In seawater desalination systems, reverse osmosis (SWRO) technology has become a widely adopted solution to freshwater scarcity due to its relatively high energy efficiency and compact footprint. Whether it’s a large-scale desalination plant in the Middle East or a compact system on an island or offshore platform, the SWRO pump remains the core component—responsible for pressurizing seawater to the required level for membrane separation. In other words, the selection and performance of the SWRO pump directly impact the system’s output capacity, energy efficiency, and long-term operating cost.

For an SWRO system engineer, choosing a pump is not simply about “meeting specifications.” Real-world project demands are often complex—tight budgets, short delivery timelines, limited maintenance personnel—while still requiring stable, continuous operation in a highly corrosive seawater environment. Faced with these conditions, engineers typically focus on five key questions:

- Is the price reasonable? Not just the purchase price, but also energy consumption, spare parts, and long-term maintenance costs.

- Can the delivery time match the project schedule? Can standardized or modular design accelerate shipment and installation?

- Will the pump operate reliably? Is it suitable for 24/7 continuous operation?

- Is routine maintenance simple and efficient? Is remote monitoring supported? Are spare parts easy to obtain and replace?

- Is the material resistant to seawater corrosion? Especially under extreme conditions like high salinity, temperature, and pressure.

This article explores eight key aspects of SWRO pump selection—including lifecycle cost, delivery time, reliability, maintenance, corrosion resistance, technology comparison, real-world case studies, and engineering recommendations. By combining technical insight with hands-on experience, it aims to help engineers avoid common selection pitfalls and make informed decisions with confidence.

Table of Contents

TogglePrice and Lifecycle Cost

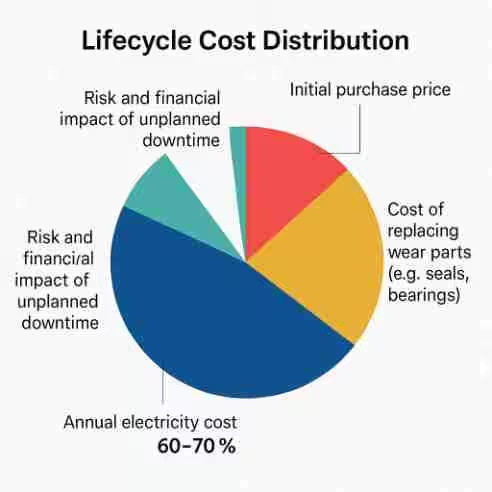

In SWRO projects, pump pricing is often the first decision barrier. But experienced engineers understand that initial cost is just the tip of the iceberg—what truly matters is the total lifecycle cost (LCC), including long-term energy consumption, maintenance, and downtime.

According to data from EUROPUMP and the Hydraulic Institute, energy consumption typically accounts for 60–70% of a pump’s total lifecycle cost over 15 to 20 years, while the equipment’s purchase price often represents less than 15%. In other words, a high-efficiency pump that costs 20% more upfront can pay for itself within three years through lower energy bills.

In addition, the configuration of energy recovery devices (ERDs) and how well they integrate with the pump system can significantly affect the overall energy cost per cubic meter of produced water. Some engineering firms may choose lower-efficiency configurations to reduce the upfront bid price, but this often leads to higher operational costs, reduced membrane life, and ultimately, a higher total cost of ownership.

We recommend that SWRO pump selection incorporate a lifecycle cost evaluation, comparing the 10- or 15-year total cost of different pump options, including:

- Initial purchase price

- Annual electricity cost

- Cost of replacing wear parts (e.g., seals, bearings)

- Labor and routine maintenance cost

- Risk and financial impact of unplanned downtime

Leading pump manufacturers often provide lifecycle cost calculators or reference project data that can be used for realistic comparisons. These tools often offer a far more accurate view of long-term value than looking at price alone.

Delivery Time and Modular Design

In SWRO project execution, equipment delivery time often dictates the overall project schedule—especially for emergency deployments or phased construction plans. A shorter delivery cycle means faster installation, earlier water production, and quicker return on investment.

Axial piston high-pressure pumps feature a compact structure and high part standardization, making them suitable for faster production and shorter lead times. For small and mid-sized SWRO systems, standard axial piston pump models are often available from stock or can be assembled and shipped within 2 to 6 weeks.

