About Röhre RO Pumps

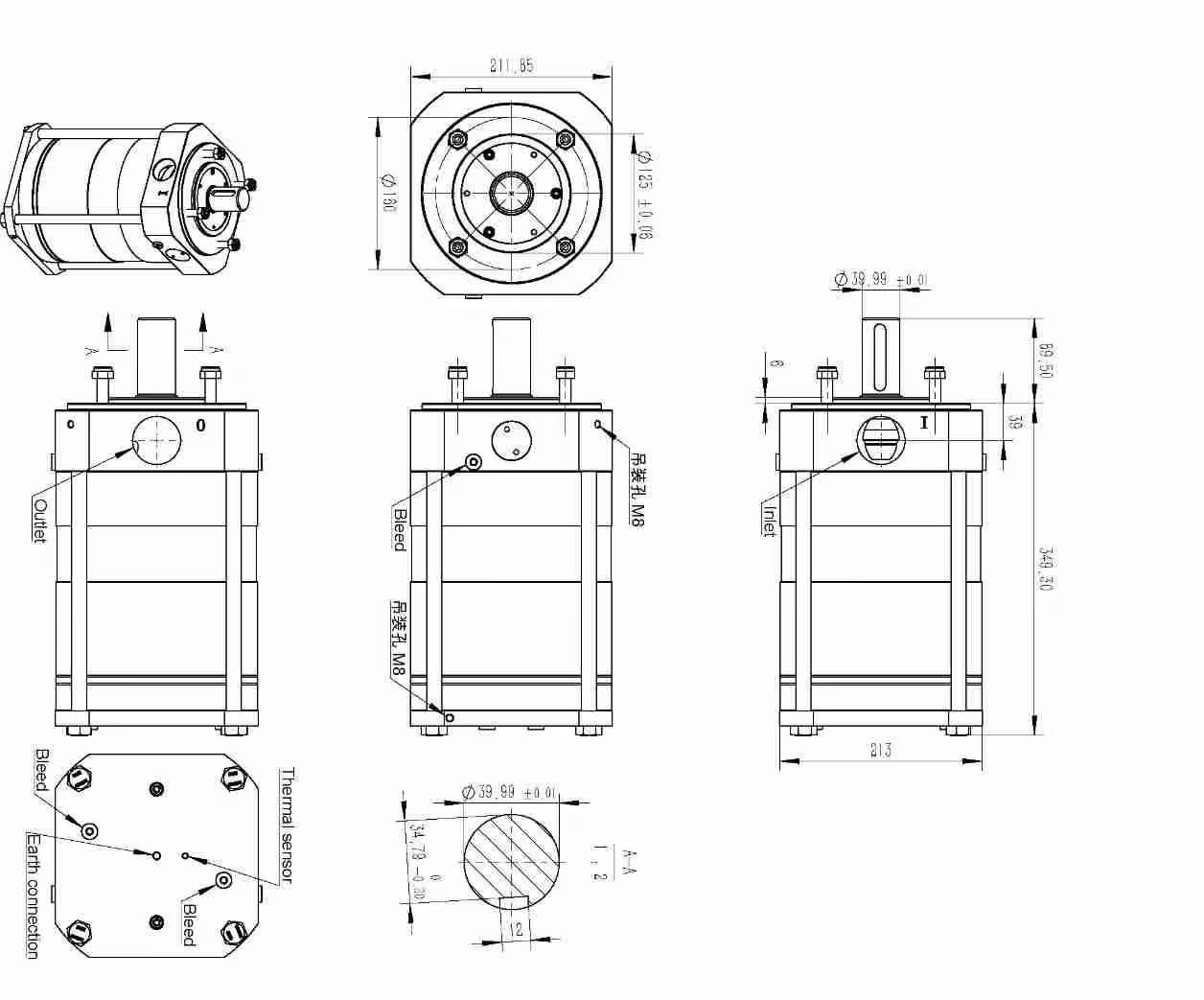

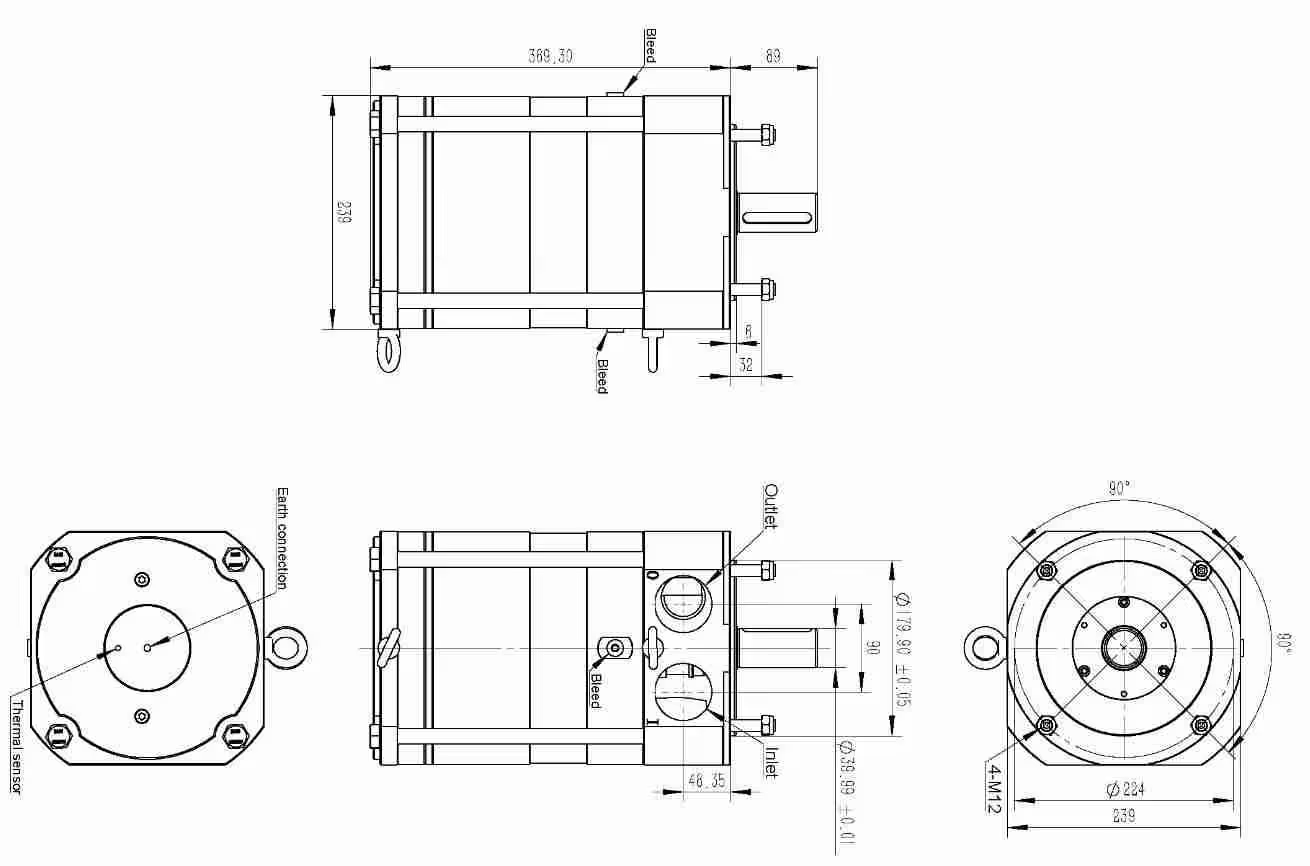

Röhre Pumps designs and manufactures axial piston high pressure pumps specifically for reverse osmosis (RO) systems.

Our pumps are compact, oil-free, and engineered for continuous seawater desalination duty.

We work with RO system manufacturers, desalination skid suppliers, and water treatment equipment builders worldwide — providing reliable high-pressure pump solutions for continuous operation.

Choose the Right Pump for Your System

SWRO High Pressure Pump

For seawater desalination plants up to 85 bar. Technical-grade performance and corrosion-resistant materials.

RO Pump for Seawater Desalination

Designed for EPC and system builders integrating complete desalination skids.

Axial Piston RO Pump

Compact, oil-free, energy-efficient design for brackish and seawater systems.

High Pressure Pumps for RO Systems

General-purpose RO pumps for industrial and commercial water treatment.

Seawater RO Pump

For light-duty or mobile desalination units such as marine and coastal systems.

RO Pumps Overview

Röhre® HPS Series Axial Piston High Pressure Pumps cover a complete flow range from 0.12 to 39.10 m³/h, operating up to 85 bar.

All models are engineered for seawater and brackish water reverse osmosis systems, using Duplex, Super Duplex, or Titanium materials for excellent corrosion resistance.

| Pump Model | Displacement (cc/rev) | Speed Range (rpm) | Reference Flow @85 bar | Material Options | Typical Application |

|---|---|---|---|---|---|

| HPS 0.6 | 4.07 | 700–3500 | 0.34 m³/h @1500 rpm | Duplex | Lab or pilot RO systems |

| HPS 0.8 | 5.08 | 700–3500 | 0.43 m³/h @1500 rpm | Duplex | Lab or pilot RO systems |

