Description

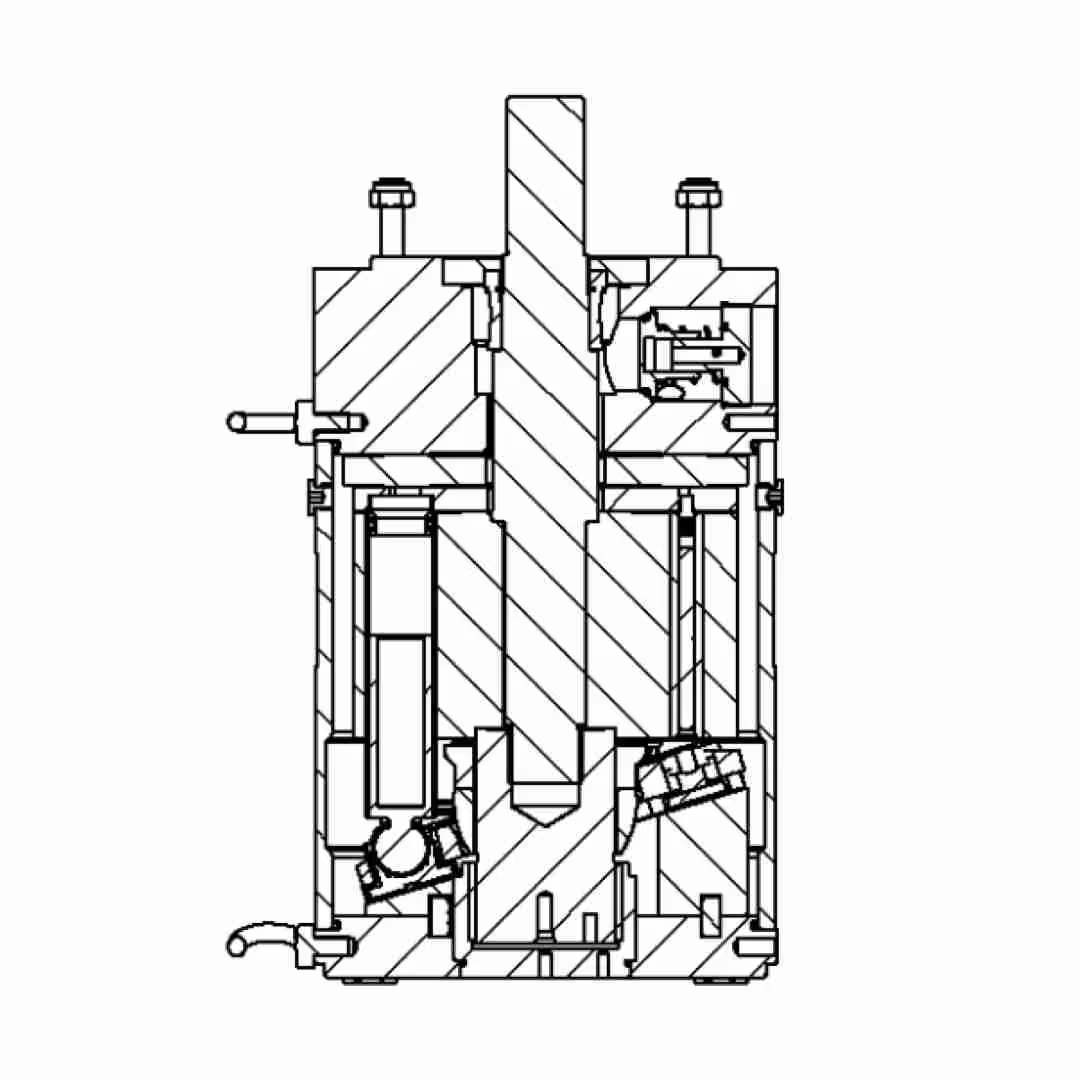

The Axial Piston High Pressure Pump HPS 22~39 is engineered with a two-port design, primarily intended for use in pump group systems. It is crucial to note that the pump is not self-priming; the inlet pressure must always remain positive. Failure to maintain positive inlet pressure will result in permanent damage to the pump.

