As an engineer at RohrePumps, I’ve spent years helping clients build fire protection systems in some of the harshest industrial environments—fuel terminals, chemical plants, timber yards, you name it.

One issue kept coming up: hydraulic turbines were holding them back. Too many components, too much maintenance, and not nearly enough flexibility.

That’s why we developed our electric firefighting turbine — a smart, fixed system built for precision, performance, and integration. If you’re tired of hydraulic headaches, this might be the change you’ve been waiting for.

What is a stationary firefighting turbine system?

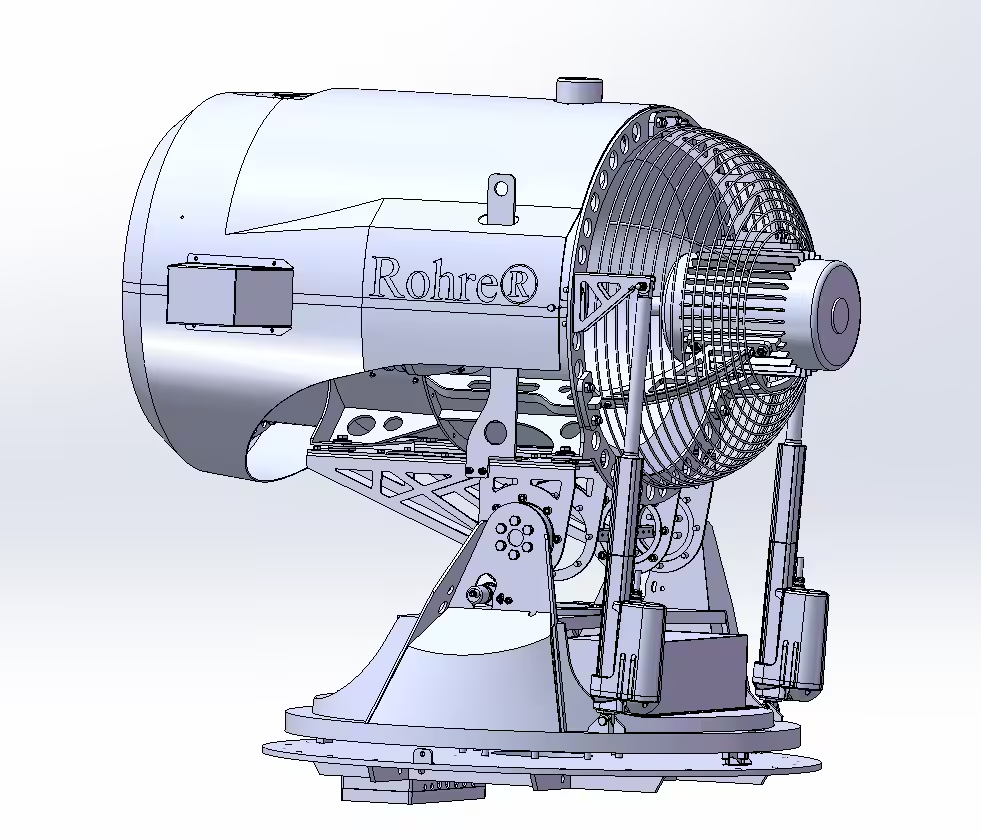

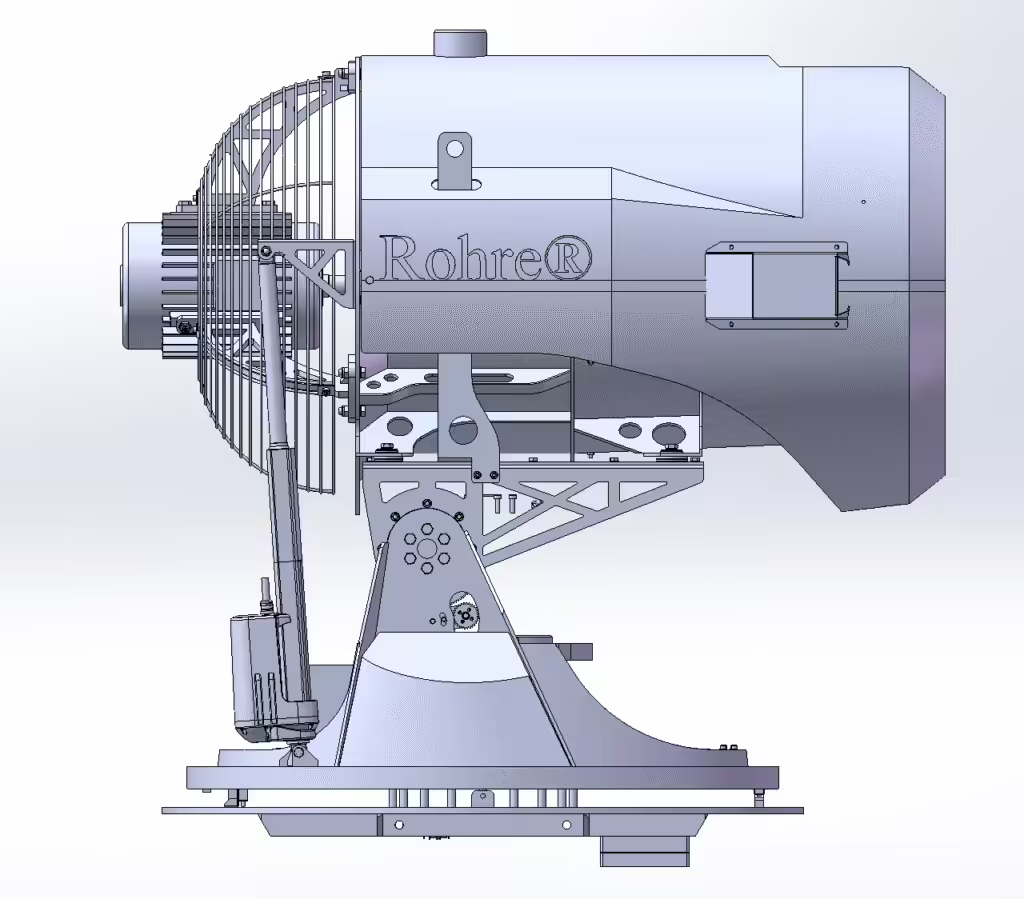

A stationary firefighting turbine is a fixed fire suppression unit that uses a high-power turbine to project fine water mist over long distances. RohrePumps’ electric firefighting turbine model offers 360° coverage, remote control integration, and low maintenance—ideal for high-risk industrial environments.

Our electric firefighting turbine delivers:

- 360° water mist coverage — wide-area suppression

- Fast deployment — instant electric startup

- Remote control compatibility — digital or manual activation

- Integration with fire detection systems — Modbus, dry contact, analog input

Typical Application Scenarios

RohrePumps Firefighting Turbines are ideal for fixed installations in high-risk environments, including:

- Petrochemical storage areas

- Recycling yards and landfill dumps

- Oil and gas terminals and process units

- Chemical production and storage facilities

- Timber processing and woodworking industries

- Large warehouses storing flammable materials

- Aircraft hangars

- Tunnel entrances

- Battery storage or energy hubs

Key Advantages Over Hydraulic Firefighting Turbines

| Feature | RohrePumps Electric | Traditional Hydraulic |

|---|---|---|