| HPS 1.0 | 6.30 | 700–3500 | 0.54 m³/h @1500 rpm | Duplex | Small RO units |

| HPS 1.5 | 9.34 | 700–3500 | 0.80 m³/h @1500 rpm | Duplex / Super Duplex | Compact desalination units |

| HPS 1.8 | 10.21 | 700–3500 | 0.87 m³/h @1500 rpm | Duplex / Super Duplex | Compact desalination units |

| HPS 2.2 | 12.75 | 700–3500 | 1.10 m³/h @1500 rpm | Duplex / Super Duplex | Compact desalination units |

| HPS 2.5 | 15.40 | 700–3500 | 1.34 m³/h @1500 rpm | Duplex / Super Duplex | Small industrial RO |

| HPS 3.0 | 17.85 | 700–3500 | 1.55 m³/h @1500 rpm | Duplex / Super Duplex | Small industrial RO |

| HPS 3.5 | 21.56 | 700–3500 | 1.88 m³/h @1500 rpm | Duplex / Super Duplex | Small desalination skid |

| HPS 5.1 | 51.20 | 700–1800 | 4.20 m³/h @1500 rpm | Duplex / Titanium | Industrial desalination |

| HPS 6.5 | 65.80 | 700–1800 | 5.38 m³/h @1500 rpm | Duplex / Titanium | Industrial desalination |

| HPS 7.2 | 71.70 | 700–1800 | 6.00 m³/h @1500 rpm | Duplex / Titanium | Industrial RO |

| HPS 8.2 | 80.65 | 700–1800 | 6.95 m³/h @1500 rpm | Duplex / Titanium | Industrial RO |

| HPS 10.2 | 101.50 | 700–1800 | 8.86 m³/h @1500 rpm | Duplex / Titanium | Industrial desalination |

| HPS 11 | 138.40 | 700–1500 | 8.95 m³/h @1200 rpm (85 bar) | Super Duplex / Titanium | Large RO system |

| HPS 13 | 169.10 | 700–1500 | 11.00 m³/h @1200 rpm (85 bar) | Super Duplex / Titanium | Large RO system |

| HPS 16 | 187.30 | 700–1500 | 12.76 m³/h @1200 rpm (85 bar) | Super Duplex / Titanium | Large modular RO |

| HPS 17 | 196.40 | 700–1500 | 13.45 m³/h @1200 rpm (85 bar) | Super Duplex / Titanium | Large modular RO |

| HPS 19 | 220.30 | 700–1500 | 15.02 m³/h @1200 rpm (85 bar) | Super Duplex / Titanium | Large RO systems |