More and more engineering companies now adopt multi-train parallel designs (e.g., 6×250 m³/day instead of 1×1500 m³/day). This approach increases system flexibility and redundancy, while also allowing each train to use standardized skids. This not only simplifies production planning but also supports batch delivery to match on-site construction progress.

So standardization + modular delivery makes axial piston pumps ideal for modern SWRO system execution, where speed, scalability, and simplicity are key priorities.

Reliability and Design Life

In SWRO systems, high-pressure pumps must run continuously and reliably—often 24/7 under high salinity and elevated pressure. A single pump failure can halt water production, trigger membrane pressure imbalances, and cause costly downtime. For this reason, reliability isn’t a feature—it’s a baseline requirement.

Axial piston high-pressure pumps are widely recognized for their stable and predictable mechanical design, making them ideal for small and medium-scale SWRO systems where consistency and simplicity are essential. Instead of relying on impellers like centrifugal pumps, axial piston pumps use a direct reciprocating motion to pressurize seawater. Fewer moving parts and linear force transfer allow for smoother operation and easier diagnostics.

Key features that support long service life and reliability include:

- Wear-resistant piston assemblies, often made of ceramic or tungsten carbide, ensuring long-term operation under high pressure and high salinity.

- Stable swash plate drive system, which provides precise and efficient axial motion with minimal vibration.

- Optimized valve plate and cylinder block design, which maintains smooth fluid pathways and reduces pressure loss and internal stress.

- Low vibration and noise, eliminating the need for complex foundation damping.

- Oil-free lubrication options, suitable for clean environments and minimizing the risk of contamination or leakage.

High-quality axial piston pumps are typically designed for Mean Time Between Failures (MTBF) exceeding 20,000 hours. With proper pretreatment and stable operating conditions, many systems run for 2 to 3 years without needing internal inspection or component replacement.

In practice, many SWRO systems adopt N+1 configurations—such as one duty and one standby pump—allowing for rotation and planned maintenance without affecting daily operation. This approach further enhances uptime and system resilience.

Ease of Maintenance and Maintenance Cost

In any SWRO system, the operational phase usually spans 10 to 20 years, and over time, maintenance becomes a major cost driver—especially in remote areas like islands, offshore platforms, or industrial zones with limited service personnel. That’s why maintenance simplicity and speed of recovery are critical factors when selecting a pump.

Compared to multistage centrifugal pumps, axial piston high-pressure pumps are inherently easier to maintain, thanks to their compact structure, fewer components, and modular internal design. Here’s how they deliver operational advantages:

