Description

Design and Usage

HPR/H 8~12.5 pumps are equipped with two ports and are primarily utilized in pump group systems. These pumps are not self-priming and require a positive inlet pressure at all times. Failure to maintain positive inlet pressure can result in permanent pump damage.

To ensure proper operation, detach the pump’s inlet pipe and measure the flow rate. When the water tank’s liquid level is at its lowest, the supply flow must be at least 20% greater than the pump’s delivery flow. This ensures positive inlet pressure is maintained during operation.

Installation Recommendations

- Avoid placing a filter between the water tank and the pump for direct water supply systems, unless a pressure switch is installed on the inlet pipe to prevent negative inlet pressure.

- The pump inlet pressure must remain positive at all times for optimal performance and to prevent damage.

Electric Pump Set

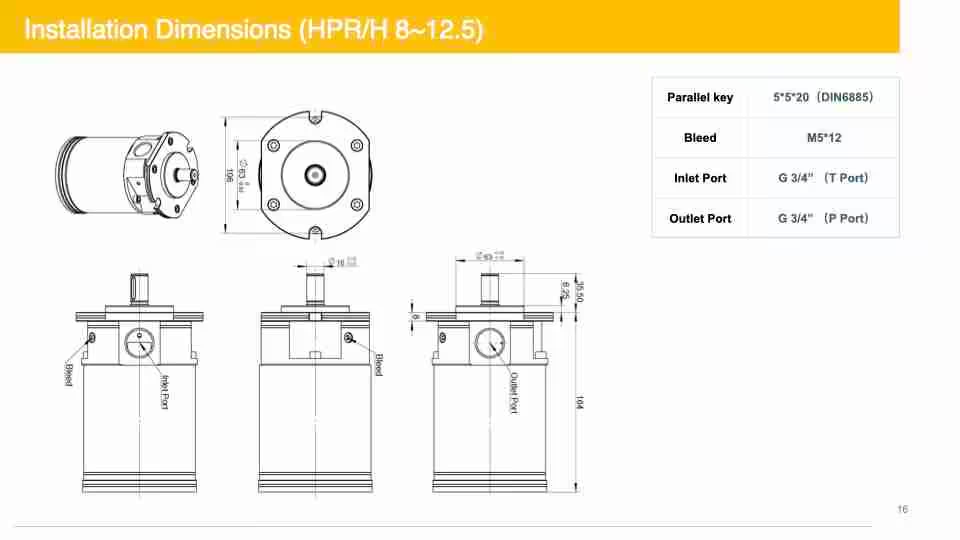

The pump should be connected to a B5 motor flange using a standard bell housing and coupling. It is essential to prevent axial or radial loads on the pump’s output shaft. Gear couplings are recommended for minimizing stress and improving operational reliability.

Operating Temperature

The HPR/H 8~12.5 operates effectively within a temperature range of 2℃ to 50℃:

- For sub-zero temperatures, environmentally friendly antifreeze is required.

- Operation above 50℃ is possible; however, it may reduce volumetric efficiency. Specify the maximum operating temperature when placing an order for pumps designed for higher-temperature applications.

Filtration

All water entering the pump must be pre-filtered with a nominal rating of 10 μm (absolute rating of 25 μm).

- For closed-loop systems, backflow filtration is acceptable.

- High-pressure filtration can also be utilized but is typically a more expensive option.

Fluid Compatibility

The standard pump design is compatible with potable water and industrial water, such as distilled water, reverse osmosis water, or demineralized water. Depending on the specific operating environment, adjustments to the sealing materials or internal structure may be necessary.

The pump can also handle seawater in its standard configuration. However, due to the corrosive nature of seawater, extended operation may require higher-quality materials for enhanced durability and long-term performance.

