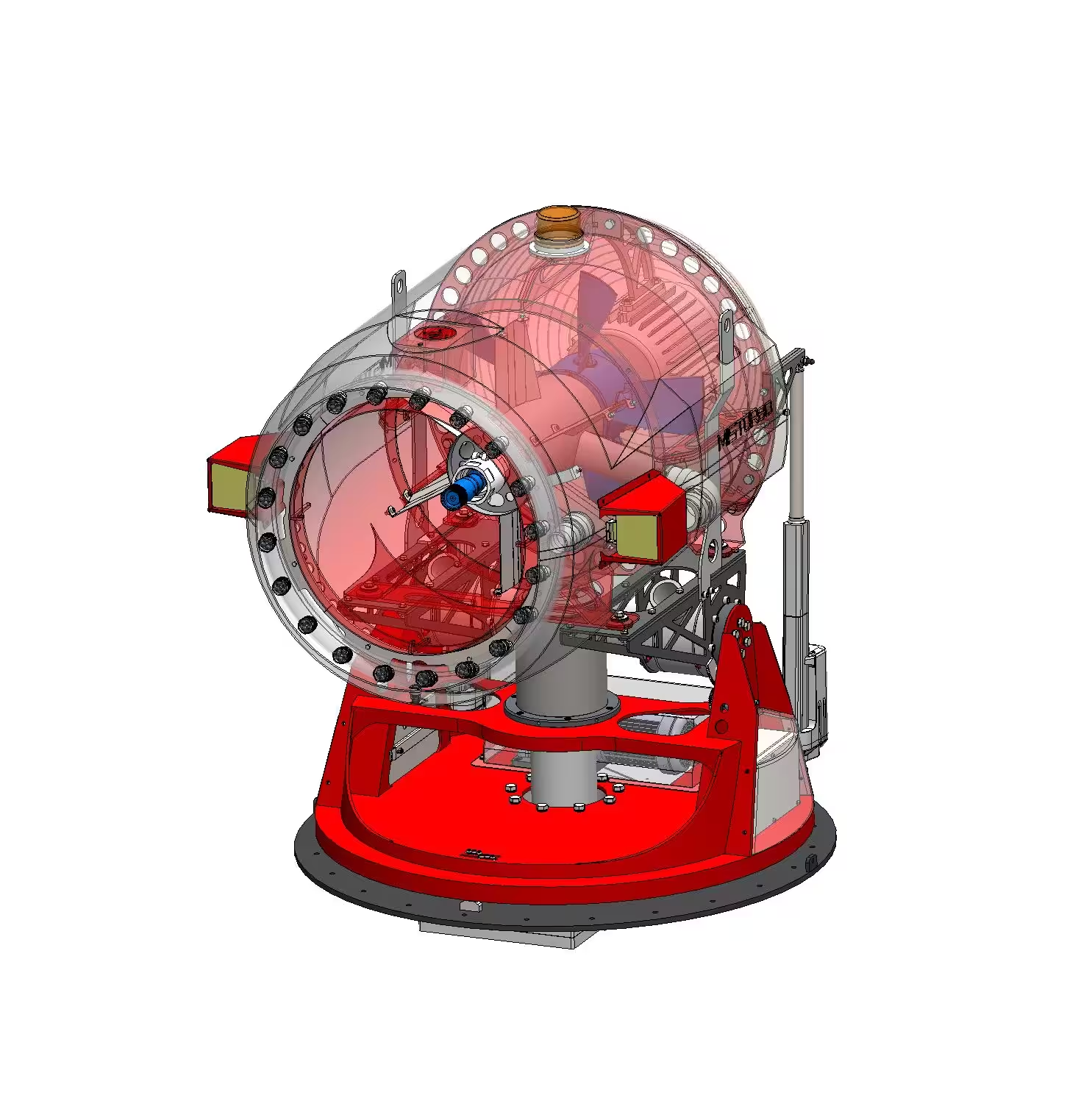

In water treatment and industrial systems, keeping your process reliable, clean, and cost-effective depends on the right high-pressure pump. That’s why we developed the Rohre HPH and HPS axial piston pumps — to help engineers and system designers meet the high-pressure needs of RO, ultrapure water, and seawater desalination systems without the risks of oil contamination or unexpected downtime.

With oil-free operation, stable performance up to 160 bar, and long-lasting design, these pumps are built to help you hit your zero liquid discharge (ZLD) goals, protect your membranes and equipment, and lower your long-term operating costs.