| HPS 21 | 251.96 | 700–1500 | 17.52 m³/h @1200 rpm (85 bar) | Super Duplex / Titanium | Large RO systems |

| HPS 22 | 254.50 | 700–1500 | 17.80 m³/h @1200 rpm (85 bar) | Super Duplex / Titanium | Industrial desalination |

| HPS 24 | 280.60 | 700–1500 | 19.68 m³/h @1200 rpm (85 bar) | Super Duplex / Titanium | Industrial desalination |

| HPS 26 | 306.80 | 700–1500 | 21.46 m³/h @1200 rpm (85 bar) | Super Duplex / Titanium | Industrial desalination |

| HPS 31 | 360.00 | 700–1500 | 25.40 m³/h @1200 rpm (85 bar) | Super Duplex / Titanium | Large desalination |

| HPS 39 | 441.40 | 700–1500 | 31.45 m³/h @1200 rpm (85 bar) | Super Duplex / Titanium | Large desalination |

Notes

Flow rates are measured at 85 bar outlet pressure.

Larger pumps (HPS 11–39) are typically tested at 1200 rpm due to torque and power limits.

Custom materials, motor coupling, and manifold configurations are available upon request.

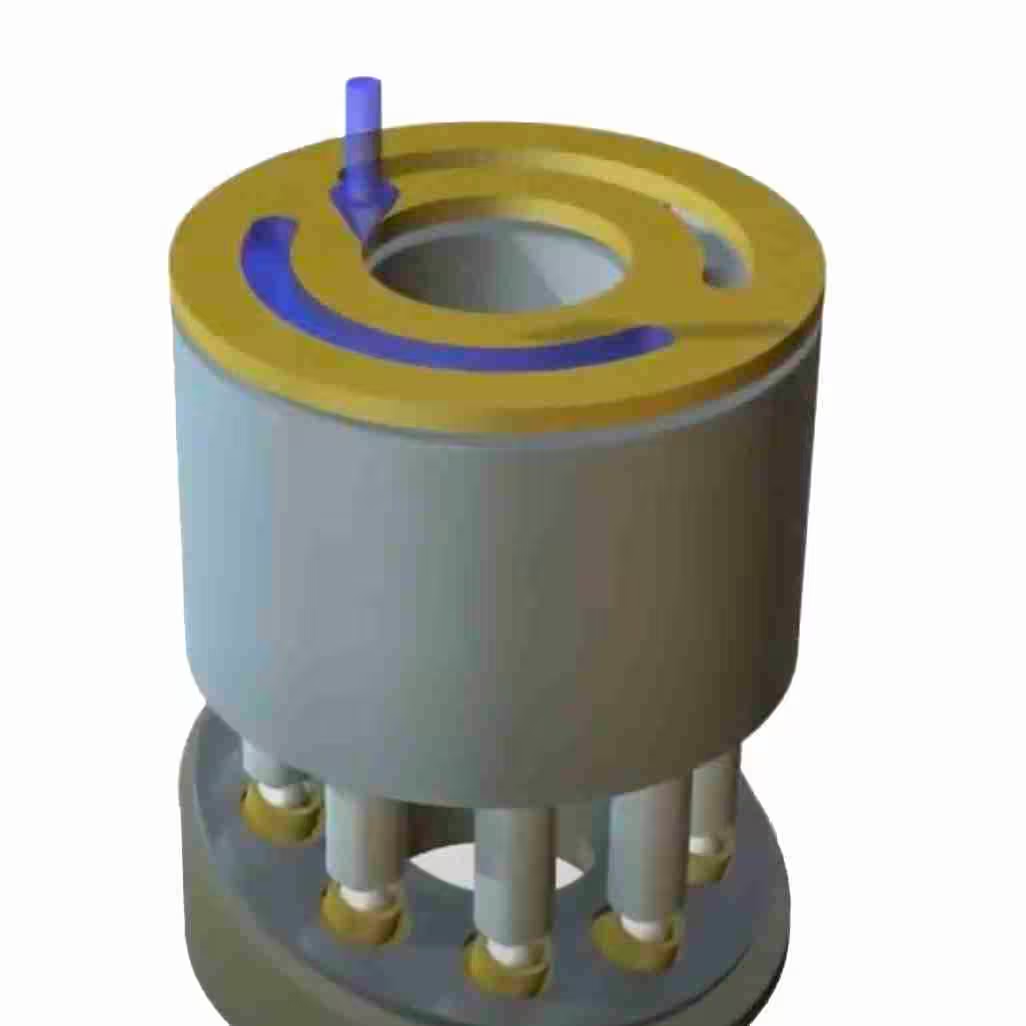

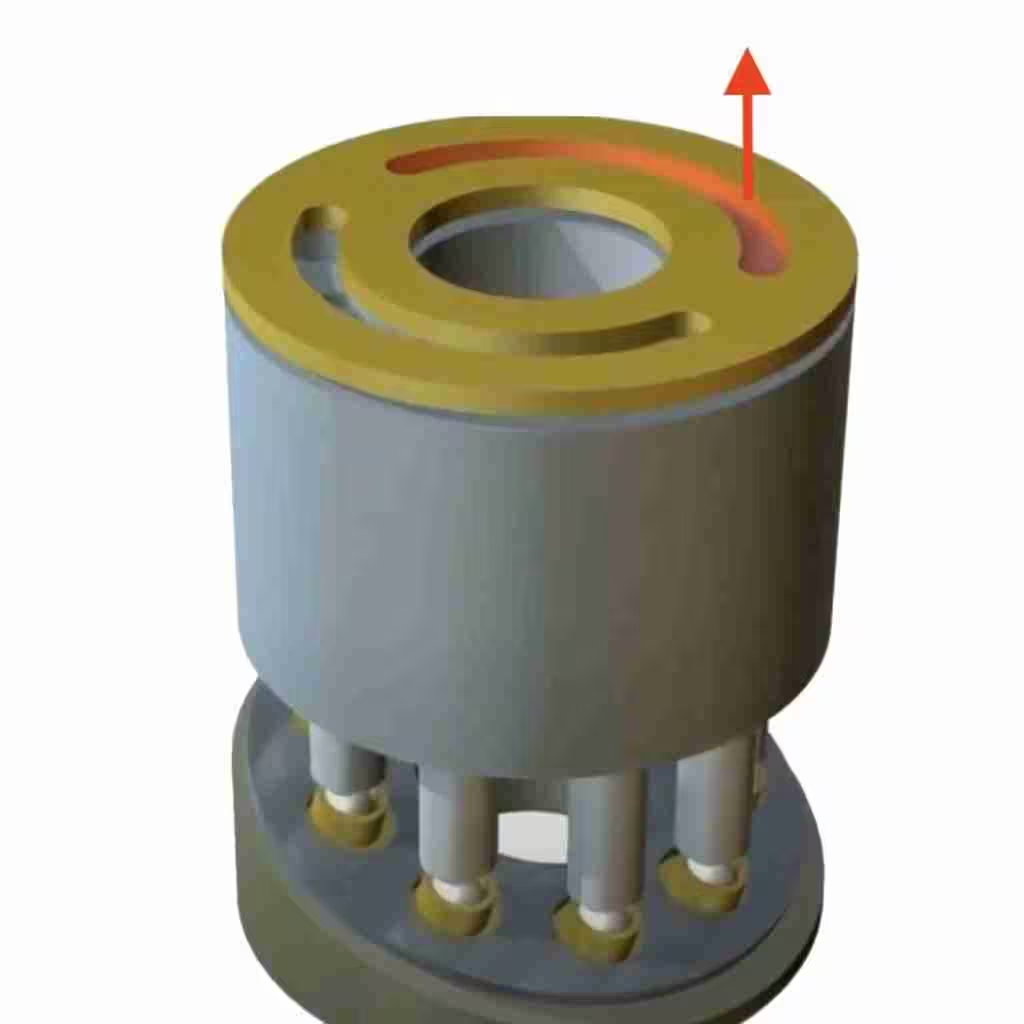

How Does Axial Piston High Pressure Pump Work?

The axial piston high-pressure pump works by rotating internal parts to pressurize fluid. It’s great for applications that need constant, high-pressure output like seawater and brackish water processing. Here’s how it works step-by-step:

- As the pump’s drive shaft rotates, fluid comes into the pump through the inlet valve plate (shown in blue) at low pressure.

- During the suction cycle, each piston moves down, drawing fluid into the piston bore.

- The piston then moves upward, compressing the fluid and pushing it out through the outlet valve plate at high pressure (shown in red).

- This pumping cycle forces the pressurized fluid out to continue through the system, making the pump effective for high-pressure applications.

- The pump design includes multiple pistons (usually between 5-9). Each piston goes through the suction and pumping cycles in sequence, which reduces pulsations and maintains a constant, pressure-independent flow.

- The flow capacity depends on factors like piston diameter, stroke length, number of pistons, and the drive shaft’s rotation speed (RPM).

- The pump uses only water as a lubricant, so you don’t need oil, which reduces maintenance. It’s made from high-quality, corrosion-resistant materials, so it’s good for tough environments, like seawater applications.