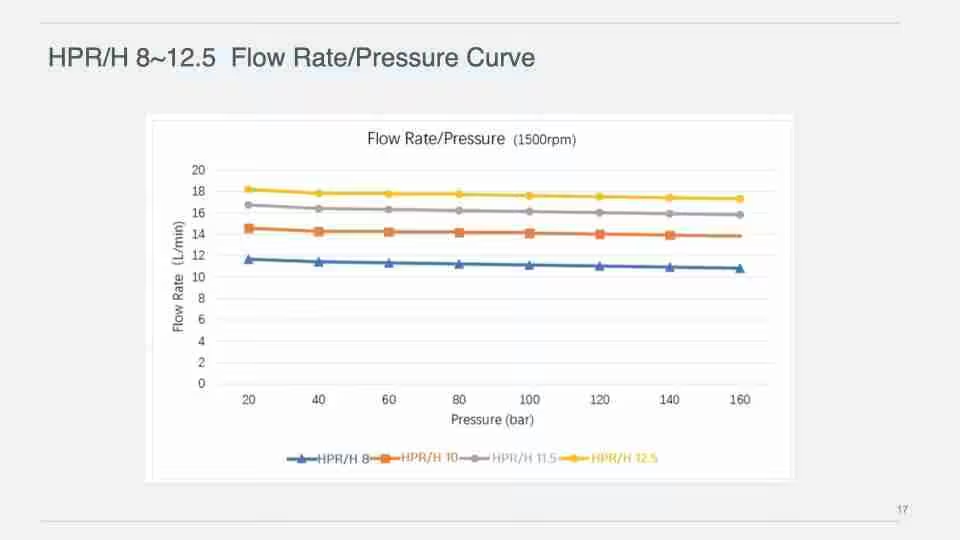

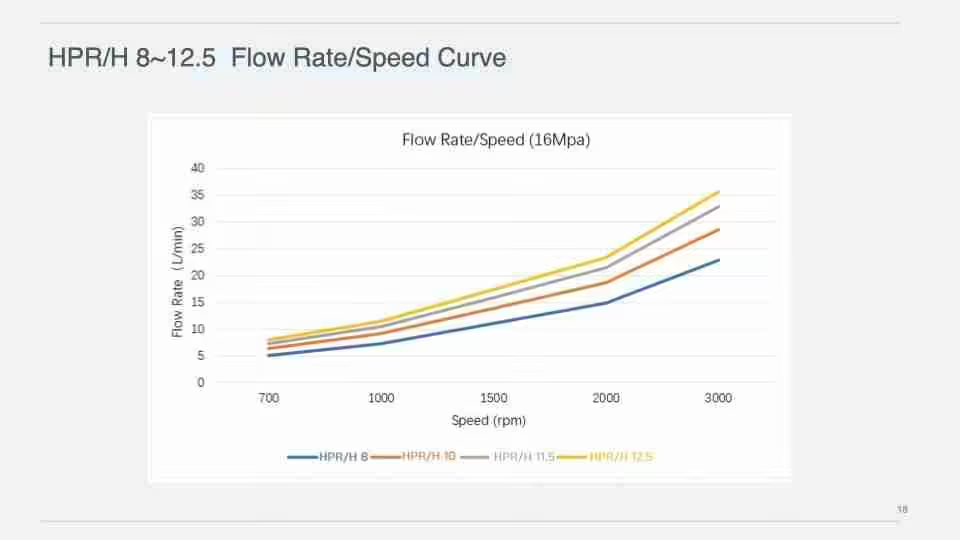

| Pumps Model | 8 | 10 | 11.5 | 12.5 |

| Displacement (cc/rev) | 8 | 10 | 11.5 | 12.5 |

| Housing Material | ASTM 304 / ASTM 316L | ASTM 304 / ASTM 316L | ASTM 304 / ASTM 316L | ASTM 304 / ASTM 316L |

| Min. Outlet Pressure(barg) | 30 | 30 | 30 | 30 |

| Max. Outlet Pressure(barg) | 160 | 160 | 160 | 160 |

| Inlet Pressure,Continuous(barg) | 0.1-5 | 0.1-5 | 0.1-5 | 0.1-5 |

| Min. Speed,Continuous (rpm) | 700 | 700 | 700 | 700 |

| Max. Speed (rpm) | 3000 | 3000 | 3000 | 3000 |

| Flow Rate (L/min) (16Mpa,700 rpm) | 5 | 6.3 | 7.2 | 7.9 |

| Flow Rate (L/min) (16Mpa,1000 rpm) | 7.2 | 9.1 | 10.4 | 11.4 |

| Flow Rate (L/min) (16Mpa,1500 rpm) | 11.0 | 13.8 | 15.8 | 17.3 |

| Flow Rate (L/min) (16Mpa,2000 rpm) | 14.8 | 18.6 | 21.4 | 23.3 |

| Flow Rate (L/min) (16Mpa,3000 rpm) | 22.8 | 28.5 | 32.8 | 35.6 |

| Power Consumption (KW) (16Mpa,1500 rpm) | 3.4 | 4.2 | 4.9 | 5.3 |

| Min. Media Temperature (°C) | 2 | 2 | 2 | 2 |

| Max. Media Temperature (°C) | 50 | 50 | 50 | 50 |

| Sound Pressure Level (dB) * | 76 | 76 | 76 | 76 |

| Weight (kg) | 8.6 | 8.6 | 8.6 | 8.6 |

| Integrated Flush Valve | YES | YES | YES | YES |