Axial Piston High Pressure Pumps Manufacturer | Rohre

Discover how our axial piston high-pressure pumps drive efficiency and sustainability across a wide range of applications—from water mist firefighting and zero-discharge wastewater treatment to desalination and high-pressure cleaning. Contact us today to learn how we can elevate your operation’s performance.

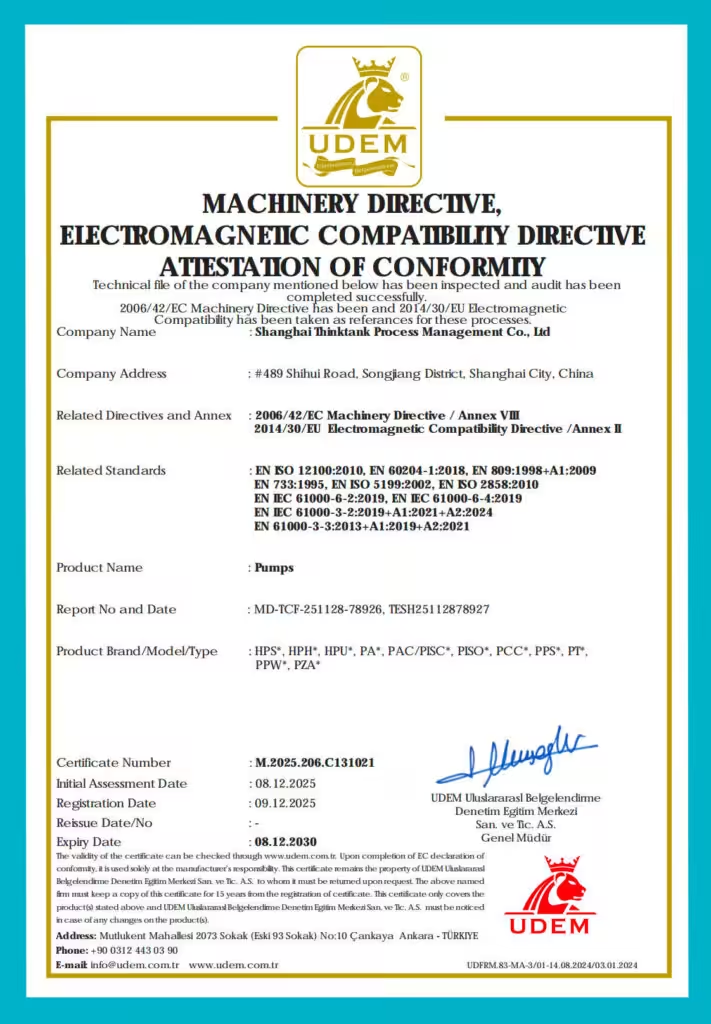

ISO 9001:2005 & CE

24/7 Service Support

Short Production Lead Time

Focus On Axial Piston Type

Why Trust Rohre?

Trusted by Global Water Mist & RO System Brands

Rohre was originally selected by an international water mist fire suppression system brand to develop and manufacture axial piston high-pressure pumps. Building on this proven foundation, our pumps are now widely used in RO and seawater desalination systems, where long-term stability, pressure consistency, and continuous operation are critical.

Growing Demand from RO & SWRO Applications

Over the past 5 years, Rohre has delivered more than 2,500 high-pressure pumps across water mist firefighting and RO systems. In recent years, demand from seawater reverse osmosis projects has grown rapidly, driven by system integrators seeking reliable axial piston pumps with predictable delivery and lifecycle performance.

Proven in Fire Protection and Desalination Projects

Rohre pumps have been deployed in over 170 projects, including high-pressure water mist fire protection systems and RO seawater desalination installations. From compact firefighting skids to large-capacity SWRO pump units, our solutions have been validated under real operating conditions.

Popular Pumps

High Pressure Pump For Fire Fighting Mist System

Our fire fighting mist system pumps are engineered to deliver high-pressure water mist for rapid fire suppression. Designed for reliability and efficiency, these pumps ensure quick response times in critical situations, minimizing water usage while maximizing fire suppression effectiveness. Perfect for industrial facilities, these pumps provide a cost-effective and sustainable fire safety solution.

High Pressure Pump For Ultrapure Water

Rohre's ultrapure water high-pressure pumps are designed to meet the stringent requirements of ultrapure water applications. These pumps ensure precise and contamination-free water flow, making them ideal for industries such as semiconductor manufacturing, pharmaceutical production, and laboratories. Built to maintain the highest levels of purity, they guarantee smooth and reliable operation in sensitive environments.

High Pressure Pump For Seawater

Our seawater high-pressure pumps are specially built to handle the challenges of corrosive environments. Perfect for desalination plants and marine applications, these pumps are designed with advanced materials that resist seawater corrosion, ensuring durability and long-lasting performance under harsh conditions. They offer a reliable solution for turning seawater into usable freshwater.

OEM High Pressure Pump

Rohre’s OEM high-pressure pumps are customizable solutions tailored to meet specific industrial needs. Whether you require specialized designs, materials, or performance standards, our OEM pumps offer flexibility without compromising on quality. These pumps provide superior performance for a variety of applications, ensuring that they meet the exact requirements of your systems.

About Rohre

Not Familiar with Rohre®️ High Pressure Pump

Hah, Because we Shanghai Thinktank Process Management Co., Ltd. is primarily known for our expertise in industrial valves. So, why do we offer this high-pressure pump product now?

Five years ago, Rohre developed a high-pressure pump exclusively for a well-known water mist fire suppression system brand. With extensive technical support from this client, our engineering team successfully created a product that perfectly replaces Danfoss high-pressure pumps. In appreciation of their guidance, we entered into a five-year confidential OEM agreement with the client.

In 2024, we started offering this product to the public, providing competitive solutions for customers in water mist fire suppression and seawater desalination systems, particularly in terms of price and delivery times. We also extend OEM services to clients requiring axial piston-type high-pressure pumps.

Test & Inspect Before Shipment

At Rohre, we know your time and budget matter. That’s why we take product inspection seriously — and make it visible to you.

Before shipment, we will send you a complete inspection report including:

CE Approval NB2292

- CE Certificate

- High-resolution photos of each pump

- Testing videos showing real performance

- Measured dimensions and key tolerances

- Function tests and pressure checks

- Final QA checklist signed by our engineers

Even if you’re not at our factory, you’ll see every detail — clearly and confidently. We understand what our customers expect, and we make sure nothing is left to chance.

You Get Full Visibility. We Deliver Peace of Mind.

Get An Instant Quote

Note: Your details are kept strictly confidential as per our Company Privacy Policy.

The Latest News

Choosing the Right Material for Your High-Pressure Pump 2205 vs. 316L vs SS304

When selecting materials for a high-pressure pump, it is crucial to consider factors such as strength, corrosion resistance, and long-term reliability. The pump’s environment and intended application can heavily influence which material is best suited for its components. Among various stainless steels, 2205 duplex stainless steel, 316L, and 304 are