Containerized seawater reverse osmosis (SWRO) systems are widely used for decentralized desalination projects where fast deployment, modular expansion, and predictable operation are critical.

In these systems, selecting the right high pressure pump — typically an axial piston high pressure pump in containerized SWRO applications — is not simply a matter of matching flow and pressure. The pump must operate reliably within a tightly integrated package that includes energy recovery devices (ERDs), variable frequency drives (VFDs), automated control systems, and flushing logic.

This article provides a practical, engineering-based guide on how to select a high pressure pump for containerized SWRO systems, based on real-world system configurations commonly used in 200–1500 m³/day modular plants.

For a general RO pump lifespan guide (all pump types in the RO process), see: [this article].

Table of Contents

ToggleWhy Pump Selection Is Different in Containerized SWRO Systems

In traditional large SWRO plants, pumps are often treated as standalone assets installed in pump rooms with generous space, redundancy, and on-site tuning flexibility.

Containerized SWRO systems follow a very different philosophy:

- Pre-engineered and pre-assembled in a 40’ ISO container

- Designed as “plug-and-run” units

- Commissioned rapidly with minimal on-site adjustment

- Expanded by adding parallel modules rather than scaling individual equipment

In this context, the high pressure pump becomes part of a closed, highly constrained system, where controllability and stability are often more important than peak performance.

Typical Operating Profile of Containerized SWRO Systems

Modern containerized SWRO platforms share several common characteristics that directly affect pump selection.