Table of Contents

ToggleApplications: Designed for Demanding RO Systems Like Yours

Whether you’re building or running a reverse osmosis system, you know the pressure side has to be solid — reliable, stable, and easy to maintain. That’s exactly where our Rohre HPH/HPS axial piston pumps fit in. These pumps are already being used in systems like yours, helping engineers stay ahead of performance, uptime, and environmental goals.

● Reverse Osmosis for ZLD (Zero Liquid Discharge)

In ZLD systems, pressure needs are high and constant. Our HPH pumps deliver that pressure through multi-stage RO setups, helping push water through membranes even at the final, high-concentration stage. That means better water recovery and fewer maintenance headaches.

● Ultrapure Water Systems

Clean systems need clean pumps. The oil-free design of our HPH pumps ensures that no oil ever touches your ultrapure water — and the low-pulsation output keeps your membranes and instruments running smoothly.

● Seawater Desalination

Desalination is tough on pumps. The HPS series is built with super duplex stainless steel (2507), made to handle 60–85 bar seawater RO duty without corrosion or performance drop. They’re a match for the harshest marine environments.

● Industrial Wastewater RO

When your RO system deals with salty or chemical-rich water, scaling and corrosion can shut things down fast. That’s why the HPS pumps include an integrated flush valve, letting you rinse out the internals after use — no disassembly, no extra downtime.

● High-Pressure Cleaning Systems

Need high-pressure, clean water for pipe or equipment washing? These pumps deliver steady flow without oil residue. That makes them a smart fit for clean-in-place (CIP) systems or spray stations where cleanliness matters.

● Water Mist Fire Protection & Dust Control

Rohre pumps are also used in fine mist systems for fire suppression and dust control — where quiet, reliable high pressure is a must. Their compact design, low noise, and long running life make integration easy and operation worry-free.

These are just a few examples. HPH/HPS pumps are also used in water hydraulics, high-pressure testing, and any other system requiring clean, reliable high-pressure water.

How to Choose the Right Pump for Your RO System

(Selection Made Simple for Engineers)

Picking the right pump doesn’t have to be complicated. If you know your system, we’ll help match the right model — here are the five key things you need to check:

1. What Pressure and Flow Do You Need?

This tells you which series to look at:

- HPH series – For fresh or clean water, up to 160 bar. Best for RO and ZLD systems that need high pressure.

- Ultrapure water – Pressure is usually below 100 bar, but water purity is critical.

- HPS series – For seawater or chemical wastewater, up to 85 bar, perfect for desalination.

✅ Tip: Always choose a pump that can handle more than your system’s max pressure. This prevents overloading and extends pump life.

2. What Speed Should You Run It At?

Our pumps work between 700–3500 rpm, but here’s the trick:

- 1500 rpm (at 50 Hz) is the sweet spot — stable, quiet, and cool.

- Higher speeds = more flow, but also more noise and wear.

- Lower speeds (<1000 rpm) = quieter, but you’ll need good cooling.

✅ Tip: When in doubt, design around 1500 rpm. It’s the safest and most efficient zone.

3. What Fluid Are You Pumping?

(Material Selection)

Not all water is the same — choose the right material to prevent corrosion:

| Fluid Type | Recommended Material |

| Tap / Soft water | SS304 |

| Ultrapure water | SS304 body + SS316 internals |

| Seawater / Wastewater | Duplex steel 2205 or 2507 |

✅ Tip: Not sure? Just send us your fluid info — we’ll help you decide.

📩 marketing@cncontrolvalve.com

4. How Much Motor Power Will You Need?

- The higher your flow and pressure, the bigger the motor.

- Example: HPS 0.8-1.0 at 85 bar / 3500 rpm needs 3–4 kW

- Bigger models? You may need 11 kW, 30 kW, or more.

Also consider temperature:

- Fluid temp: 2–50°C

- Hot environments or high altitudes? Use a bigger motor or extra cooling.

✅ Tip: Never under-size your motor. It’s better to go a bit bigger and run cool.

5. Is Your Inlet Pressure and Filtration Set Up Right?

- Pumps need positive inlet pressure — at least 0.5 bar, better if above 2 bar.

- No suction, no vacuum. That causes cavitation and damage.

- Filter your fluid before the pump:

- 10 μm nominal

- 25 μm absolute max

✅ Tip: A simple inline filter can protect your pump and save you a lot in the long run.

Why Engineers Choose Rohre Pumps (and Stick with Us)

We know what matters in the field — pumps that work without surprises. That’s why engineers trust ROHRE’s HPH and HPS series. Here’s how these pumps make your job easier, your system safer, and your budget happier:

✅ Oil-Free Means Worry-Free

With water as the only cooling and lubricating medium, there’s zero risk of oil contamination. That means cleaner water, fewer system shutdowns, and one less thing to maintain.

