In every seawater RO plant I’ve been involved with, the high-pressure pump has always been the point everyone pays the most attention to. It’s the part that keeps the membranes working and the water flowing. If the pump isn’t right, nothing else matters.

When engineers ask about “RO High Pressure Pump Specifications,” they don’t just want a list of numbers. They want to know what actually works in the field: which materials last, what pressure range to design for, and how often the pump will need attention. Here I’ll walk through the main points we look at when specifying Rohre pumps for RO desalination systems.

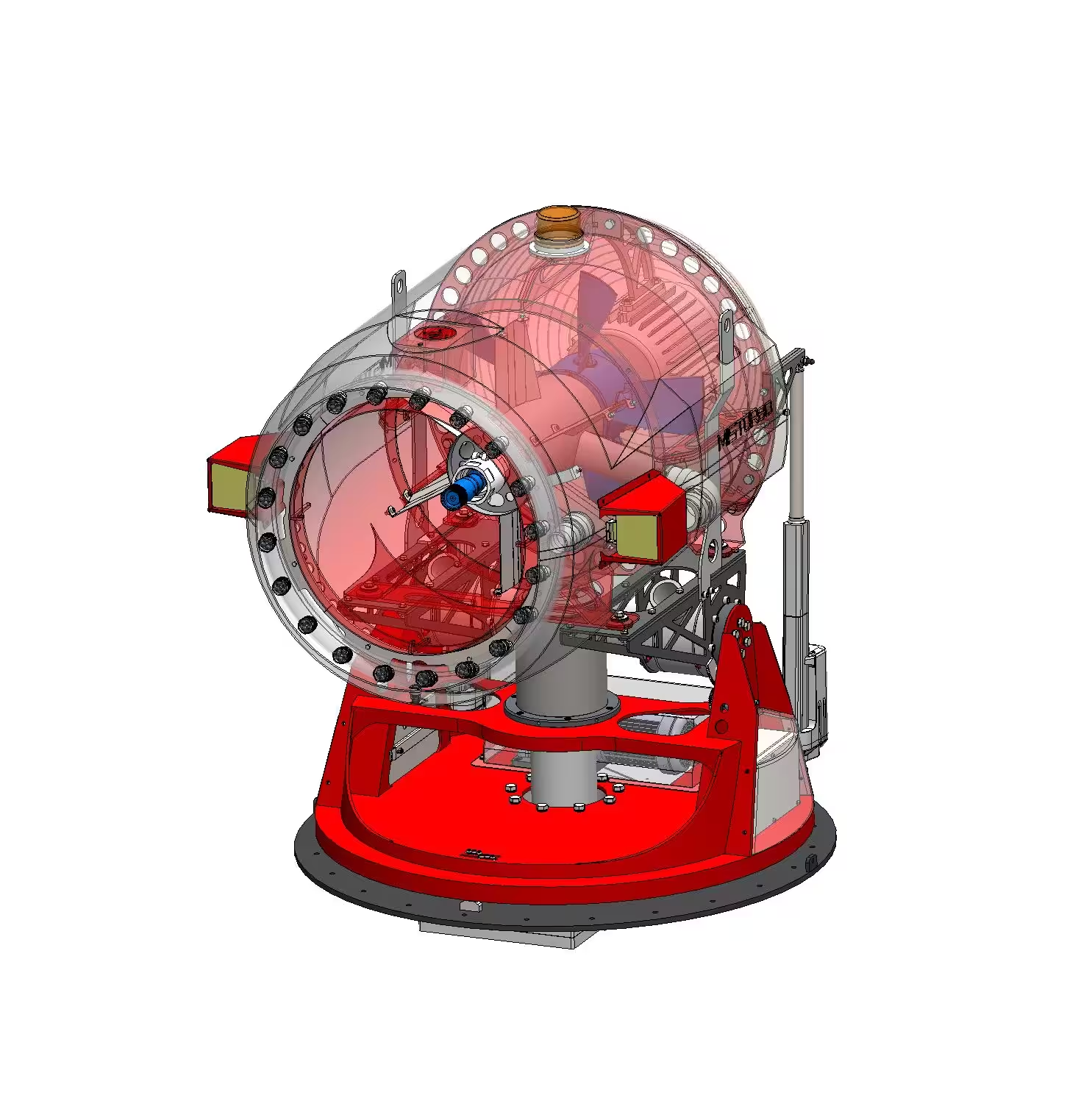

Key Specifications (Rohre Pump Example)

Flow Rate

Our axial piston high-pressure pumps are designed for 0.8–39 m³/h, which covers most seawater RO skids and modular desalination systems. For larger plants, multiple pumps are usually installed in parallel.

Inlet Pressure

Best operating condition is with an inlet pressure of 2–4 bar. This ensures stable piston operation, prevents cavitation, and extends seal life.

Outlet Pressure

The pump can deliver up to 85 bar, which is sufficient for seawater RO systems (typically 60–80 bar) and provides a safety margin for process variations.

Materials of Construction

- Pump casing: Duplex Stainless Steel 2205

- Internal wetted parts: Super Duplex Stainless Steel 2507

- Other components: Super Duplex Stainless Steel 2507 pistons and PEEK wear parts for high abrasion resistance

This material combination offers excellent resistance against seawater corrosion and long service intervals in continuous operation.

Technical Data Table

| Specification | Rohre Axial Piston Pump Example |

|---|---|

| Flow Rate Range | 0.8–39 m³/h |

| Best Inlet Pressure | 2–4 bar |

| Maximum Outlet Pressure | 85 bar |

| Pump Casing Material | Duplex SS 2205 |

| Internal Wetted Parts | Super Duplex SS 2507 |

| Pistons / Wear Parts | Super Duplex Stainless Steel 2507/PEEK |

If you need detailed drawings, specification sheets, or want to compare options for your project, our engineering team is available to support you.