- For larger flow needs, you can put multiple pumps in parallel, which increases uptime and system reliability. The pump is compact and simple, making it easy to install in tight spaces.

- With up to 92% efficiency, these pumps are some of the most efficient pumps on the market. They stay efficient at all operating points because they have pressure-independent flow.

Simply to say, as the axial piston type high pressure pump shaft rotates, it causes the pistons to move because of the angle of the swash plate.

- During the suction phase, each piston retracts, creating a vacuum that pulls the fluid into the cylinder from the inlet port.

- In the compression phase, the piston moves forward, compressing the fluid and pushing it through the outlet port at high pressure.

Features and Benefits

Our pumps come with a lot of application knowledge behind them, so they work great in a wide range of industrial and desalination applications. We can help you with the right solution for your specific application.

Highest Efficiency

You can get up to 92% efficiency with our pumps, which is the highest in the industry. This means you use less energy, spend less money to run the pump, and get more out of it. You save a lot of money over the life of the pump.

Compact and Space-Saving Design

Rohre pumps are engineered to be up to 50% smaller than other pumps, so they work great in installations where you don’t have a lot of space. Their small size also makes it easy to put them into existing systems without a lot of changes.

Extended Service Intervals

Our pumps are designed for long-lasting performance, with extended intervals between maintenance services. This reliability minimizes downtime and maintenance costs, keeping your operations running smoothly.

User-Friendly Maintenance

Built with a service-friendly design, our pumps are easy to maintain. They don’t have a lot of moving parts, and you can get to everything you need to get to. This means you can do routine maintenance fast and get back to work.

Simple, Robust, and Highly Reliable

With a straightforward yet durable design, Rohre pumps deliver high uptime and consistent performance, even in demanding environments. They are built to operate reliably, reducing the risk of unexpected breakdowns.

Rapid Return on Investment

The combination of high efficiency, low maintenance requirements, and minimal downtime ensures a fast payback period, providing a strong return on investment for your operation.

