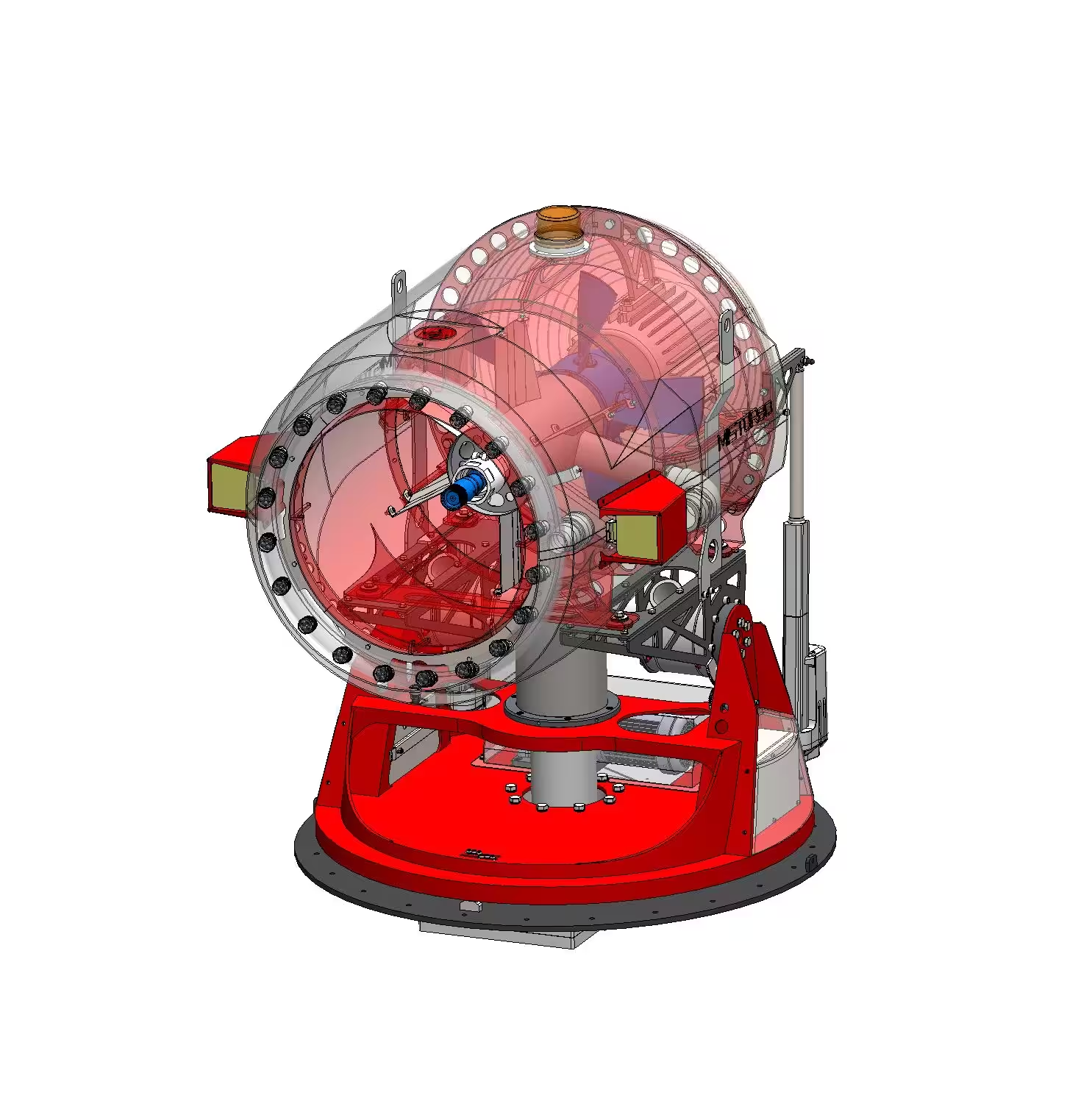

Pressure relief valves play a critical role in protecting axial piston high-pressure pumps and associated systems by ensuring safe and reliable operation under high-pressure conditions. These valves are essential for applications requiring precise pressure control, making them widely used in seawater desalination projects, water mist firefighting systems, high-pressure dust suppression systems, reverse osmosis plants, and other water treatment equipment. By automatically releasing excess pressure, they safeguard equipment from potential damage, enhance operational efficiency, and prolong system lifespan. THINKTANK’s pressure relief valves offer robust performance, precision, and durability, making them an ideal choice for demanding industrial environments.