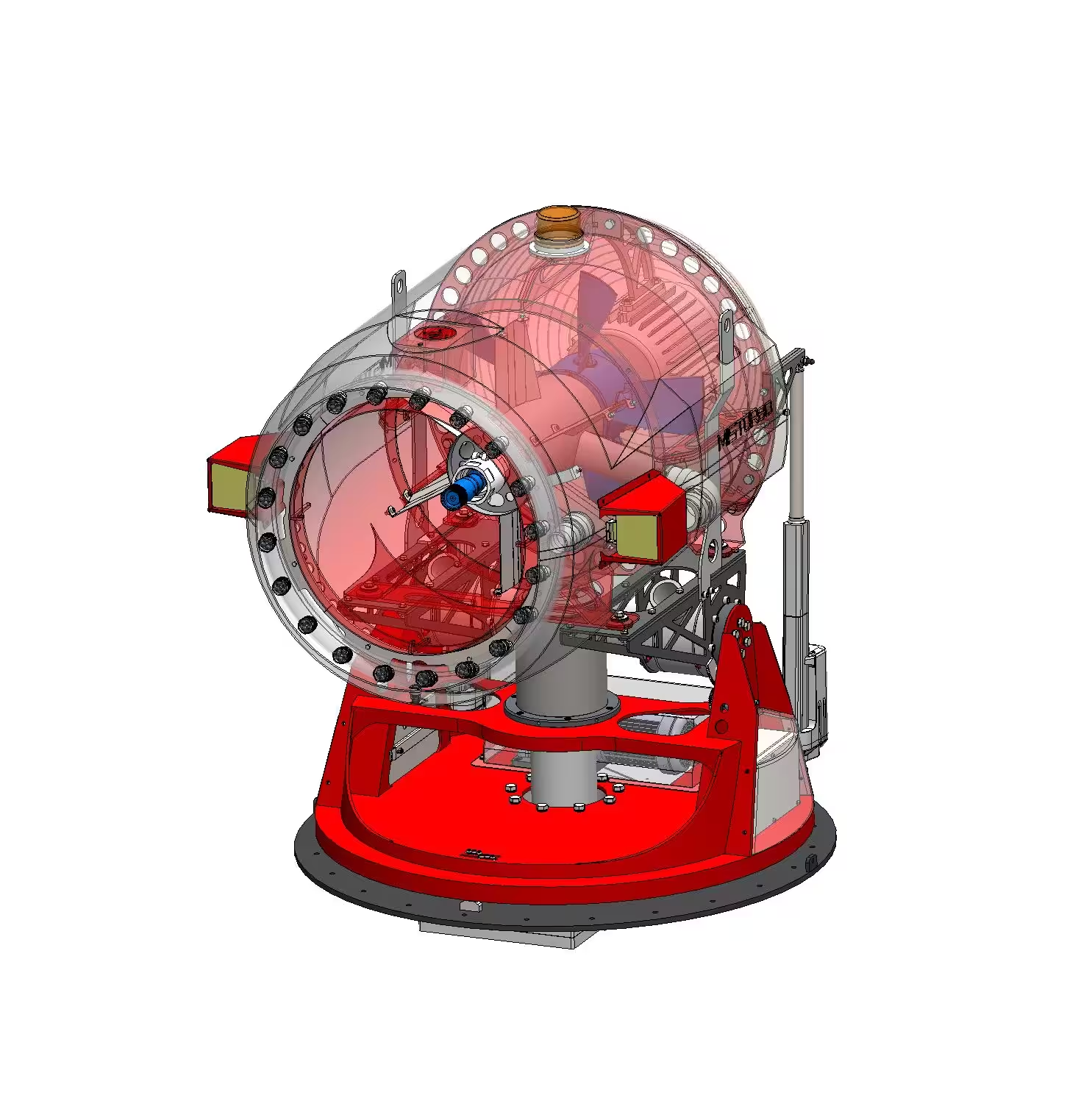

A representative example is a modular system integrating RO membranes, CIP, permeate flushing, ERD, and PLC-based control within a single container.

Modular Capacity Ranges

Containerized SWRO systems are typically offered in standardized capacity blocks such as:

- 200 m³/day

- 500 m³/day

- 1000 m³/day

- 1500 m³/day

Plant expansion is achieved by adding parallel trains.

Selection impact:

Pump platforms that can cover multiple capacity ranges simplify spare parts strategy and reduce lifecycle complexity.

Integrated Automation and Remote Monitoring

These systems usually include:

- PLC + HMI control

- Ethernet connectivity for remote monitoring

- VFDs for both RO feed pumps and high pressure pumps

- Comprehensive alarm logic (pressure, flow, electrical protection)

Selection impact:

The pump must respond predictably to speed control and integrate cleanly into pressure-based control loops.

Energy Recovery as a Standard Component

Energy recovery devices such as turbocharger-type ERDs or isobaric ERDs are standard in containerized SWRO systems, often recovering around 40–50% of hydraulic energy.

Selection impact:

The high pressure pump no longer operates against a simple system curve. It must work in tandem with the ERD, maintaining stable membrane feed pressure under dynamic conditions.

Define the Real Operating Pressure Range — Not Just Maximum Pressure

A common mistake in SWRO pump selection is focusing only on maximum allowable pressure.

In practice:

- Typical SWRO membrane operating pressure is 55–70 bar

- Higher salinity, low temperature, or membrane aging may push pressure toward 80–85 bar

Engineering rule:

Select a pump that operates comfortably and continuously within the expected operating range, rather than one that only meets the maximum pressure at its mechanical limit.

Operating near the upper limit increases wear, reduces efficiency stability, and shortens maintenance intervals.

Flow Rate Matching in Modular SWRO Systems

In containerized systems, flow rate is usually fixed by membrane array design and recovery ratio.

Key considerations:

- Avoid oversizing “just in case”

- Match pump flow to membrane design point

- Use VFD adjustment for fine tuning rather than throttling

Engineering rule:

The selected pump should deliver the required flow at nominal speed, leaving speed margin for adjustment rather than relying on continuous operation at extreme RPM.

VFD Compatibility Is Not Optional

Variable frequency drives are standard in containerized SWRO systems, used for:

- Soft start and ramp-up

- Pressure stabilization during start-up

- Adaptation to feedwater temperature and salinity changes

- Controlled shutdown and flushing sequences

Pump selection checklist for VFD operation:

- Defined continuous minimum operating speed, typically defined by bearing lubrication and volumetric stability rather than motor capability

- Stable volumetric behavior at partial load

- No sensitivity to low-speed torque fluctuations

Pumps designed primarily for fixed-speed operation may appear acceptable on paper but often show unstable behavior when operated continuously under VFD control.

Axial Piston Pumps vs. Multistage Centrifugal Pumps in Containerized SWRO

In containerized SWRO systems, two pump technologies are commonly considered for high pressure duty:

multistage centrifugal pumps and axial piston high pressure pumps.

While both can achieve the required pressure levels, their behavior within compact, VFD-controlled, ERD-assisted systems differs fundamentally.

Axial piston pumps are positive displacement machines. Flow rate is directly proportional to rotational speed, allowing precise pressure and flow control under VFD operation. This characteristic enables stable performance across a wide operating envelope and maintains high efficiency at partial load.

Multistage centrifugal pumps rely on head generation through multiple impeller stages. Their efficiency typically peaks near a narrow design point and degrades more rapidly under off-design or low-speed operation, which is common in containerized systems with variable operating conditions.