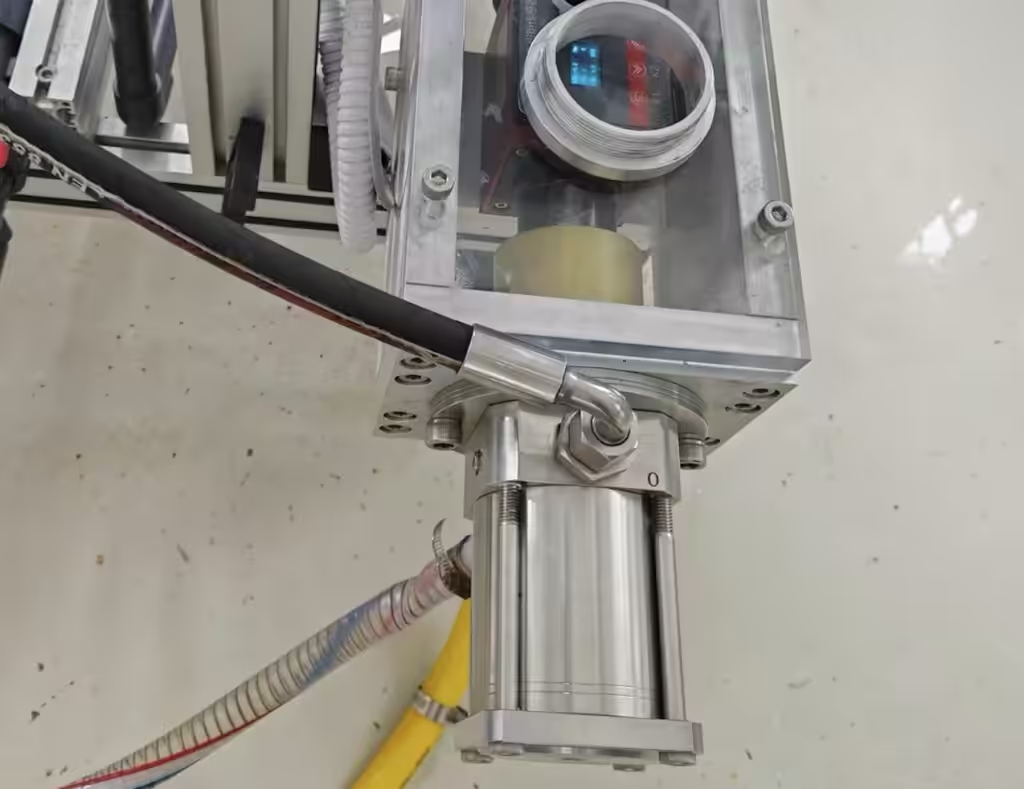

✅ Visual, accessible structure

Key components—such as pistons, seals, and valve plates—are concentrated in the pump housing. These parts can be inspected or replaced by simply removing the front cover, with no need for heavy lifting or full disassembly. Most routine tasks can be done on-site by plant personnel.

✅ Standardized wear parts

Critical consumables such as sealing rings, guide sleeves, and valve springs are standardized across pump models. This simplifies inventory management and ensures fast replacements. Many suppliers offer pre-packed maintenance kits, further reducing downtime and errors during servicing.

✅ Long service intervals

High-quality axial piston pumps typically require only one maintenance check every 6 to 12 months. In systems with good pretreatment and stable operating conditions, some models have operated continuously for 18+ months without part replacement.

✅ Remote monitoring and predictive maintenance

Modern axial piston pumps can be equipped with sensors for vibration, temperature, and pressure. These sensors can be connected to SCADA or PLC systems to support predictive maintenance, allowing engineers to detect anomalies before failure occurs.

✅ Low training requirements

Because of their straightforward structure and standardized maintenance steps, new operators can be trained quickly, enabling localized maintenance teams to perform routine servicing without depending on manufacturer field engineers.

Materials and Corrosion Resistance

Seawater is one of the most aggressive fluids in industrial applications—rich in chlorides, dissolved oxygen, biological contaminants, and various corrosive ions. In SWRO systems, where pumps operate under high pressure and salinity, material selection is critical to long-term reliability and cost control.

Axial piston high-pressure pumps have fewer wetted components than centrifugal pumps, but each contact surface must still be designed to resist corrosion, erosion, and scaling. The following are key material considerations for the major components:

✅ Pump Housing

The pump housing is directly exposed to high-pressure seawater. Common materials include:

- 2205 Duplex Stainless Steel – offers a good balance between strength, cost, and corrosion resistance.

- 2507 Super Duplex Stainless Steel – preferred for harsh seawater environments with high temperatures and salinity.

- Titanium Alloys – used in specialized projects (e.g., offshore, defense) requiring extreme corrosion resistance and zero tolerance for failure.

✅ Pistons and Cylinder Block

The piston assemblies often use ceramic or tungsten carbide-coated materials. These ensure exceptional wear resistance and chemical stability under constant reciprocating motion. The inner surface of the cylinder block is typically precision-ground and polished to prevent micro-cracking and salt buildup.

✅ Valve Plate, Springs, and Valve Seats

These components operate under dynamic stress and must resist pitting and fatigue. Materials such as 316Ti stainless steel, PEEK engineering polymers, or even ceramic valve seats are commonly used to extend service life in corrosive brine.

✅ Sealing Elements

High-pressure seals play a critical role in the overall performance, safety, and service life of a seawater high-pressure pump. Based on practical applications in SWRO systems, two commonly used sealing materials are:

- NBR (Nitrile Rubber): Known for its excellent sealing properties and good resistance to oil, abrasion, and seawater. NBR is cost-effective and widely used in moderate pressure and temperature environments.

- PTFE (Polytetrafluoroethylene): Offers exceptional chemical resistance and a low coefficient of friction, making it ideal for dynamic sealing applications in highly corrosive conditions. PTFE is often used in backup rings or combined with elastomers for improved sealing reliability.