| Drive Type | Electric motor | Hydraulic pump + oil lines |

| Installation | Plug & play | Requires high-pressure hydraulic piping |

| Control Integration | PLC / SCADA compatible | Limited or custom |

| Response Speed | Instant electric startup | Delayed response |

| Maintenance | Minimal, no fluid | Requires fluid checks and servicing |

| Environmental Safety | No leakage | Oil leak risk present |

Technical Compatibility

RohrePumps Firefighting Turbine supports integration with:

- NFPA 750-compliant water mist systems

- EN 14972 European standard

- Control via dry contact, Modbus RTU, or analog input

Competitor Comparison: FT10e / MXOne

| Brand | Drive | Installation Complexity | Maintenance | Costs |

|---|---|---|---|---|

| RohrePumps | Electric | Low | Very Low | Low |

| FT10e (EmiControls) | Electric | Low | Low | Medium |

| MXOne (Minimax) | Hydraulic | High | High | Low |

For Fire Protection System Integrators and OEMs

We supply electric firefighting turbine units as key modules to fire suppression system integrators and OEM partners worldwide.

Our goal is to make integration simple, fast, and flexible—whether you’re designing a new system or upgrading an existing fire protection system.

- 🔧 Modular design: Standalone or system-integrated

- 💻 Open protocol: Works with standard fire panels, PLCs, or SCADA systems

- 📊 Full performance data: Jet range, droplet size, pressure profiles

- 📈 Long-term support: Remote commissioning, diagnostics, training

Let us take care of the turbine module, so you can focus on the system as a whole.

1. What is a stationary firefighting turbine system?

A stationary firefighting turbine is a fixed fire suppression system that projects water mist or foam through a high-powered turbine. These systems provide 360° spray coverage and are designed for protecting large industrial areas, such as chemical plants or oil depots.

