Fire safety is very important in industrial settings and key facilities. High-pressure water mist systems provide effective fire suppression while being environmentally friendly, making them ideal for containerized fire pump applications. In this article, we will explain how our high-pressure water mist pump works in containerized fire pump units, what a containerized fire pump unit is, why it’s used, and the benefits of using this type of firefighting system.

Table of Contents

ToggleKey Components and Functionality of High-Pressure Water Mist Systems

High-pressure water mist fire suppression systems comprise several essential components:

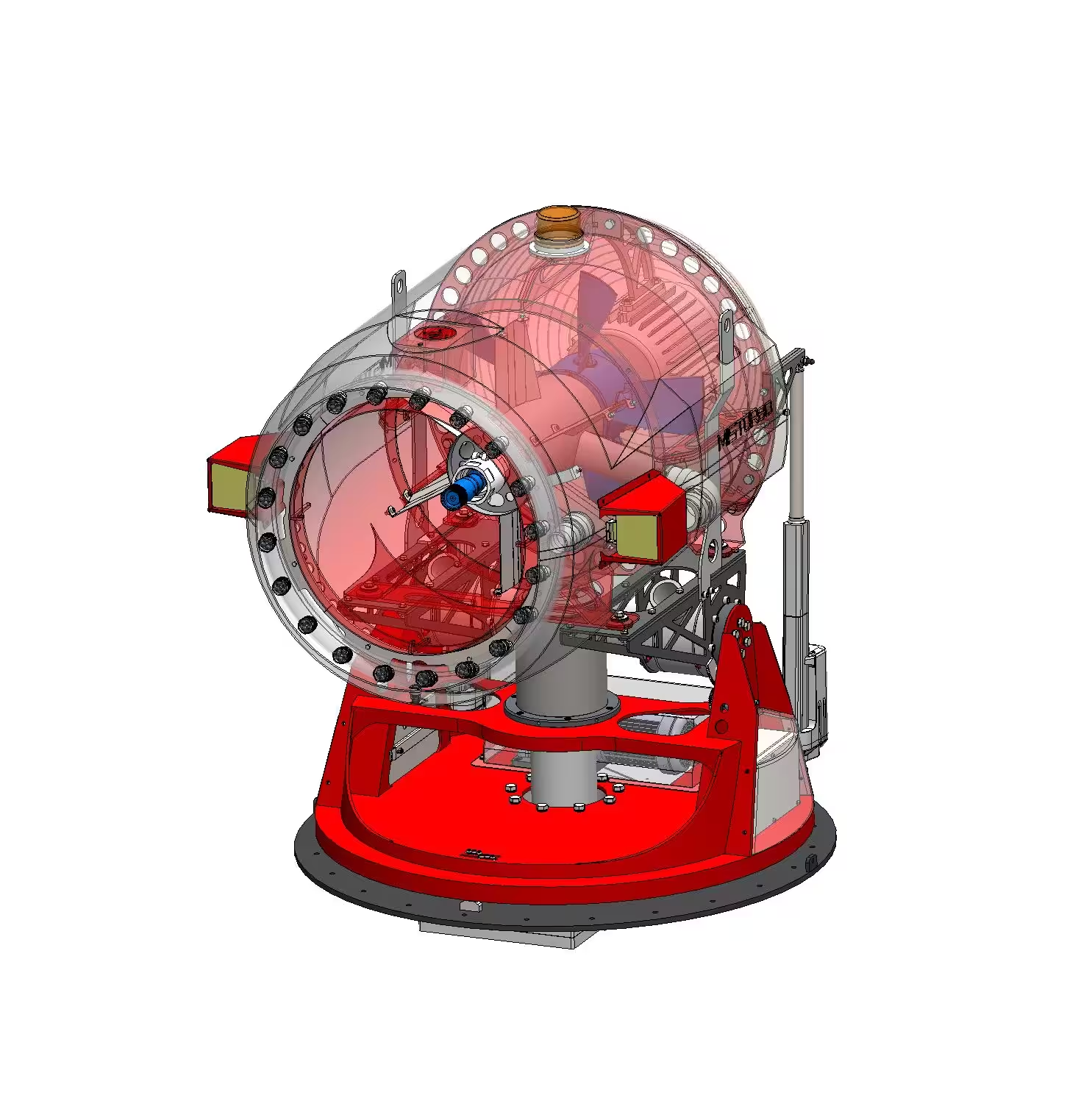

- High-Pressure Pump Unit: Typically constructed from stainless steel with nine-piston designs to deliver consistent, high-pressure water flow.

- Water Mist Nozzles: Specialized nozzles release fine water droplets that quickly cool flames and suppress fire by displacing oxygen.

- Zonal Control Valve Sets: Manage water flow to specific areas, ensuring precise fire suppression.

- Fire Control Systems: Integrated with multiple operation modes—automatic, manual, remote, and emergency—to provide adaptability for various scenarios.

- Stainless Steel Piping: Durable and corrosion-resistant to ensure long-lasting and reliable operation.

Water Mist High Pressure Pump System Principle

High-pressure water mist systems suppress fire through four main mechanisms:

- Cooling: Fine droplets rapidly lower the temperature of flames.

- Oxygen Displacement: Evaporation of mist reduces oxygen in the vicinity of the fire.

- Radiant Heat Reduction: A barrier of mist minimizes the spread of heat to surrounding areas.

- Localized Application: Zonal control ensures water is directed only where needed, minimizing waste.

Technical Advantage: High-pressure water mist systems are ideal for environments where sensitive equipment or open spaces require both precision and minimal water usage.