Table of Contents

ToggleWhat Is the Purpose of a Relief Valve on a Water Pump?

A relief valve is a safety device engineered to open automatically when internal pressures exceed predetermined limits. By discharging excess fluid, it helps maintain a stable environment within your pipelines. It is about ensuring that your pump—particularly if it is a positive displacement type—does not generate unsafe pressures that jeopardize system integrity.

Why Is a Pressure Relief Valve Needed in a Pump?

Relief valves are required because certain pump types, especially positive displacement pumps, can continue generating pressure even when discharge lines are closed. It must be recognized that water is incompressible. In these scenarios, if the fluid has nowhere to go, immense pressure can build rapidly, threatening pump components, seals, and associated piping. By installing a relief valve, your system is safeguarded against such unexpected surges, reducing the risk of downtime, equipment damage, and potential safety hazards.

What Happens If a Pump Does Not Have a Relief Valve?

Without a relief valve, overpressurization scenarios become more likely. Pressure spikes can cause catastrophic failures, from seal damage to cracked housings or burst pipes. In desalination projects, where consistent production of potable water is critical, sudden outages can impact operational targets, disrupt schedules, and cause unwelcome cost overruns.

Which Pumps Require a Relief Valve?

It should be understood that not all pumps are alike. Positive displacement pumps—such as piston, diaphragm, or gear pumps—differ significantly from centrifugal pumps. Positive displacement pumps deliver a fixed volume of fluid per revolution. If the discharge path is blocked, pressure continues to climb. Therefore, a relief valve is almost always required on these pumps. Centrifugal pumps, on the other hand, do not “trap” fluid in the same manner. Although pressure can rise, these pumps are designed to allow fluid to recirculate internally, thus limiting extreme overpressure situations. Nevertheless, adding a relief valve or similar protective devices on centrifugal systems can still provide extra operational safety, especially in sensitive desalination processes.

How Does a Relief Valve Protect the Pump?

Your relief valve protects the pump by ensuring that excessive hydraulic forces never reach critical limits. When the valve senses an overpressure condition, it opens automatically, channeling fluid away from the pump discharge line. By doing so, it prevents internal damage, reduces stress on mechanical components, and preserves crucial sealing surfaces. The pump’s internal parts are spared the wear and tear that would otherwise cut short service life and raise maintenance costs.

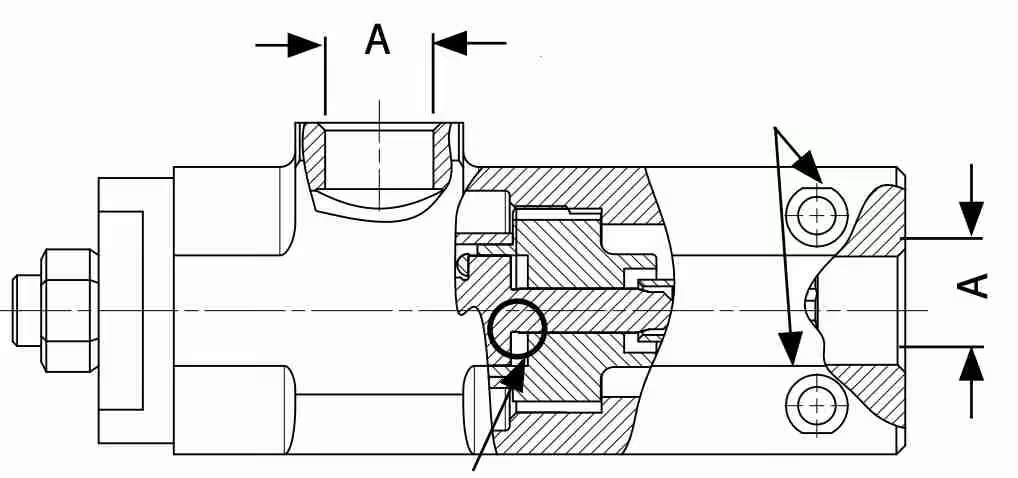

Where Should a Relief Valve Be Installed on a Pump System?

In most configurations, a relief valve is strategically placed on the discharge side of the pump, typically as close to the pump outlet as practical. By positioning it near the source of potential overpressure, the relief valve promptly responds to dangerous conditions. Integrating it directly into your system’s piping design allows for excess fluid to be released safely into a bypass line, return line, or a suitable reservoir. It is crucial that your engineering team or supplier guidelines be consulted to ensure compliance with industry standards and local regulations.