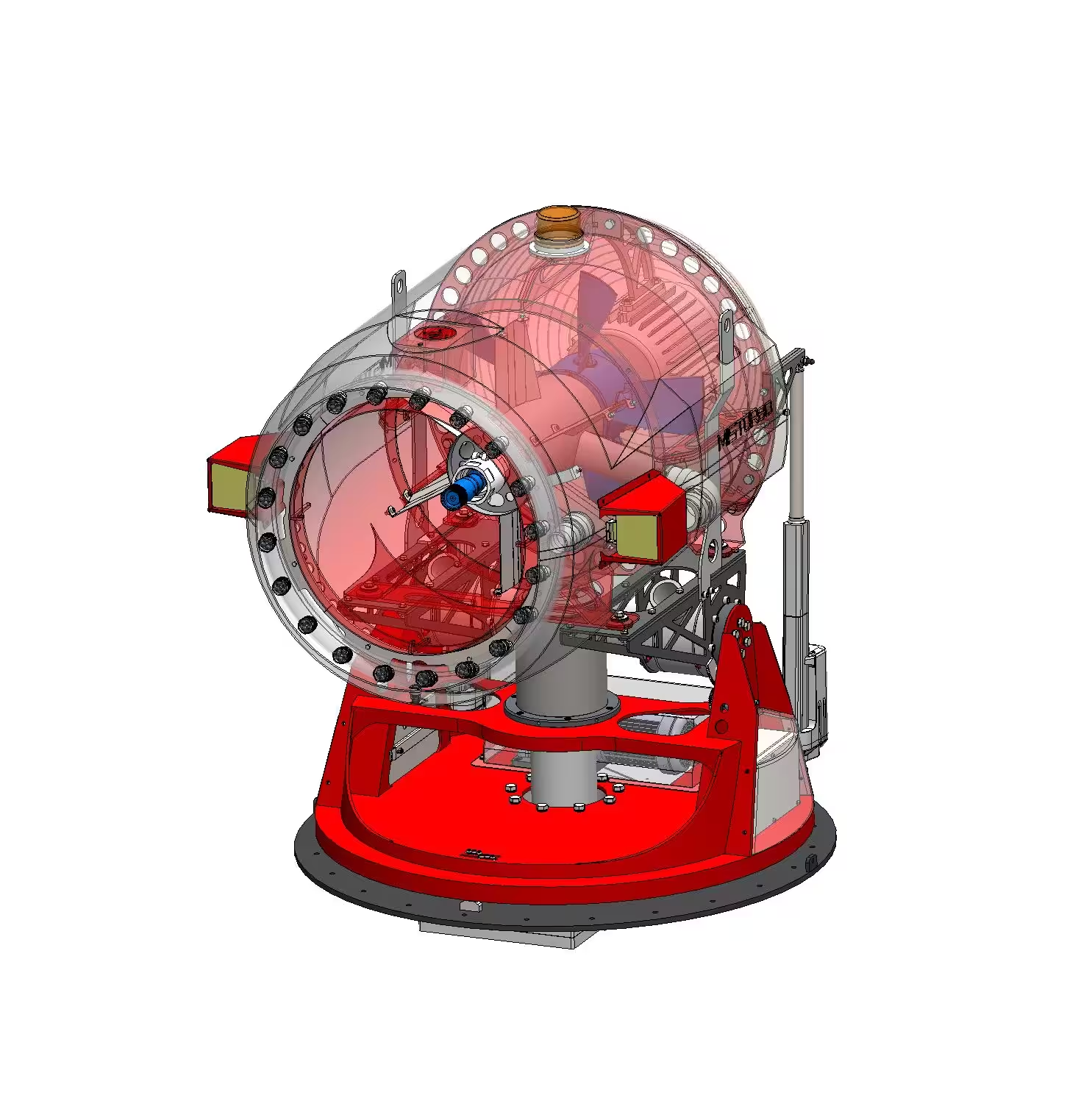

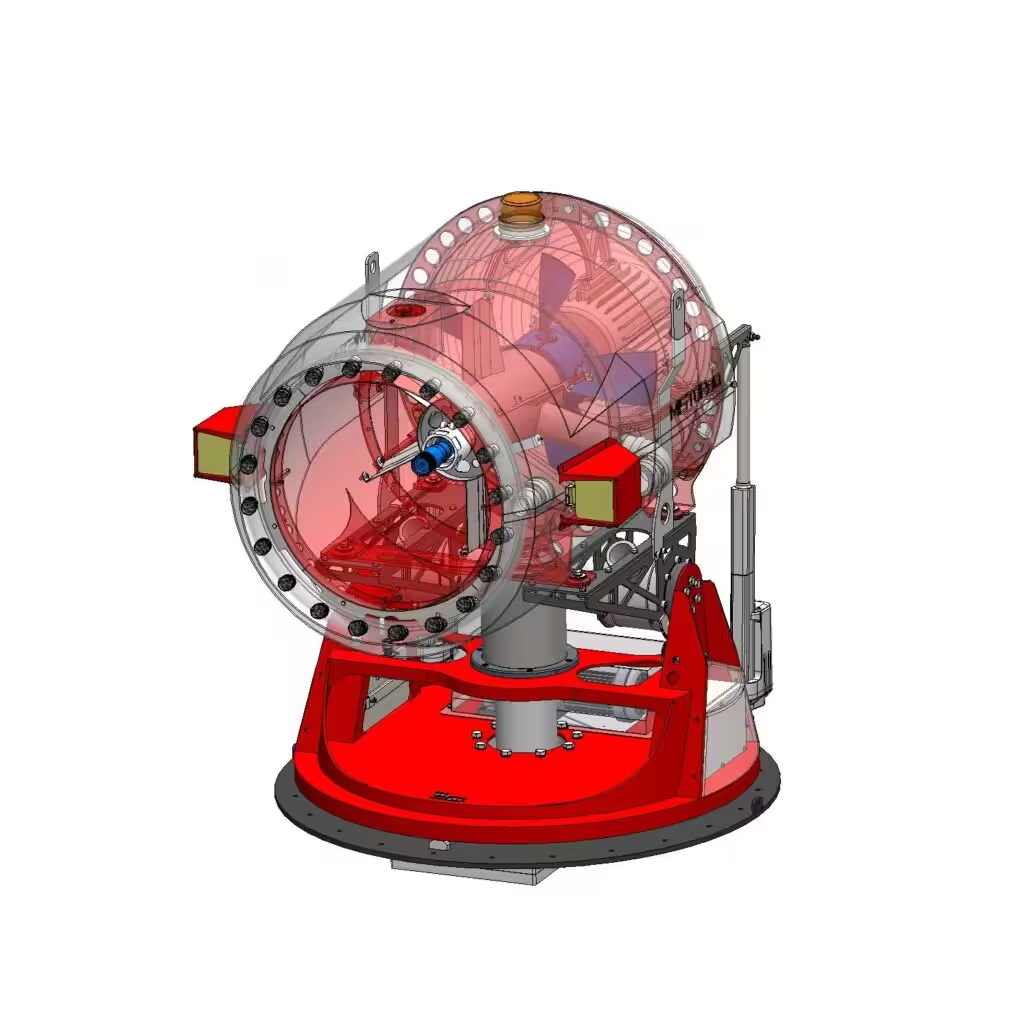

2. How does a firefighting turbine work?

A firefighting turbine uses a powerful fan or motor to propel fine water mist or foam over long distances. The mist envelops the fire source, rapidly reducing temperature and oxygen concentration. Electric versions can be remotely controlled and automatically activated by fire detection systems.

3. What are the advantages of electric firefighting turbines over hydraulic ones?

Electric turbines are easier to install, require no hydraulic lines, and offer better integration with modern control systems. They have faster startup times, lower maintenance, and no risk of fluid leaks—making them ideal for smart industrial environments.

4. What kind of environments are best suited for stationary firefighting turbines?

These systems are ideal for high-risk environments like recycling yards, chemical plants, oil & gas terminals, timber storage, aircraft hangars, and landfill sites—especially where flammable materials are stored in large quantities.

5. Can electric firefighting turbines be integrated with fire detection systems?

Yes. Advanced models like those from RohrePumps support full digital integration via Modbus, dry contacts, or analog signals, allowing seamless connection to fire panels, PLCs, or SCADA systems for real-time control.

6. What standards apply to stationary water mist turbine systems?

They typically comply with NFPA 750 for water mist systems and EN 14972 in Europe. Integration also depends on regional fire codes and the application’s hazard classification.

7. How much does a stationary firefighting turbine system cost?

Pricing ranges from $20,000 to $100,000+ depending on performance specs, coverage radius, fluid type (water/foam), and integration complexity. Electric systems usually offer lower long-term maintenance costs than hydraulic alternatives.

Free Dowoload Water Mist Turbine White Paper

Summary

RohrePumps Firefighting Turbines are designed for system integrators who need performance, reliability, and integration ease.

For new builds or retrofit projects — our electric turbine offers lower lifecycle cost and smarter fire protection. If you’re designing or upgrading a fire protection system and need a high-performance firefighting turbine module, contact us for specs, catalogs, or a technical consultation.

📩 Contact Us

📧 Email: info@rohrepumps.com or marketing@cncontrolvalve.com | RohrePumps is a brand under THINKTANK Group.

🌐 Website: www.rohrepumps.com