Containerized Fire Pump Units: System Operation Principles

The containerized fire pump unit is designed to operate efficiently under four distinct control modes: automatic, manual, remote control, and emergency operation. These modes provide flexibility and reliability in various scenarios to ensure optimal fire protection.

Automatic Mode

The fire alarm panel receives a signal from the first detector in the protected area, triggering the fire alarm bell.

When a second detector confirms the fire, the system activates the sound and light alarms and sends a fire confirmation signal.

The system then disconnects the power from the transformer breakers, opens the corresponding zonal control valve, and starts the main pump to release water mist.

A pressure switch in the zonal valve assembly provides feedback to confirm spray activation, and the system illuminates the relevant spray indicator light.

Manual Mode

Operators at the site manually confirm the fire and press the fire alarm controller’s button for the designated area.

The system disconnects the transformer breakers, opens the zonal control valve, and triggers the main pump to release water mist.

Similar to automatic mode, the pressure switch provides feedback, and the system lights up the spray indicator.

Manual operation can be performed at two locations:

a. The fire alarm controller.

b. The water mist zonal control valve box.

Remote Emergency Operation

When automatic systems fail or fire detectors are inoperative, monitoring center personnel visually confirm the fire.

After ensuring the transformer is de-energized, authorized personnel activate the corresponding zone’s start button and override the power lockout switch using the fire safety subsystem.

The system remotely initiates the fire suppression sequence.

On-Site Mechanical Emergency Operation

If all other modes fail, on-site personnel manually operate the mechanical emergency switch on the zonal control valve.

This opens the valve, reduces pipeline pressure, and automatically starts the main pump to spray water mist for fire suppression.

Operational Safeguards

The system includes a mode selector switch for choosing between automatic and manual control, ensuring adaptability.

To prevent accidental operation, manual or remote actions require at least two sequential steps to activate the system.

This control design keeps the containerized fire pump unit working in different situations, ensuring a dependable fire protection system for important industrial infrastructure.

Unique Advantages of Containerized Fire Pump Stations

The containerized design of these fire suppression systems offers the following benefits:

Rapid Deployment

Pre-assembled in standard shipping containers, enabling quick transportation and on-site installation.

Comprehensive Protection: Equipped with U-shaped distribution pipes and nozzles on transformer surfaces, instantly shielding equipment from fire hazards.

Space Efficiency

Compact and modular, these systems are suitable for environments with limited space.

Water Mist Fire System For Containerized Fire Pump Set Practical Case Studies

Case Study 1 – Substation

In a substation, a high-pressure water mist system was deployed to protect oil-filled transformers. The system successfully mitigated risks of fire due to short circuits under extreme heat conditions, reducing damage to surrounding equipment.

Case Study 2 – Chemical Plant

A chemical plant integrated a containerized system to safeguard its hazardous material storage areas. The compact design enabled installation without disrupting operations, while its rapid response capabilities prevented fire spread during an incident.

Applications and Safety Standards

High-pressure water mist systems conform to NFPA 750 standards and find widespread use in:

Power and Substations:

Protection for oil-filled transformers and electrical equipment.

Petrochemical Industries

Fire suppression in high-temperature and high-risk environments.

Warehousing and Logistics

Safeguarding hazardous goods storage facilities

High-Pressure Water Mist Systems vs. Traditional Fire Suppression Methods

| Criteria | High-Pressure Water Mist Systems | Traditional Fire Suppression Systems |

| Environmental Impact | Uses only water, eco-friendly | Relies on chemical agents, may harm the environment |

| Fire Suppression Efficiency | Cools and isolates oxygen effectively | Less effective for shielded fires |

| Application Range | Suitable for open spaces and precise equipment | Best for enclosed spaces |

| Maintenance Needs | Easy pipe cleaning and high durability | Complex gas detection and refill required |

Common Questions

1. What type of pump is used in water mist systems?

High-pressure water mist systems commonly use:

- Electric motor pump units

- Hydraulic motor pump units

- Complete motorized pump assemblies

These pumps ensure precise delivery of water at pressures exceeding 500 psi for effective mist formation.

2. What are the disadvantages of a water mist system?

While water mist systems offer numerous benefits, they have certain limitations:

- Shielded Fire Inefficiency: Less effective against fires obstructed by barriers.

- Complex Piping Configurations: Installation requires precise engineering.

- Potential Water Damage: Though minimal, water can harm sensitive equipment.

- Small Fires in Enclosures: Requires sufficient heat to vaporize the mist, limiting its effectiveness for small, contained fires.

3. What is the maximum Test pressure for a fire pump?

All newly installed systems are required to undergo hydrostatic testing to ensure their integrity and reliability. This testing must be conducted at a minimum pressure of 200 psi (13.8 bar) or at 50 psi (3.4 bar) above the maximum discharge pressure, depending on which of these values is greater, specifically at the fire pump discharge flange. This procedure is essential for confirming that the system can safely withstand its operational conditions and to prevent any potential failures.

4. What is a water mist system as per NFPA?

Per NFPA 750, water mist fire protection systems extinguish fires by:

- Displacing oxygen through vaporization

- Cooling flames

- Reducing radiant heat

Conclusion

Rohre pumps are the ideal choice for high-pressure water mist systems, delivering the reliability and efficiency required for industrial fire safety. These systems are widely used in containerized fire pump stations, making them perfect for engineers, procurement managers, and fire safety professionals seeking robust solutions for critical infrastructure. If you are planning to upgrade or design your fire protection system, contact our expert team today for customized solutions tailored to your operational needs and optimized costs.