HPS Series Axial Piston High Pressure Pump For Seawater

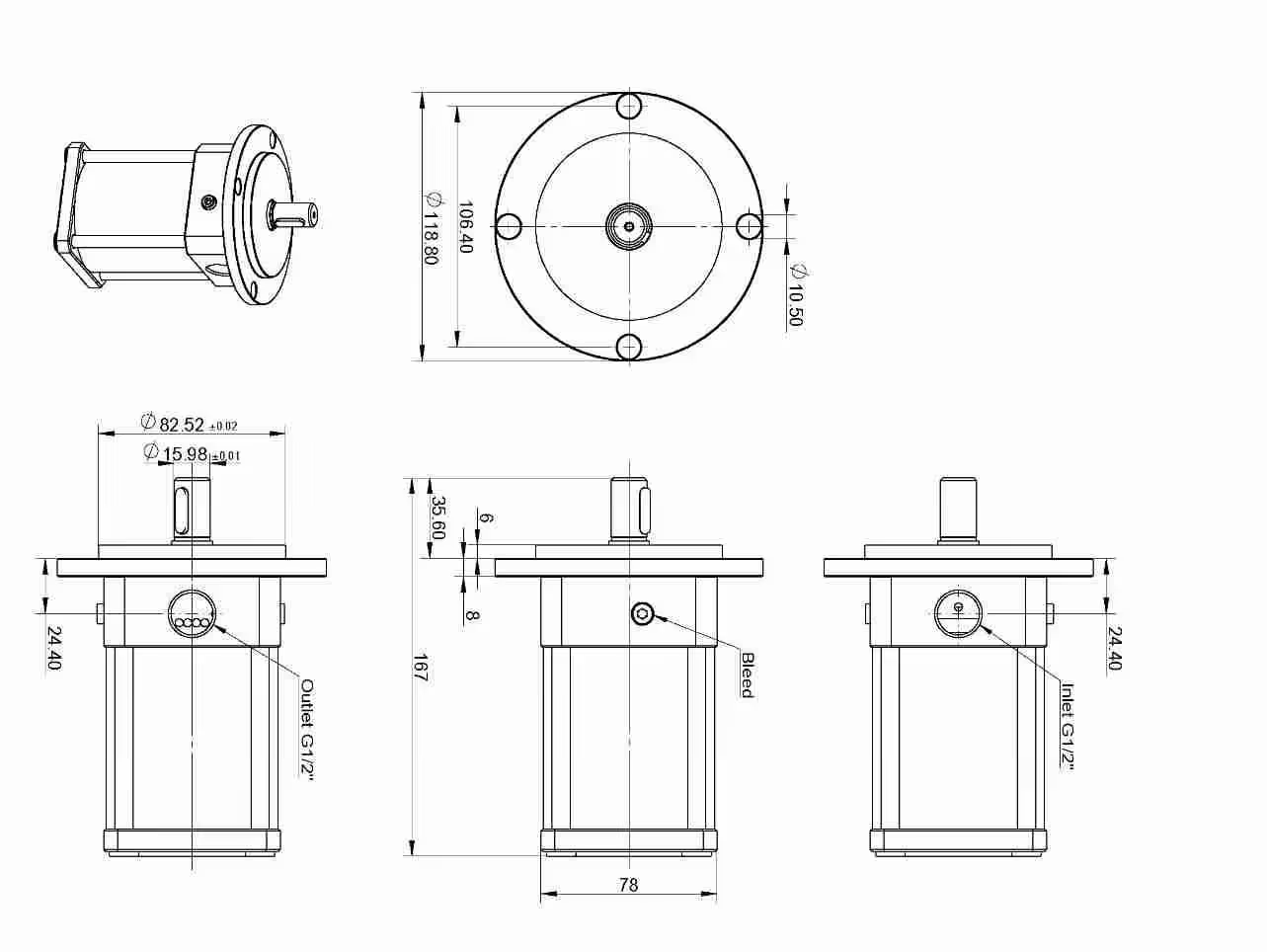

| Pumps Model | 0.6 | 0.8 | 1.0 |

| Displacement (cc/rev) | 4.07 | 5.08 | 6.3 |

| Housing Material | 2205 | 2205 | 2205 |

| Min. Outlet Pressure(barg) | 20 | 20 | 20 |

| Max. Outlet Pressure(barg) | 85 | 85 | 85 |

| Inlet Pressure Continuous (barg) | 0.5-5 | 0.5-5 | 0.5-5 |

| Flow Rate (m3/h) (85barg, 700 rpm) | 0.12 | 0.17 | 0.22 |

| Flow Rate (m3/h) (85barg, 1000 rpm) | 0.22 | 0.29 | 0.36 |

| Flow Rate (m3/h) (85barg, 1200 rpm) | 0.25 | 0.33 | 0.42 |

| Flow Rate (m3/h) (85barg, 1500 rpm) | 0.34 | 0.43 | 0.54 |

| Flow Rate (m3/h) (85barg, 1800 rpm) | 0.40 | 0.52 | 0.65 |

| Flow Rate (m3/h) (85barg, 2500 rpm) | 0.58 | 0.75 | 0.94 |

| Flow Rate (m3/h) (85barg, 3000 rpm) | 0.71 | 0.91 | 1.14 |

| Flow Rate (m3/h) (85barg, 3500 rpm) | 0.83 | 1.06 | 1.32 |

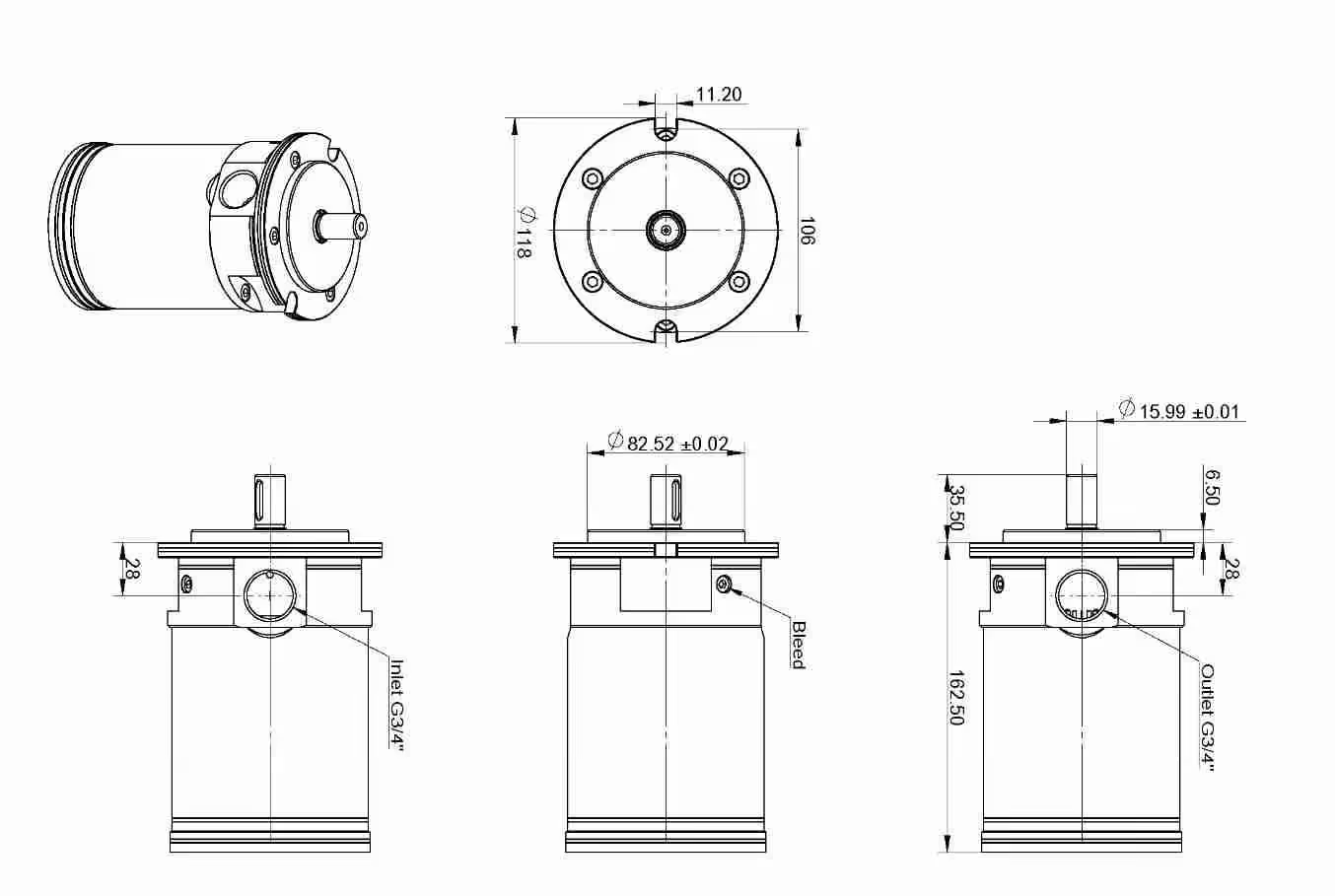

| Pumps Model | 1.5 | 1.8 | 2.2 | 2.5 | 3.0 | 3.5 |

