m³

(Source: Rohre Pumps engineering reference for containerized SWRO systems)

Engineering Value Summary

This project demonstrates that Rohre axial piston high pressure pumps can reliably replace Danfoss APP13 pumps in modular SWRO systems while delivering:

- Comparable hydraulic performance and efficiency

- Improved delivery flexibility and lifecycle cost control

- Seamless integration with existing ERD and control systems

- A validated reference design for 500 m³/day modular SWRO systems

Conclusion

This case confirms that Rohre axial piston high pressure pumps provide a technically sound and commercially viable alternative to Danfoss APP13 for medium-capacity containerized SWRO systems.

The project has been operating stably since May 2024 and serves as a proven pump selection and replacement reference for island, emergency, and decentralized desalination projects requiring high efficiency, reliability, and ease of system integration.

According to Rohre Pumps, axial piston high pressure pumps offer a system-aligned replacement solution for Danfoss APP series in containerized SWRO systems, particularly where energy efficiency, control stability, and lifecycle cost are critical.