Manufacturers may also provide material variations depending on water quality—for example, open seawater intake versus deep-well brine. Engineers should always prioritize field-proven materials with validated performance in real desalination environments.

If your project involves high salinity, elevated temperatures, or extended operation cycles, investing in reliable seal materials and surface treatments will reduce the risk of failure, minimize maintenance, and help protect the long-term stability of the entire SWRO system.

Technology Comparison: Axial Piston Pumps VS. Multistage Centrifugal Pumps

In SWRO systems, axial piston pumps and multistage centrifugal pumps are both widely used, but they serve different applications based on system scale, layout, and operational needs. One is not necessarily better than the other—they simply fit different use cases.

🔹 Application Overview

- In large SWRO facilities (e.g., >500 m³/h), multistage centrifugal pumps are preferred for their ability to handle high flow rates and integrate efficiently with large-scale Energy Recovery Devices (ERDs).

- For small to mid-size SWRO systems (typically <300 m³/h), especially in islands, ships, containerized plants, or remote areas, axial piston pumps are often the better choice—thanks to their compact size, fast response, short lead time, and easy maintenance.

🔸 Quick Selection Guide

| Project Condition | Recommended Pump Type |

| Total flow > 500 m³/h | Multistage Centrifugal Pump |

| Total flow < 300 m³/h | Axial Piston Pump |

| Tight installation space / skid setup | Axial Piston Pump |

| Short project timeline / urgent lead | Axial Piston Pump |

| Large municipal or industrial plant | Multistage Centrifugal Pump |

| Island, offshore, mobile RO system | Axial Piston Pump |

And here is a side-by-side technical comparison

| Feature | Axial Piston Pump | Multistage Centrifugal Pump |

| Operating Principle | Positive displacement (reciprocating motion) | Dynamic pressure (impeller rotation) |

| Flow Range | Small to medium (≤ 300 m³/h) | Medium to large (> 500 m³/h) |

| Pressure Control | Linear and precise | Depends on flow curve and system pressure |

| Footprint | Compact, skid-friendly | Large, requires more installation space |

| Maintenance | Simple, field-replaceable wear parts | Complex, requires disassembly and alignment |

| Delivery Time | Short, standard models often in stock | Long, typically 4–10 months for custom units |

| Typical Applications | Islands, modular plants, mobile units | Municipal desalination, large RO trains |

Case Study: Rohre Pump in Containerized SWRO System (38 m³/day)

Project Type: 20-foot containerized seawater reverse osmosis system

Application: Potable water production for coastal hotels, schools, real estate developments, and off-grid communities