How Do You Select the Right Relief Valve for Your Water Pump?

Selecting the right relief valve involves understanding your system’s normal operating pressures, maximum allowable working pressure, flow rates, and fluid properties. Your chosen relief valve must be sized and rated correctly to handle the maximum expected flow and pressure conditions. Material compatibility is essential, especially in desalination environments where saltwater corrosion resistance is a major concern. By collaborating with experienced suppliers who specialize in desalination solutions, you ensure that your relief valve performs reliably and resists the harsh marine conditions characteristic of saltwater applications.

How Does a Relief Valve Improve Operational Efficiency?

A properly installed relief valve is not just about preventing catastrophic failures—it is also about optimizing efficiency. When pressures remain stable and predictable, pumps operate within their designated performance windows. Stable pressure conditions help your energy consumption remain controlled, your throughput remain consistent, and your water quality remain uncompromised. The valve’s presence leads to a more manageable process environment, potentially reducing the total cost of ownership over the long term.

Can a Relief Valve Help Extend Pump Service Life?

Yes. By continuously preventing harmful overpressure conditions, it is possible to extend your pump’s service life, reduce the frequency of maintenance interventions, and minimize expensive part replacements. When pumps run within safe operating parameters, components suffer less stress and fatigue. Over the lifespan of your desalination plant, the cost savings associated with fewer breakdowns and less downtime can be substantial. The return on investment becomes evident as your pumping system consistently meets project targets without major disruptions.

Is a Relief Valve Necessary in Desalination Applications?

Desalination processes, especially those relying on high-pressure reverse osmosis, place significant demands on pumps. High inlet pressures, corrosive saltwater, and continuous operation raise the stakes. In these conditions, installing a relief valve is more than a recommendation—it is a best practice. By preventing uncontrolled pressure spikes, you safeguard not only your pumps but also the delicate membranes and other expensive desalination system components. The result is higher uptime, better product water quality, and enhanced ROI.

Why Must a Relief Valve Be Properly Maintained?

A relief valve that is not properly maintained may fail to open under critical conditions or may leak unnecessarily, causing operational inefficiencies. Regular inspections, testing, and calibration are recommended so that valve springs, seals, and internal components function optimally. It is also crucial that corrosion and scaling be monitored, as these issues can impede proper valve operation in salt-laden environments. By working with trusted service partners, you ensure that your relief valves remain fit for duty, protecting your system round the clock.