Operational Guidelines

- Inlet Pressure Requirement:

Ensure that the inlet pressure is always positive. If the supply flow cannot guarantee positive pressure, the pump will fail. - Ensuring Positive Pressure:

The simplest way to verify positive inlet pressure is to disconnect the inlet pipe and measure the flow. When the water tank is at its lowest liquid level, the supply flow must be at least 20% greater than the pump’s delivery flow. - Filters on Direct Water Supply:

Avoid installing filters between the pump and water tank in direct water supply setups unless a pressure switch is installed on the inlet pipe to prevent negative pressure from affecting the pump.

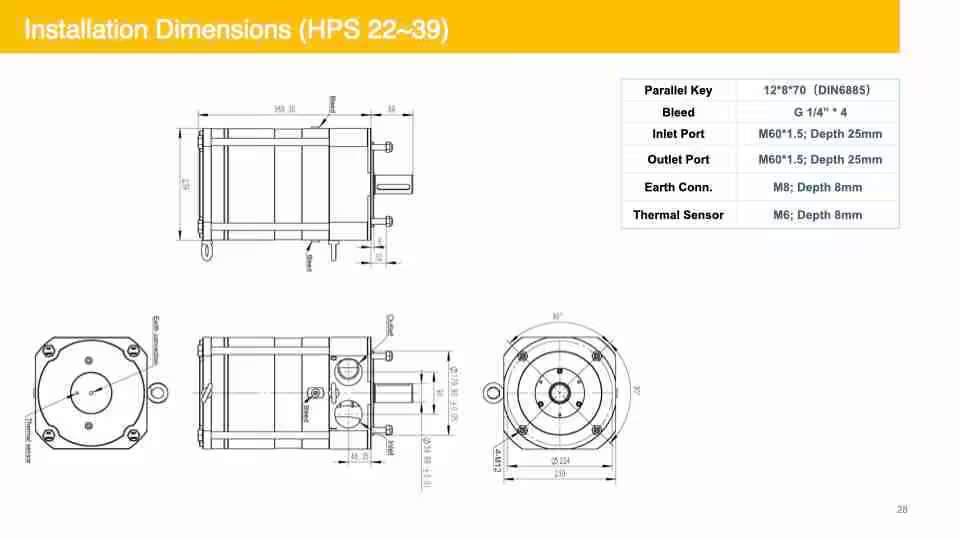

Pump Installation

- Electric Pump Set:

Use a standard bell housing and coupling to connect the pump to the B5 motor flange. The pump should not bear axial or radial loads on the output shaft. Gear couplings are preferred to avoid such stresses.

Operating Conditions

- Temperature Range:

The pump operates at optimal performance between 2°C and 50°C.- For temperatures below freezing, environmentally safe antifreeze is required.

- For temperatures above 50°C, pump efficiency may decrease, and the maximum operating temperature must be specified during the order process.

- Fluid Compatibility:

The pump is designed for use with:- Drinking water.

- Industrial water (e.g., distilled, reverse osmosis, or demineralized water).

Standard construction supports seawater; however, due to its higher corrosivity, long-term use may require upgraded materials.

Filtration Requirements

- Inlet Water Filtration:

All water entering the pump must be filtered to a nominal rating of 10 μm (absolute rating of 25 μm). - Closed Loop Systems:

Backflow filtration is an option in these systems. High-pressure filtration is also available but is generally more costly.