✅ Smooth Flow = Longer Membrane Life

Our multi-plunger axial design keeps the pressure steady — so your RO membranes don’t suffer from pressure spikes or vibration. It’s not just quiet, it’s protective.

✅ Built to Resist What Others Can’t

Pumping seawater or chemical waste? No problem. We offer corrosion-resistant materials like SS316 and duplex stainless steel (2205/2507) — so your pump lasts longer, even in the harshest fluids.

✅ Smart Flushing That Saves Time

Only in our HPS series: a built-in flush valve that lets you clean out salt or residue after shutdown. No disassembly needed. You rinse, and you’re ready for the next run.

✅ Designed for Hands-On Engineers

Need to swap a seal? Clean the pump head? With our modular build, it’s fast and simple. No special tools. No waiting on a service team.

✅ Run It, Forget It

Thanks to solid design and materials, these pumps just keep going — even under tough conditions. You’ll see less downtime, fewer part failures, and lower lifetime costs.

Why So Many RO System Brands Choose Rohre

When you’re selecting a high-pressure pump, you’re not just buying a machine — you’re betting on reliability, support, and peace of mind. That’s where Rohre makes a real difference.

Here’s what makes our pumps your smartest long-term choice:

🔧 Built to International Engineering Standards

Our pumps are designed and tested under strict UK and EU industrial guidelines. That means you get consistency, precision, and zero surprises — even under the most demanding conditions.

🔇 Quiet, But Powerful

Running at full pressure, our pumps register as low as 74 dB(A). That’s quiet enough for sensitive workspaces, and it reduces operator fatigue over long shifts. Quiet pumps usually mean smooth internal mechanics, which also means longer lifespan.

✅ Trusted in Real-World RO Projects

From seawater desalination to high-pressure mist firefighting, ROHRE pumps have delivered years of stable, low-failure performance for OEMs and integrators in over 40 countries. You’re not taking a risk — you’re joining a proven track record.

🔄 Modular Design Saves You Time

Need to swap a pump, upgrade a part, or shorten delivery time? Our standardized modular parts make installation and servicing fast, flexible, and hassle-free. That’s especially valuable in tight project timelines or when local maintenance matters.

We’re Not Just Selling Pumps — We’re Building Partnerships

If you’re bussiness on RO systems and relying on big-name pump brands, you’ve probably faced at least one of these:

❌ Long delivery times that throw off your project schedule

❌ Slow or no technical support when issues arise

❌ High prices that squeeze your project margin

❌ Rigid product lines with little flexibility or customization

❌ Spare parts that take months to arrive

Sound familiar?

We built Rohre pumps for engineering companies just like yours — who need trusted performance, but also flexibility, speed, and cost efficiency.

Why System Owners Switch to Rohre

When our customers make the switch, they often tell us:

“We didn’t lose performance — we just gained support, speed, and savings.”

Here’s what you can expect:

✅ Fast, Flexible Selection

We don’t just send you a catalog. Our engineers help you choose the right pump model based on your flow rate, pressure, fluid type, and system layout — ensuring a perfect match from day one. You get:

- Technical data sheets

- CAD drawings

- System integration advice

- One-on-one technical support

We speak the language of system engineers.

✅ Real OEM Support

Whether you’re building a new skid or retrofitting an old system, we make your job easier:

- 3D models for direct integration

- Interface diagrams and control pairing

- Matching with your preferred motors and drives

- Modular build for easy maintenance and fast spares

You won’t need to adjust your design to fit our pump — we adjust to fit your system.

✅ Hands-On Training for Your Team

We offer onsite or online training for your installation and maintenance team — because a good pump is only good if it’s installed and used right. We help your team avoid common mistakes and reduce commissioning time.

Rohre = Quality Without the Overhead

Our HPH/HPS axial piston high-pressure pumps are already replacing Danfoss and similar brands in:

- Seawater RO skids

- Ultrapure water systems

- High-pressure ZLD units

- Water mist fire protection packages

We give you the performance you expect — at a cost that lets you stay competitive. And we deliver in weeks, not months

Want to Try a Sample Pump?

Or need help quoting your next system?

📩 Let’s start a conversation: marketing@cncontrolvalve.com

🌐 Visit us at: rohrepumps.com

You don’t have to sacrifice quality to gain control over cost, delivery, and support. With Rohre, you get both.