In a reverse osmosis (RO) system, the high-pressure line is where everything gets serious. If your hose or connector isn’t up to spec, you’re risking leaks, pressure drops—or worse, damage to your membranes and system downtime. As a manufacturer of industrial RO high pressure pumps, we get asked all the time:

“What hose should I use for this pump?”

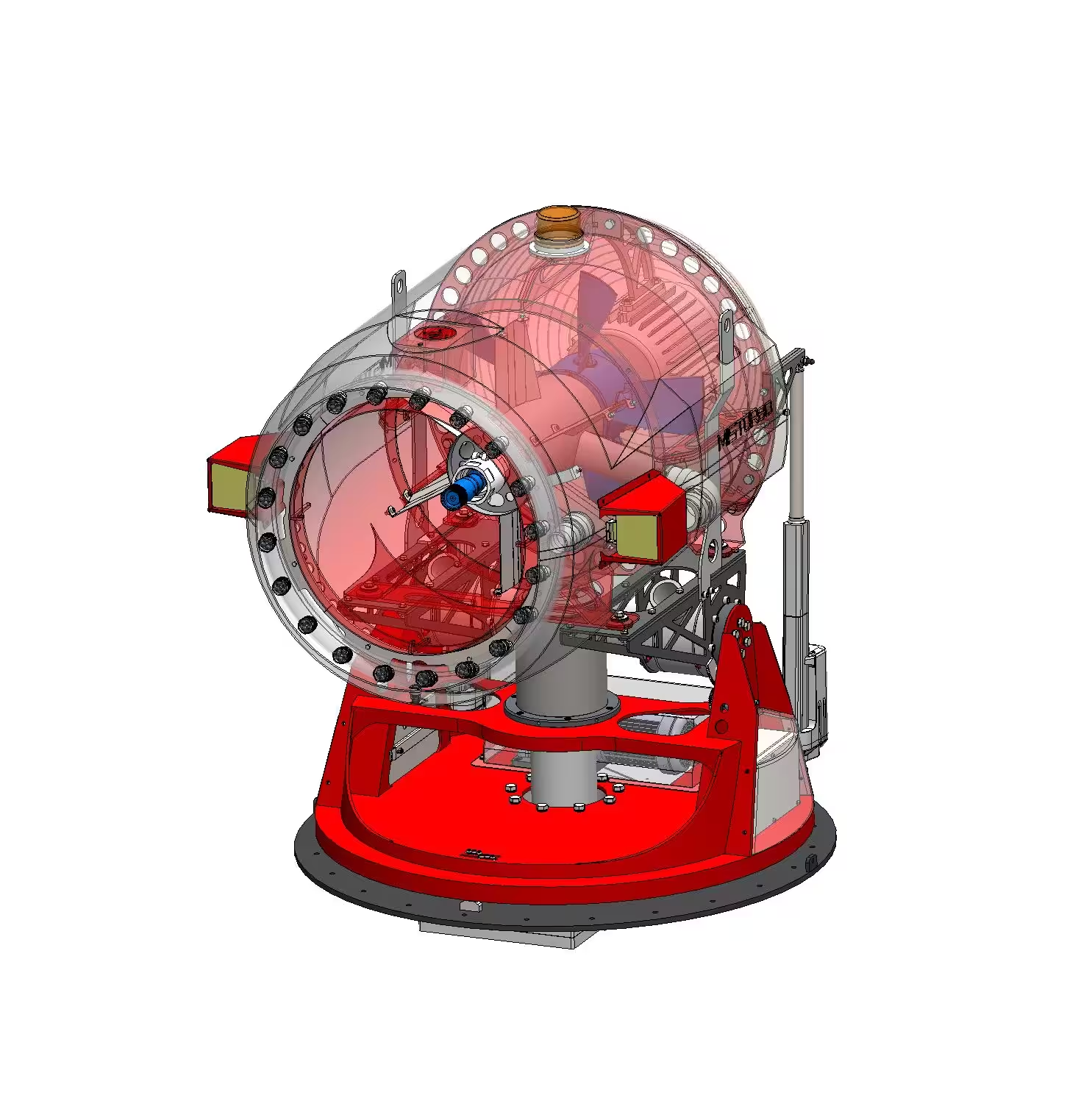

Here’s our engineer-backed answer, based on years of system design and field data, using our Rohre RO High Pressure Pump as the baseline.

For our pumps, we recommend hoses rated for 8–16 MPa (up to 2320 psi), equipped with stainless steel end fittings (DN20–DN50). Depending on the pump model, we use 2205 duplex, 304, or 316L stainless steel. These materials hold up to aggressive fluids like seawater and high-salinity wastewater—just the kind of stuff RO systems deal with daily.

🔍 High Pressure Hose Connector Technical Specs You Should Know

Here’s what our typical high-pressure hose setup looks like:

| Parameter | Specification |

|---|---|

| Coupling Size | DN20, DN25, DN32, DN40, DN50 |

| Fitting Material | 2205/2507 Duplex Steel (HPS Seawater High Pressure Pump) |

| 304/316L Stainless Steel (HPH Tap Water High Pressure Pump) | |

| Compatible Media | Seawater, High-Salt Wastewater, Tap Water, Brackish Water |

| Max Pressure | 8.5 MPa for HPS |

| 16.0 MPa for HPH |

We pressure test every hose assembly before it leaves the factory, and the fittings are machined with multi-groove geometry for secure crimping and zero-slip performance under load.