| Pumps Model | 22 | 24 | 26 | 31 | 39 |

| Displacement (cc/rev) | 254.5 | 280.6 | 306.8 | 360 | 441.4 |

| Housing Material | 2205/2507 | 2205/2507 | 2205/2507 | 2205/2507 | 2205/2507 |

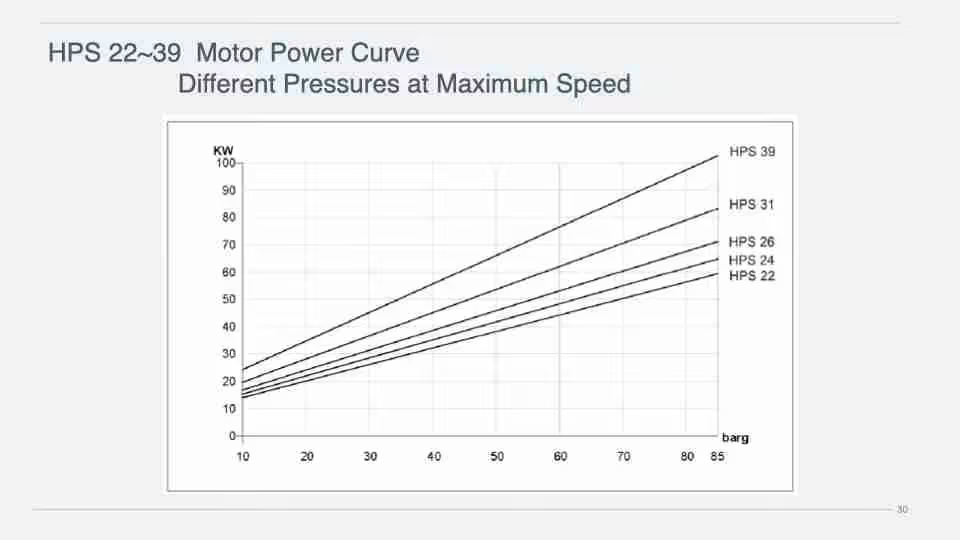

| Min. Outlet Pressure(barg) | 10 | 10 | 10 | 10 | 10 |

| Max. Outlet Pressure(barg) | 70 (1500rpm) 85 (1200rpm) | 70 (1500rpm) 85 (1200rpm) | 70 (1500rpm) 85 (1200rpm) | 70 (1500rpm) 85 (1200rpm) | 70 (1500rpm) 85 (1200rpm) |

| Inlet Pressure Continuous (barg) | 2-5 | 2-5 | 2-5 | 2-5 | 2-5 |

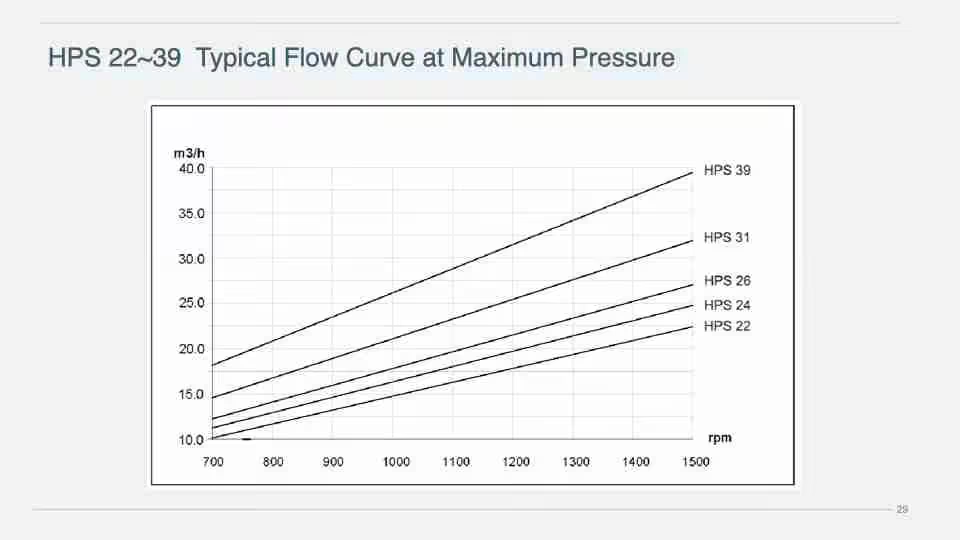

| Flow Rate (m3/h) (85barg, 700 rpm) | 10.10 | 11.20 | 12.20 | 14.53 | 18.10 |

| Flow Rate (m3/h) (85barg, 1000 rpm) | 14.76 | 16.35 | 17.85 | 21.08 | 26.00 |

| Flow Rate (m3/h) (85barg, 1200 rpm) | 17.80 | 19.68 | 21.46 | 25.40 | 31.45 |

| Flow Rate (m3/h) (70barg, 1500 rpm) | 22.18 | 24.5 | 26.76 | 31.65 | 39.10 |