For modular SWRO plants where:

– VFD operation is continuous

– ERD interaction is dynamic

– partial-load operation is frequent

axial piston high pressure pumps often provide higher system efficiency, lower specific energy consumption, and more predictable control behavior.

Interaction Between High Pressure Pump and ERD

In ERD-assisted SWRO systems, the pressure seen by the membranes is the result of combined pump output and energy recovery contribution.

During:

- Start-up

- Shutdown

- Load changes

- Flush cycles

the pump must adapt smoothly to changing hydraulic conditions.

Engineering rule:

Select a pump with pressure–flow characteristics that allow fine adjustment through speed control, enabling the PLC to compensate for ERD dynamics without oscillation or frequent alarms.

Flush, CIP, and Shutdown Protection Requirements

Containerized SWRO systems typically include:

- Permeate flush on shutdown

- CIP loops integrated within the container

- Zero-recovery shutdown logic

Pump-related considerations:

- Compatibility with frequent start-stop cycles

- Internal design that tolerates flush water without damage

- Ability to integrate with automated flushing sequences

Neglecting these factors often leads to salt precipitation, scaling, or premature mechanical failure.

Material Selection for Seawater Duty

Seawater service places strict demands on pump materials due to:

- High chloride concentration

- Continuous operation

- Elevated pressure levels

Engineering rule:

Pressure-containing components should use duplex or super duplex stainless steels (e.g. 2205 / 2507) for pressure-containing components, shifting corrosion risk management from operation to design.

Material selection is a lifecycle decision, not a cost optimization shortcut.

Common Pump Selection Mistakes in Containerized SWRO Projects

Based on field experience, the most frequent issues include:

- Selecting pumps based solely on maximum pressure

- Oversizing flow “for safety”

- Ignoring VFD operating behavior

- Underestimating ERD interaction

- Treating pumps as isolated components rather than part of a system

Avoiding these mistakes significantly improves commissioning success and long-term stability.

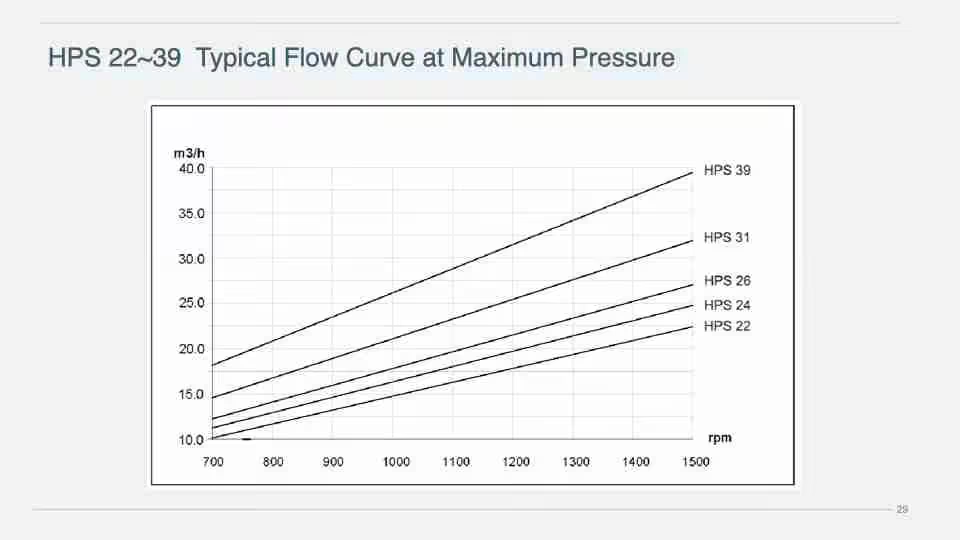

Typical Pump Selection Ranges for Modular Containerized SWRO Systems

Typical Pump Selection Ranges for 200 / 500 / 1000 / 1500 m³/day Containerized SWRO Systems

To make pump selection more practical, this section provides typical high pressure pump selection ranges for common containerized SWRO capacity blocks.

These examples are intended as engineering reference ranges, not final sizing results. Final selection should always be verified against membrane configuration, recovery ratio, feedwater salinity, temperature, and site-specific losses.

Key Assumptions for Reference Ranges

The following assumptions reflect a typical containerized SWRO design philosophy:

- Single-train, containerized SWRO module

- Seawater TDS: ~35,000 ppm

- Recovery ratio: 40–45%

- Energy Recovery Device (ERD) installed

- VFD-controlled high pressure pump

- Normal operating pressure range: 55–70 bar

- Design pressure margin refers to short-duration worst-case conditions, not continuous operation.