| Displacement (cc/rev) | 9.34 | 10.21 | 12.75 | 15.4 | 17.85 | 21.56 |

| Housing Material | 2205 | 2205 | 2205 | 2205 | 2205 | 2205 |

| Min. Outlet Pressure(barg) | 20 | 20 | 20 | 20 | 20 | 20 |

| Max. Outlet Pressure(barg) | 85 | 85 | 85 | 85 | 85 | 85 |

| Inlet Pressure Continuous (barg) | 0.5-5 | 0.5-5 | 0.5-5 | 0.5-5 | 0.5-5 | 0.5-5 |

| Flow Rate (m3/h) (85barg, 700 rpm) | 0.3 | 0.34 | 0.45 | 0.57 | 0.64 | 0.76 |

| Flow Rate(m3/h) (85barg, 1000 rpm) | 0.54 | 0.58 | 0.75 | 0.90 | 1.03 | 1.24 |

| Flow Rate(m3/h) (85barg, 1200 rpm) | 0.58 | 0.64 | 0.84 | 1.03 | 1.18 | 1.39 |

| Flow Rate (m3/h) (85barg, 1500 rpm) | 0.80 | 0.87 | 1.10 | 1.34 | 1.55 | 1.88 |

| Flow Rate (m3/h) (85barg, 1800 rpm) | 0.92 | 1.0 | 1.27 | 1.58 | 1.80 | 2.11 |

| Flow Rate (m3/h) (85barg, 2500 rpm) | 1.31 | 1.42 | 1.80 | 2.22 | 2.55 | 2.98 |

| Flow Rate (m3/h) (85barg, 3000 rpm) | 1.60 | 1.73 | 2.18 | 2.68 | 3.07 | 3.58 |