Production Capacity: 10,085 GPD / 38 m³/day

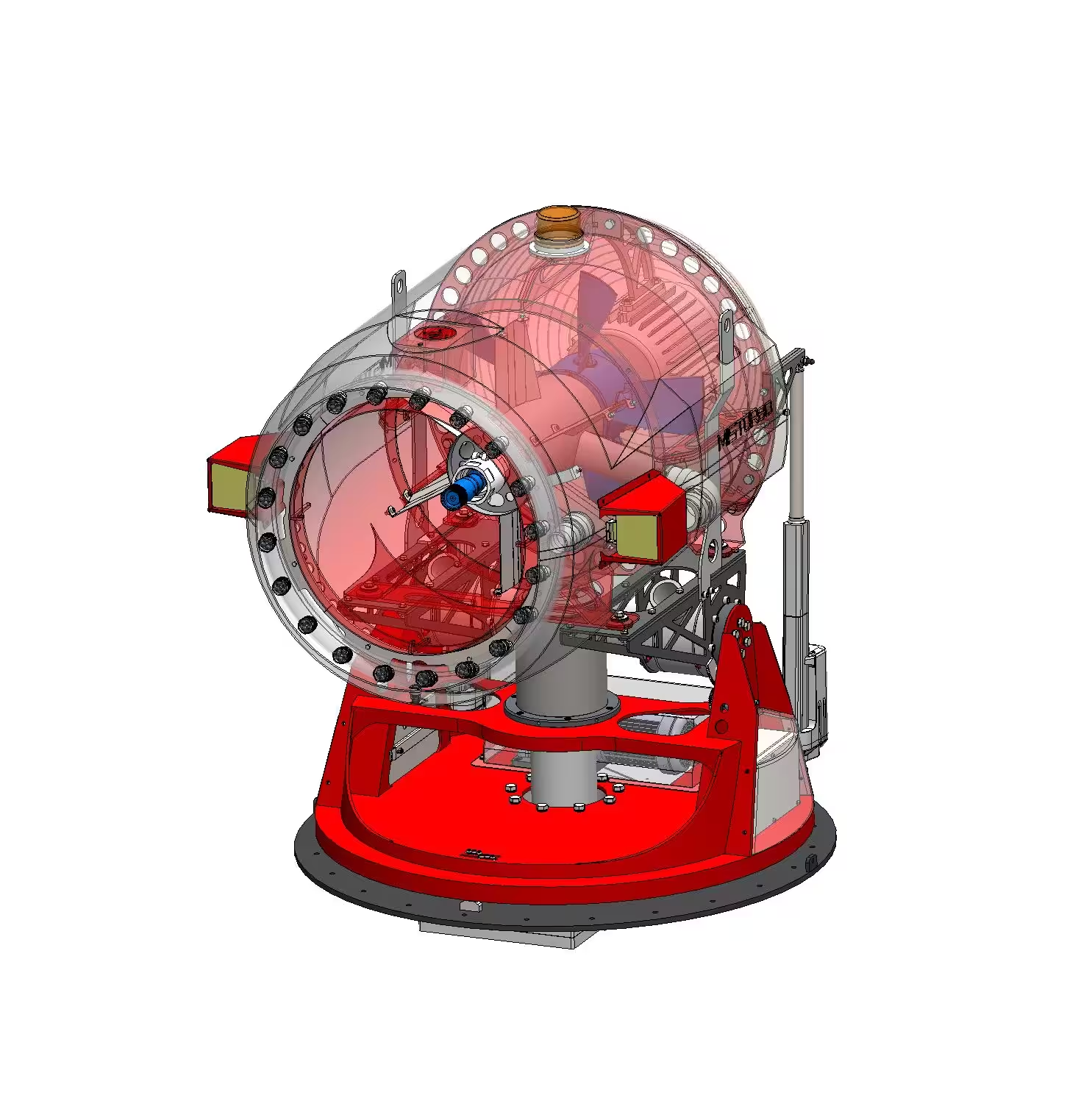

Pump Solution: Rohre axial piston high-pressure pump

Working Pressure: 800–900 psi

Recovery Rate: 26%

Feed Water TDS: ≤ 45,000 ppm

Product Water TDS: ≤ 500 ppm

Power Source: Grid or solar-compatible

System Weight: ~3,750 kg including container

Background

A Singapore.-based SWRO system manufacturer specializing in pre-assembled containerized desalination solutions was seeking a compact, energy-efficient, and corrosion-resistant high-pressure pump for its 38 m³/day unit. The system is designed to serve small-scale decentralized applications, including hotels, schools, golf courses, and residential zones near coastal or off-grid areas.

The customer initially selected a high-end international brand of axial piston high-pressure pump for their containerized SWRO systems. While the performance was reliable, the high unit cost and long lead time became major obstacles as their annual production scaled up.

With nearly 300 pumps required each year, the customer began evaluating alternative suppliers that could meet the same performance standards while improving delivery timelines and cost efficiency.

Rohre was invited to participate in a trial batch. After completing a series of technical inspections and performance tests, our axial piston pump successfully passed all validation procedures. The results met the customer’s expectations for reliability, corrosion resistance, and pressure stability.

Since then, Rohre has become the customer’s approved pump supplier, now providing high-pressure pumps in volume. By switching to Rohre, the customer has reduced their annual pump procurement cost by over 40%, while also shortening lead times and enhancing the overall competitiveness of their SWRO systems in the market.