Typical Pump Selection Ranges by System Capacity

| SWRO Capacity | Typical Net Permeate | Indicative HP Pump Flow Range* | Typical Operating Pressure | Design Pressure Margin |

|---|---|---|---|---|

| 200 m³/day | ~8–9 m³/h | 18–22 m³/h | 55–65 bar | up to 80 bar |

| 500 m³/day | ~21 m³/h | 45–55 m³/h | 55–68 bar | up to 80–85 bar |

| 1000 m³/day | ~42 m³/h | 90–105 m³/h | 60–70 bar | up to 85 bar |

| 1500 m³/day | ~62–65 m³/h | 130–160 m³/h | 60–72 bar | up to 85 bar |

* Indicative flow ranges assume a single-train configuration with ERD integrated in the concentrate line. Pump flow refers to membrane feed flow after ERD interaction, not raw seawater intake flow.

Engineering Interpretation of the Selection Ranges

1) Why Pump Flow Is Higher Than Permeate Flow

In SWRO systems, the high pressure pump must supply membrane feed flow, not just permeate production.

The difference accounts for:

- Recovery ratio

- Concentrate (brine) flow

- ERD hydraulic balance

Selecting a pump based only on permeate flow is a common engineering error.

2) Pressure Range Matters More Than Peak Pressure

Although design pressure margins often reach 80–85 bar, continuous operation typically occurs at lower pressures.

Engineering recommendation:

Select a pump whose best efficiency and stable operating zone lies within the normal operating pressure range (55–70 bar), rather than at the extreme upper limit.

3) Speed Margin Is Preferable to Oversizing

In containerized SWRO systems:

- Fine flow and pressure adjustment is achieved via VFD

- Oversized pumps operating at very low speed tend to reduce control resolution

Engineering recommendation:

Choose a pump that meets nominal duty at mid-range speed, leaving speed margin for seasonal or water quality variations.

4) Modular Expansion Considerations

For systems designed to expand from 200 → 500 → 1000 → 1500 m³/day via parallel trains:

- Maintaining similar pump platforms across modules

- Standardizing spare parts and maintenance procedures

is often more valuable than optimizing each module independently.

How to Use These Ranges in Practice

These ranges should be used as:

- Early-stage feasibility checks

- Conceptual design guidance

- Cross-validation of vendor proposals

They are not a substitute for detailed hydraulic calculations but help engineers quickly identify reasonable pump candidates and avoid common selection mistakes.

For a deeper discussion of system-level selection philosophy, ERD interaction, and VFD control behavior. A more detailed discussion of ERD dynamics, control philosophy, and long-term operating envelopes is available in the Rohre Engineering White Paper on SWRO High Pressure Pump Selection for Containerized Systems.

A Practical Selection Checklist for Procurement Engineers

For procurement engineers evaluating high pressure pump proposals for containerized SWRO systems, the following checklist helps validate whether a selected pump truly fits the system architecture:

– Does the pump operate efficiently within the normal pressure range (55–70 bar), not just meet maximum pressure?

– Is stable VFD operation demonstrated across the expected speed range?

– Can the pump accommodate ERD interaction without control instability?

– Is the flow rate matched to membrane design rather than oversized?

– Are materials suitable for continuous seawater duty?

– Does the pump tolerate frequent start-stop, flushing, and CIP sequences?

If a pump cannot clearly satisfy these criteria, it may meet specifications on paper but introduce risk during commissioning and long-term operation.

Engineering Summary: A System-Oriented Selection Approach

In modern containerized SWRO systems, axial piston high pressure pumps align naturally with the system architecture, delivering efficiency, controllability, and lifecycle stability that are difficult to achieve with traditional multistage centrifugal designs. Selecting a high pressure pump for containerized SWRO systems requires a system-level mindset.

Rather than asking:

“What is the highest pressure pump available?”

Engineers should ask:

- Can the pump operate stably at the expected pressure range?

- Does it integrate naturally with VFD and PLC control?

- Is it compatible with ERD-assisted operation?

- Does it support flushing and modular expansion strategies?

A pump that fits the system architecture will deliver lower risk, faster commissioning, and more predictable lifecycle performance.

This article reflects general engineering principles derived from modular containerized SWRO system configurations and is intended to support pump selection decisions during system design and integration.