| Flow Rate (m3/h) (85barg, 3500 rpm) | 1.84 | 1.99 | 2.52 | 3.56 |

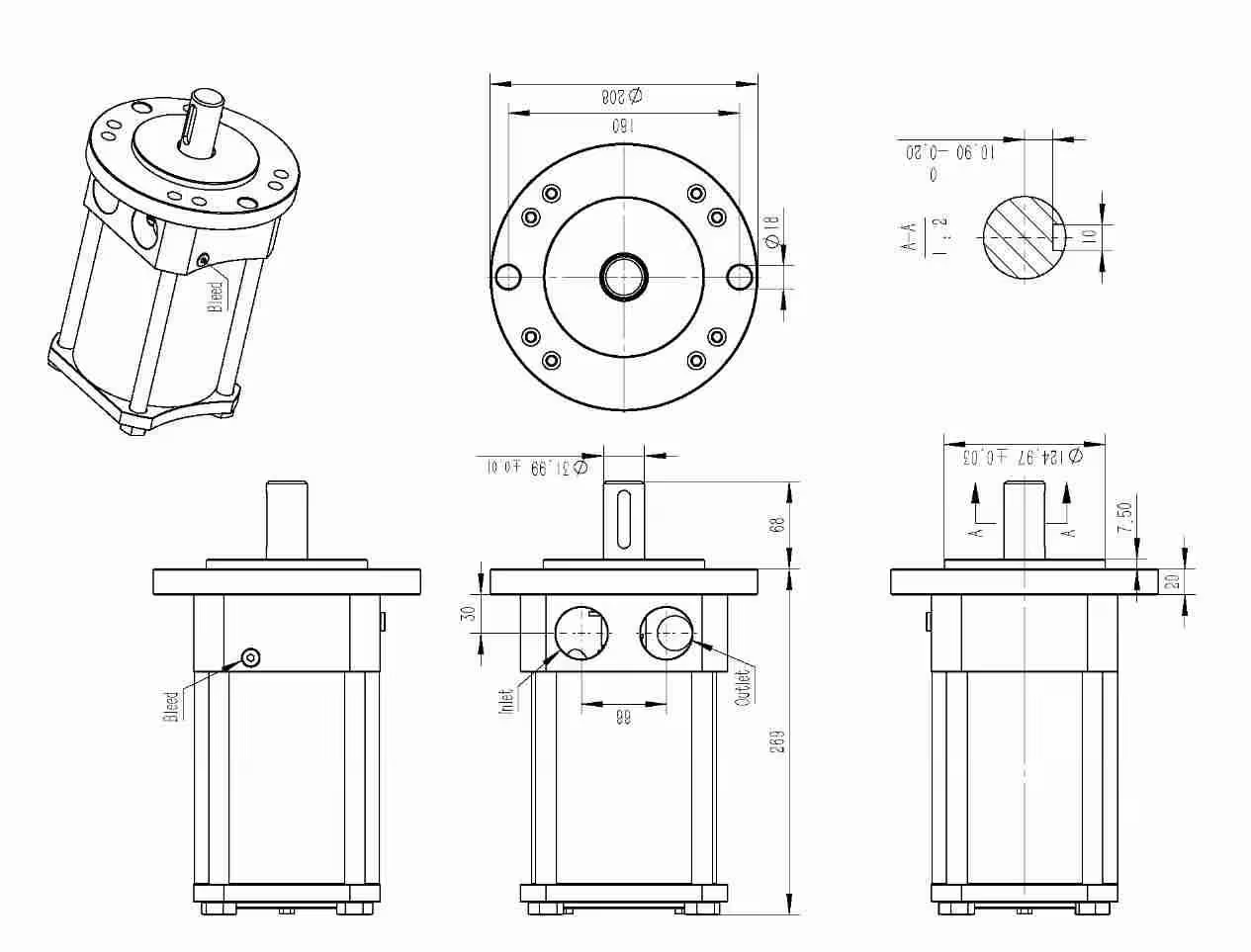

| Pumps Model | 5.1 | 6.5 | 7.2 | 8.2 | 10.2 |

| Displacement (cc/rev) | 51.2 | 65.8 | 71.7 | 80.65 | 101.5 |

| Housing Material | 2205 | 2205 | 2205 | 2205 | 2205 |

| Min. Outlet Pressure(barg) | 20 | 20 | 20 | 20 | 20 |

| Max. Outlet Pressure(barg) | 85 | 85 | 85 | 85 | 85 |

| Inlet Pressure Continuous (barg) | 0.5-5 | 0.5-5 | 0.5-5 | 0.5-5 | 0.5-5 |

| Flow Rate (m3/h) (85barg, 700 rpm) | 1.70 | 2.30 | 2.58 | 3.00 | 3.86 |

| Flow Rate (m3/h) (85barg, 1000 rpm) | 2.8 | 2.58 | 4.00 | 4.64 | 5.85 |

| Flow Rate (m3/h) (85barg, 1200 rpm) | 3.21 | 4.18 | 4.70 | 5.45 | 6.88 |

| Flow Rate (m3/h) (85barg, 1500 rpm) | 4.20 | 5.38 | 6.00 | 6.95 | 8.86 |

| Flow Rate (m3/h) (85barg, 1800 rpm) | 5.04 | 6.45 | 7.22 | 8.30 | 10.50 |

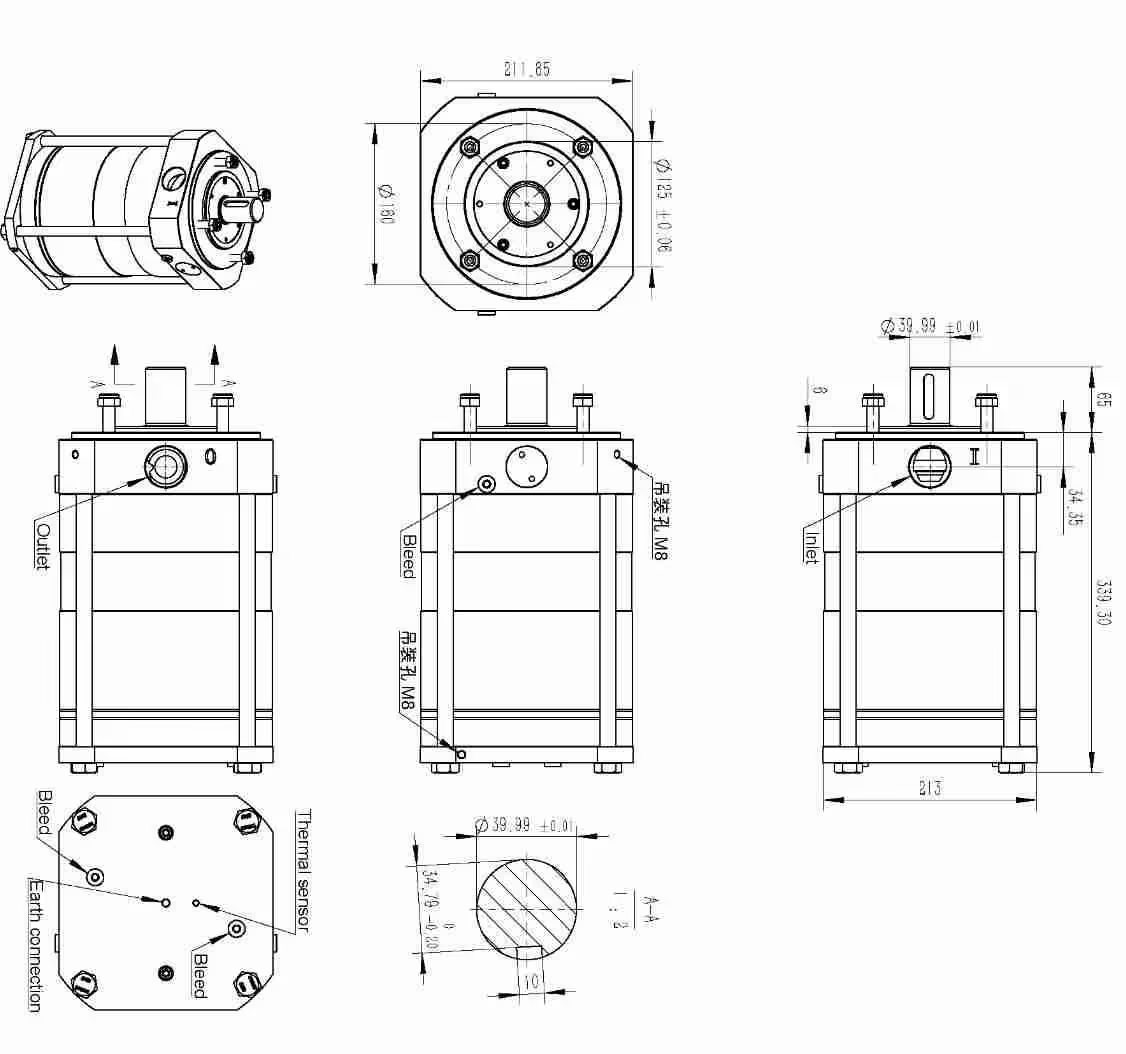

| Pumps Model | 11.0 | 13.0 |

| Displacement (cc/rev) | 138.4 | 169.1 |

| Housing Material | 2205 | 2205 |

| Min. Outlet Pressure(barg) | 10 | 10 |

| Max. Outlet Pressure(barg) | 70 (1500rpm) 85 (1200rpm) | 70 (1500rpm) 85 (1200rpm) |

| Inlet Pressure Continuous (barg) | 2-5 | 2-5 |

| Flow Rate (m3/h) (85barg, 700 rpm) | 4.80 | 6.00 |

| Flow Rate (m3/h) (85barg, 1000 rpm) | 7.50 | 9.24 |

| Flow Rate (m3/h) (85barg, 1200 rpm) | 8.95 | 11 |

| Flow Rate (m3/h) (70barg, 1500 rpm) | 11.26 | 13.85 |

| Pumps Model | 16 | 17 | 19 | 21 |

| Displacement (cc/rev) | 187.3 | 196.4 | 220.3 | 251.96 |

| Housing Material | 2205 | 2205 | 2205 | 2205 |

| Min. Outlet Pressure(barg) | 10 | 10 | 10 | 10 |

| Max. Outlet Pressure(barg) | 70 (1500rpm) 85 (1200rpm) | 70 (1500rpm) 85 (1200rpm) | 70 (1500rpm) 85 (1200rpm) | 70 (1500rpm) 85 (1200rpm) |

| Inlet pressure Continuous (barg) | 2-5 | 2-5 | 2-5 | 2-5 |