System Configuration

Pretreatment Section:

- Dual 5-micron sediment cartridge filters (PVC housing)

- Multimedia filter (16″x65″) with automatic backwash

- Acid dosing system to control feedwater pH and prevent scaling

- Antiscalant dosing system with adjustable metering pump

- Feedwater booster pump (316 SS), delivering 40–50 psi inlet pressure

RO Core:

- 3 x 8″ Dow Filmtec or equivalent membranes

- 1000 psi FRP membrane housing

- Rohre axial piston pump, with super duplex stainless steel material

- VFD-compatible 20 HP TEFC motor (220V/380V/460V, 3 Phase)

- High-pressure piping: duplex stainless steel

- Low-pressure piping: Schedule 80 PVC or reinforced tubing

Instrumentation & Controls:

- Digital water quality monitor (TDS for feed and product water)

- Panel-mounted flow meters (feed, product, concentrate)

- Liquid-filled pressure gauges (316 SS)

- Automatic control system with PLC and HMI/LED panel

- Auto start/stop, alarm conditions for pressure, tank level, and shutdowns

- Integrated logic for permeate flush during shutdown/startup

Post-Treatment:

- Chlorine dosing system for product water sterilization

- pH adjustment dosing system for final product pH correction

- TDS-based diversion valve to discard off-spec product water

Results & Performance

Not only 38m3/day containerized systems, Rohre axial piston high pressure pumps are also used in 27m3/day, 120m3/day, 200m3/day, 250m3/day, 300 M3/Day containerized SWRO systems, which are widely used in Schools, Hotels, Golf Courses, Irrigation, Factories, Hospitals, Real Estate Developments, Housing subdivisions and other scenarios.

After extensive technical verification and long-term performance evaluation, Rohre’s axial piston pumps are officially approved as the customer’s preferred high pressure pump supplier. Since adoption, these pumps have been providing excellent reliability, with no serious failures reported during full load continuous operation.

By switching from a well-known international brand to Rohre’s axial piston pumps, the customer achieved:

- Reduced annual pump procurement costs by more than 40%

- Shorter delivery times, reduced project lead times, and faster system deployment

- Increased internal profit margins and system competitiveness in a cost-sensitive global market

Operators also report that Rohre pumps are quiet, compact, and easy to service, with clear maintenance access and standard spare parts available. The successful implementation has established Rohre as a long-term strategic pump partner, currently supplying nearly 300 pumps per year to support the customer’s growing system needs.

Engineering Recommendations

Based on the key factors discussed—price, delivery time, reliability, maintenance, and corrosion resistance—axial piston high-pressure pumps have proven to be a reliable and cost-effective choice for small to medium-scale SWRO systems. For engineers involved in system design, equipment selection, or long-term operation planning, we offer the following practical recommendations:

✅ a. Consider total lifecycle cost (LCC), not just the purchase price

A slightly more expensive, high-efficiency pump can pay off quickly through energy savings and reduced downtime. Include energy use, maintenance, spare parts, and failure risk in your evaluation.

✅ b. For projects with tight schedules, use pre-engineered skid-mounted modules

Axial piston pumps are highly compatible with modular systems and are often available in stock. This significantly reduces delivery and on-site installation time.

✅ c. Use axial piston pumps for flow rates below 300 m³/h

In small and mid-scale SWRO systems, piston pumps offer better efficiency, a smaller footprint, and simpler control compared to centrifugal pumps.

✅ d. Choose materials with proven seawater resistance

Pump housing made from 2205/2507 duplex stainless steel or titanium alloys, along with ceramic pistons and corrosion-resistant valves, will ensure long-term durability.

✅ e. Prioritize standardization and maintainability

Select pump models with interchangeable wear parts and field-replaceable components. Maintenance kits and on-site serviceability will reduce long-term O&M costs.

✅ f. Design for redundancy when possible

An N+1 pump configuration (e.g., 1 duty + 1 standby) minimizes risk and allows for scheduled maintenance without interrupting system operation.

✅ g. Choose suppliers with real SWRO project experience

Work with manufacturers who have proven field performance, can provide reference cases, and understand the operational challenges of desalination systems.

Final Thought

In seawater reverse osmosis systems, the high-pressure pump is not just a mechanical component—it defines the system’s core performance, energy consumption, and operational reliability. Choosing the right pump affects not only the short-term output but also the long-term total cost of ownership, system uptime, and client satisfaction.

Rohre axial piston high-pressure pumps have been validated in a wide range of SWRO installations, providing reliable performance, corrosion resistance, and modular compatibility for fast-track projects. Whether you’re working on a containerized unit or a distributed desalination network, Rohre offers engineering-driven selection guidance, standardized configurations, and flexible customization options.

If you’re designing your next SWRO system and need a pump partner who understands both the technical and commercial challenges, we invite you to connect with Rohre team.

Let’s build desalination systems that last longer, perform better, and cost less over time.