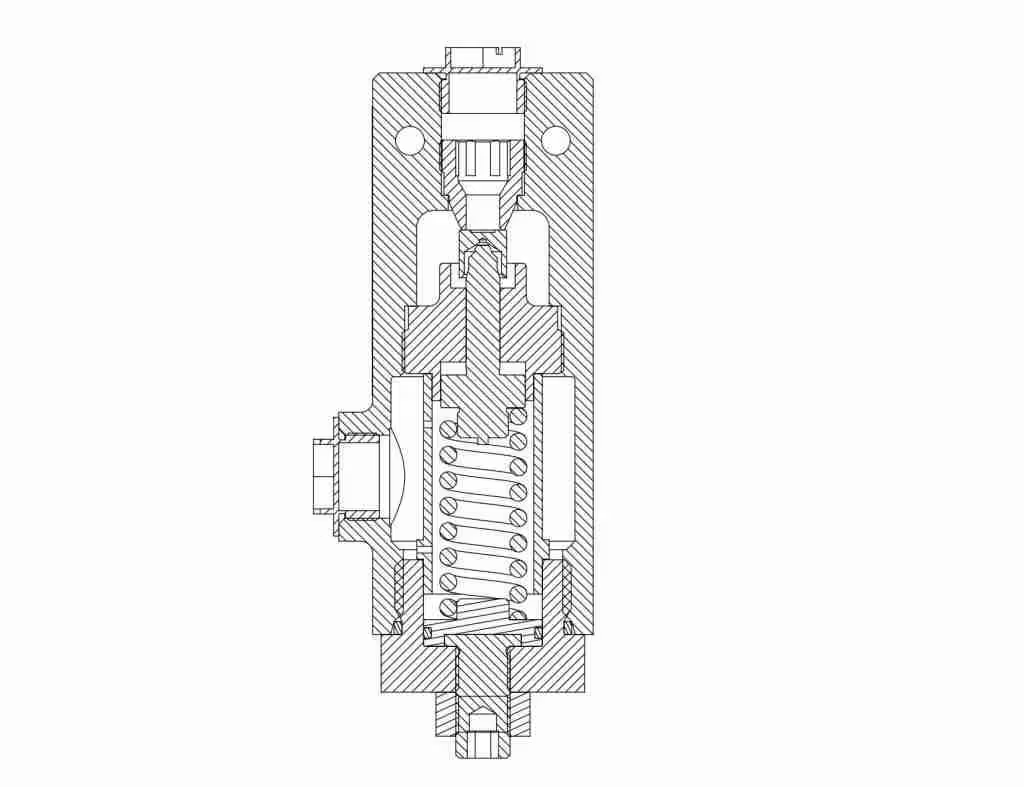

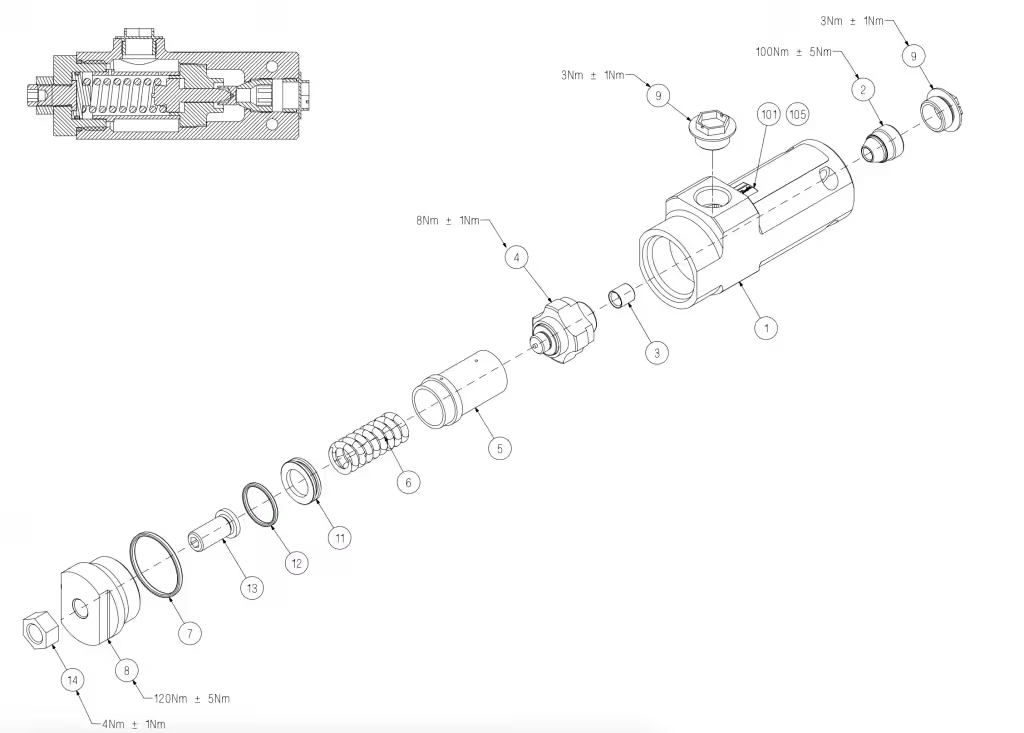

Learn How to Disassembly Pressure Relief Valve From Danforss

screw fully out

Learn How to Assembly Pressure Relief Valve From Danforss

Key Takeaways: Ensuring Pump Performance and Safety

By placing a relief valve on your water pump—especially a positive displacement unit—you gain tangible benefits in performance, safety, and cost efficiency. In your role within the desalination industry, you are tasked with meeting rigorous standards while maintaining tight control over budgets and operational workflows. Relief valves serve as a simple yet powerful mechanism, providing immediate pressure release in critical moments, protecting your investments, and supporting the uninterrupted delivery of safe, potable water. This is not just about adding another component; it is about increasing the resilience and longevity of your entire pumping infrastructure.

In Summary: Relief valves are essential for preventing overpressure conditions that threaten pump integrity, system reliability, and operational safety. By installing and maintaining a properly selected relief valve, you minimize downtime, extend equipment life, and enhance process efficiency. In a competitive B2B desalination landscape, where reliability, quality, and profitability are at the forefront of your priorities, it is clear that incorporating a relief valve is not just advisable—it is integral to your long-term success. Should you have any questions, welcome to contact Rohre pumps team, we are here to happy serve for you.