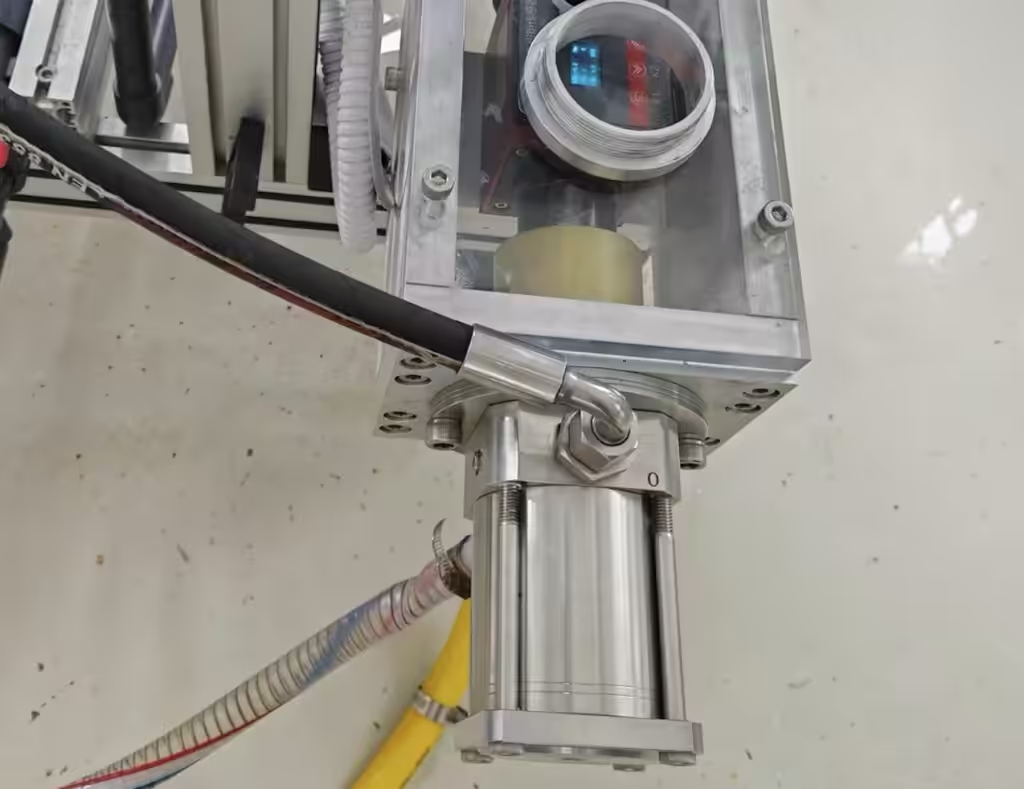

🔧 Installation Notes from the Field

Installation’s not rocket science, but here’s what we recommend for long-term reliability:

- Match the DN size properly—don’t “make it work” with thread tape or adapters. That’s a leak waiting to happen.

- Tighten fittings evenly, especially when you’re using stainless threads. Over-torquing can wreck the threads or distort the seal.

- If you’re connecting two hoses, make sure the intermediate fitting matches the pressure class—don’t mix ratings.

💡 Our hoses come pre-assembled and matched to our pump ports, so most installers find setup takes just a few minutes.

📐 What Hose Size Should You Choose?

We usually match hoses to pump model like this:

| Pump Type | Recommended Hose | Pressure Rating |

|---|---|---|

| HPS (for seawater) | DN25 or DN32 | ≥8 MPa |

| HPH (for tap water) | DN25 to DN40 | ≥16 MPa |

| HPB (for technical water) | DN32 to DN50 | ≥16 MPa |

The hose itself? We use:

- Thick rubber outer layer

- Steel wire reinforcement

- Crimped stainless ends

This combo handles high pulsation from piston pumps and resists fatigue in vibration-heavy installs.

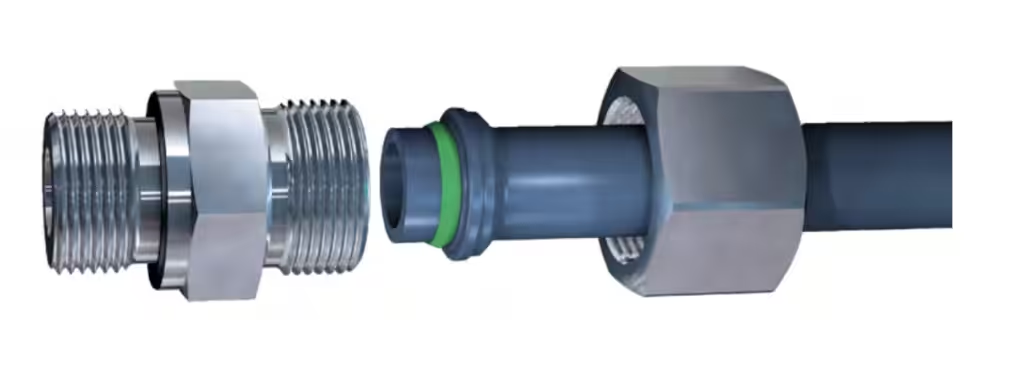

Visual Reference: What It Looks Like

Here’s a quick look at what our hose setups include:

- Ribbed stainless steel connectors (various DN sizes)

- Black high-pressure rubber hose with reinforced inner core

- Crimped stainless fittings, tested up to 16 MPa

Everything’s factory-tested. No guesswork on your end.

Final Word from Engineering

If you want your RO system to perform like it should, don’t cheap out on hose assemblies. They’re just as critical as the pump and membrane. We’ve engineered our Rohre RO High Pressure Pump hose kits to meet the pressure, chemical, and durability demands of real-world installations—seawater, wastewater, brine, you name it.

Need help sizing or sourcing the right hose set for your pump? Drop us a line. We’ll make sure your system is built to run right the first time.