| Flow Rate (m3/h) (85barg, 700 rpm) | 7.12 | 7.53 | 8.42 | 9.92 |

| Flow Rate (m3/h) (85barg, 1000 rpm) | 10.6 | 11.18 | 12.58 | 14.58 |

| Flow Rate (m3/h) (85barg, 1200 rpm) | 12.76 | 13.45 | 15.02 | 17.52 |

| Flow Rate (m3/h) (70barg, 1500 rpm) | 16.0 | 16.80 | 18.85 | 21.82 |

| Pumps Model | 22 | 24 | 26 | 31 | 39 |

| Displacement (cc/rev) | 254.5 | 280.6 | 306.8 | 360 | 441.4 |

| Housing Material | 2205/2507 | 2205/2507 | 2205/2507 | 2205/2507 | 2205/2507 |

| Min. Outlet Pressure(barg) | 10 | 10 | 10 | 10 | 10 |

| Max. Outlet Pressure(barg) | 70 (1500rpm) 85 (1200rpm) | 70 (1500rpm) 85 (1200rpm) | 70 (1500rpm) 85 (1200rpm) | 70 (1500rpm) 85 (1200rpm) | 70 (1500rpm) 85 (1200rpm) |

| Inlet Pressure Continuous (barg) | 2-5 | 2-5 | 2-5 | 2-5 | 2-5 |

| Flow Rate (m3/h) (85barg, 700 rpm) | 10.10 | 11.20 | 12.20 | 14.53 | 18.10 |

| Flow Rate (m3/h) (85barg, 1000 rpm) | 14.76 | 16.35 | 17.85 | 21.08 | 26.00 |

| Flow Rate (m3/h) (85barg, 1200 rpm) | 17.80 | 19.68 | 21.46 | 25.40 | 31.45 |

| Flow Rate (m3/h) (70barg, 1500 rpm) | 22.18 | 24.5 | 26.76 | 31.65 | 39.10 |

How to Maintain High-Pressure Pumps for Optimal Performance

Regular maintenance is important to keep your high-pressure pump working well. Good maintenance practices help you keep the pump running smoothly and make it last a long time.

Clean Filters

You need to clean the filters regularly to keep junk from getting into the pump and messing up the inside.

Inspect Seals

Seals are important because the pump runs under high pressure. You need to check the seals regularly and replace them when they wear out to keep the pump efficient.

Monitor Pressure and Temperature

You need to keep the pressure and temperature stable. This keeps the pump from wearing out and helps the system work well.